Preparation method of 1, 4-naphthalene dicarboxylic acid

A technology of naphthalene dicarboxylic acid and naphthalene ethyl ketone, applied in the field of preparation of 1,4-naphthalene dicarboxylic acid, achieving good economic benefits, easy operation, and simple preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

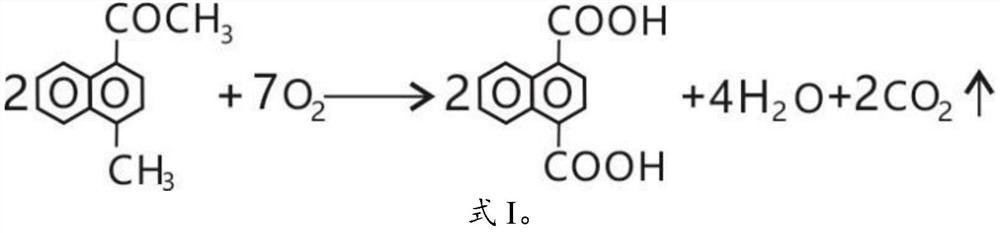

[0018] The invention provides a preparation method of 1,4-naphthalenedicarboxylic acid, comprising the following steps:

[0019] Mix 1-methyl-4-naphthalene ethyl ketone, a solvent and a catalyst, and feed oxygen into the obtained mixed solution to make 1-methyl-4-naphthalene ethyl ketone undergo an oxidation reaction to obtain 1,4-naphthalenedicarboxylic acid .

[0020] In the present invention, the catalyst includes cobalt acetate, manganese acetate and potassium bromide, and the present invention simultaneously uses the above three substances as catalysts, which can catalyze the oxidation reaction to proceed smoothly.

[0021] In the present invention, the solvent is glacial acetic acid; the mass ratio of the 1-methyl-4-naphthoethyl ketone, cobalt acetate, manganese acetate, potassium bromide, glacial acetic acid and oxygen is preferably 100:(3~5 ):(3-5):(3-5):(1400-1600):(80-100), more preferably 100:4:4:4:1500:90.

[0022] In the present invention, the introduction rate ...

Embodiment 1

[0037] Drop into 100kg 1-methyl-4-naphthalene ethyl ketone, 4kg cobalt acetate, 4kg manganese acetate, 4kg potassium bromide, 1500kg glacial acetic acid in the glass-lined reactor of 2000L band condenser, oxygen supply pipe and tail gas absorption device, start Stir and heat up to 100 ° C, feed 90 kg of oxygen at a constant speed, stop the oxygen when the 1-methyl-4-naphthoethyl ketone is controlled to be less than 0.5% in the sampling, cool down to 30 ° C, and spin dry to obtain a crude wet weight of 150 kg to be refined; Into the reactor, measure the water content and add acetic anhydride according to the water content in the mother liquor, if the mother liquor is not enough, add glacial acetic acid to 1500L, add 0.2kg cobalt acetate, 0.2kg manganese acetate, 0.2kg potassium bromide, 100kg 1 -Methyl-4-naphthoethyl ketone, then operate with the batch reaction.

[0038] Add 150kg of the above-mentioned crude product and 2000L of water to the 3000L glass-lined reactor, heat up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com