Low-reflectivity wave-absorbing material and preparation method thereof

A wave-absorbing material and low-reflection technology, applied in the field of wave-absorbing materials, can solve the problem of small impact on firepower performance, and achieve the effects of wide absorption frequency band, simple and efficient process, and low surface density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

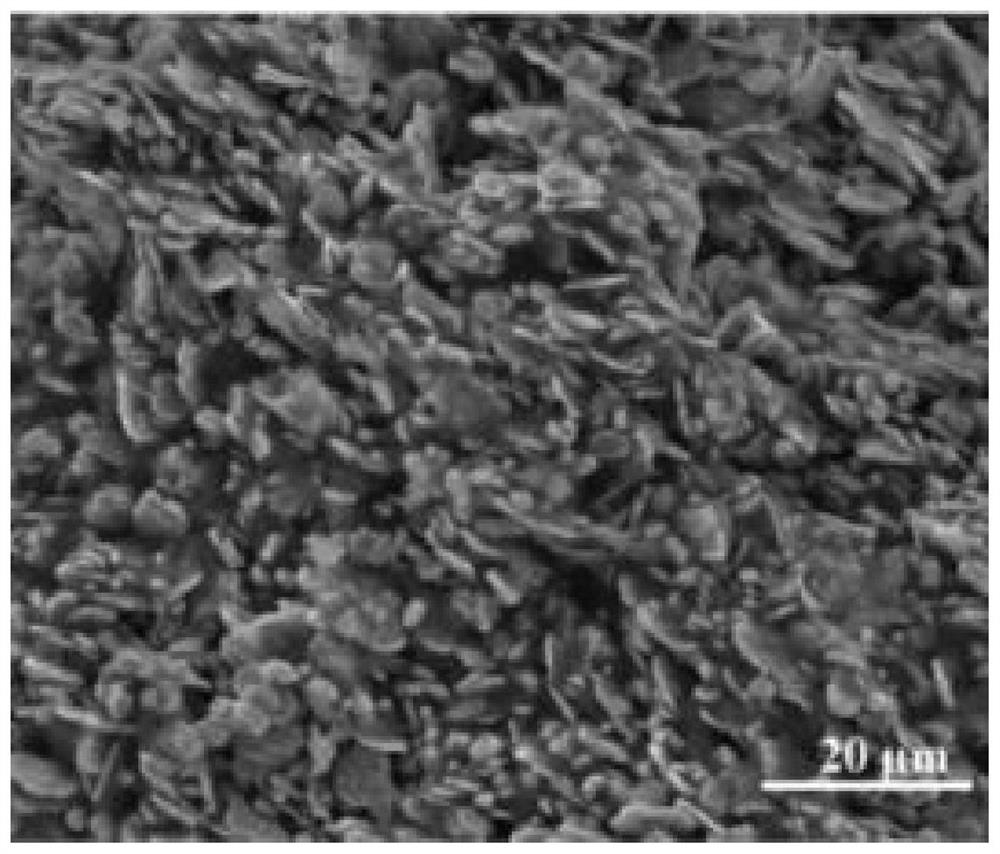

Image

Examples

Embodiment 1

[0023] A low-reflectivity wave-absorbing material and a preparation method thereof, comprising the following steps,

[0024] Step 1. Weigh the carbonyl iron, and slowly add the carbonyl iron to the aqueous solution of the bluing oxidant under the condition of heating in an oil bath at 140°C. The mass ratio is configured. The mass ratio of carbonyl iron to blue oxidant is 1:1. During the reaction, stir with a mechanical stirrer at a speed of 320r / min. After 60 minutes of reaction, pour out the supernatant and wash it repeatedly with distilled water , put it in a vacuum drying oven at 80°C and dry it for later use to prepare carbonyl oxide iron powder;

[0025] Step 2. Weigh 3-aminopropyltriethoxysilane and add it to absolute ethanol. At the same time, add the carbonyl iron oxide powder dried in step 1 into deionized water, and ultrasonically oscillate for 30 minutes to make it into a carbonyl iron suspension. , the carbonyl iron suspension is added to the ethanol solution of 3...

Embodiment 2

[0030] A low-reflectivity wave-absorbing material and a preparation method thereof, comprising the following steps,

[0031] Step 1. Weigh the carbonyl iron, and slowly add the carbonyl iron to the aqueous solution of the bluing oxidant under the condition of heating in an oil bath at 140°C. The mass ratio is configured. The mass ratio of carbonyl iron to blue oxidant is 1.25:1. During the reaction, stir with a mechanical stirrer at a speed of 320r / min. After 60 minutes of reaction, pour out the supernatant and wash it repeatedly with distilled water , put it in a vacuum drying oven at 80°C and dry it for later use to prepare carbonyl oxide iron powder;

[0032] Step 2. Weigh 3-aminopropyltriethoxysilane and add it to absolute ethanol. At the same time, add the carbonyl iron oxide powder dried in step 1 into deionized water, and ultrasonically oscillate for 30 minutes to make it into a carbonyl iron suspension. , the carbonyl iron suspension is added to the ethanol solution o...

Embodiment 3

[0037] A low-reflectivity wave-absorbing material and a preparation method thereof, comprising the following steps,

[0038] Step 1. Weigh the carbonyl iron, and slowly add the carbonyl iron to the aqueous solution of the bluing oxidant under the condition of heating in an oil bath at 140°C. The mass ratio is configured. The mass ratio of carbonyl iron to blue oxidant is 1.5:1. During the reaction, stir with a mechanical stirrer at a speed of 320r / min. After 60 minutes of reaction, pour out the supernatant and wash it repeatedly with distilled water , put it in a vacuum drying oven at 80°C and dry it for later use to prepare carbonyl oxide iron powder;

[0039] Step 2. Weigh 3-aminopropyltriethoxysilane and add it to absolute ethanol. At the same time, add the carbonyl iron oxide powder dried in step 1 into deionized water, and ultrasonically oscillate for 30 minutes to make it into a carbonyl iron suspension. , the carbonyl iron suspension is added to the ethanol solution of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com