3D multi-layer high-flux organ chip and preparation method and application thereof

An organ-on-a-chip, high-throughput technology, applied in biochemical equipment and methods, biochemical instruments, bioreactor/fermenter combinations, etc., to achieve the effects of high-throughput operation and characterization, simple methods, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0105] In the second aspect of the embodiments of the present invention, a method for preparing a 3D multilayer high-throughput organ chip includes the following steps:

[0106] S11, washing the liquid storage layer 10, the film layer 20 and the 3D culture layer 30 respectively, and then drying;

[0107] S12, using liquid PDMS glue to sequentially stack and bond the film layer and the 3D culture layer to one side of the liquid storage layer to obtain a prefabricated three-layer chip;

[0108] S13. Dry the prefabricated three-layer chip to obtain a three-layer chip; complete the preparation of a 3D multi-layer high-throughput organ chip to obtain a 3D multi-layer high-throughput organ chip.

[0109] According to the preparation method of the embodiment of the present invention, the prepared 3D multilayer high-throughput organ chip has three layers, including a liquid storage layer 10 , a thin film layer 20 and a 3D culture layer 30 that are sequentially stacked and connected (b...

Embodiment 1

[0151] Example 1 3D multilayer high-throughput organ chip I

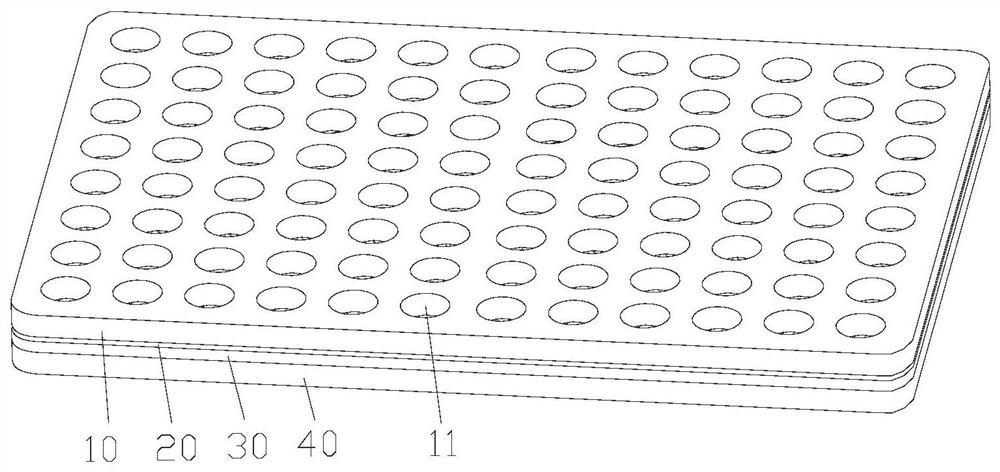

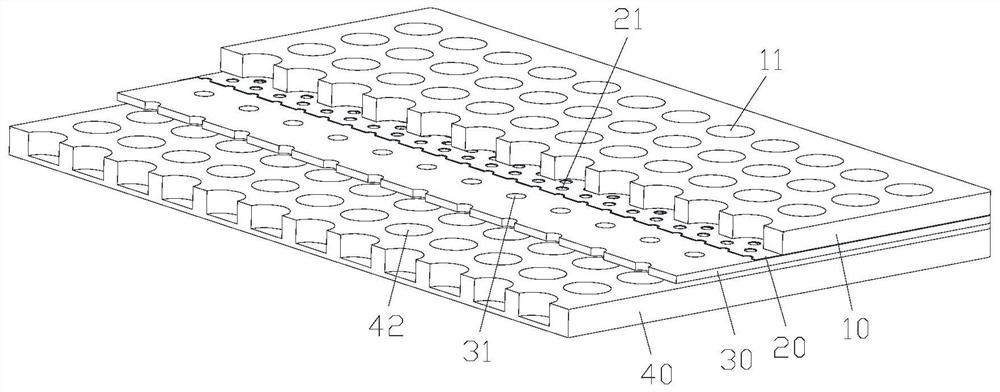

[0152] Such as Figure 1 to Figure 2 As shown, the 3D multi-layer high-throughput organ chip I includes a liquid storage layer 10 , a film layer 20 and a 3D culture layer 30 that are stacked and connected in sequence.

[0153] Wherein, the liquid storage layer 10 is a liquid storage plate with holes (such as a PMMA plate), and the liquid storage through hole 11 is a through hole opened on the body of the liquid storage plate. The liquid storage through hole 11 is a circular straight hole (cylindrical hole) with a diameter of 6 mm and a depth of 3 mm.

[0154] The film layer 20 adopts a polycarbonate film (PC film) with micropores 21 and a pore diameter of 0.4 μm.

[0155] The 3D culture layer 30 adopts a culture plate with holes (eg, PMMA plate), and the culture microwells 31 are through holes opened on the body of the culture plate. The culture microwell 31 is a circular straight hole (cylindrical hole) with a d...

Embodiment 2

[0157] Example 2 3D multilayer high-throughput organ chip II

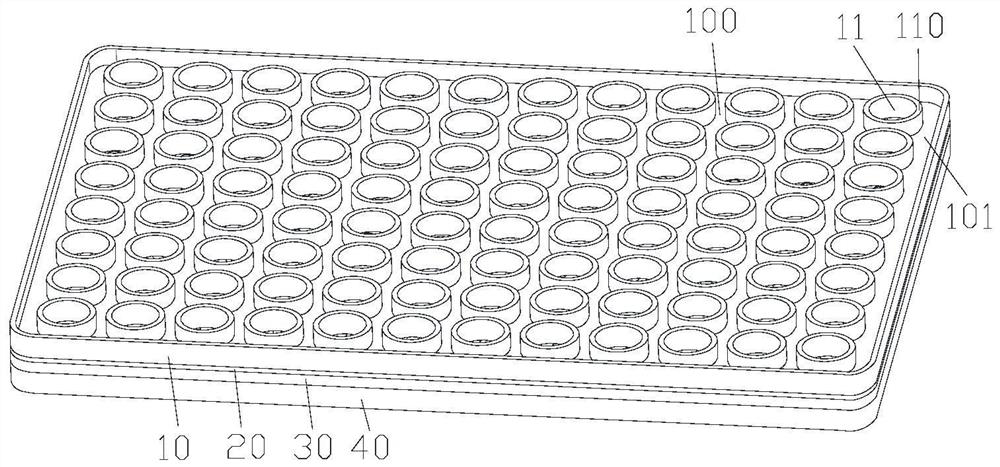

[0158] Such as Figure 3 to Figure 4 As shown, the 3D multi-layer high-throughput organ chip II includes a liquid storage layer 10 , a film layer 20 and a 3D culture layer 30 that are sequentially stacked and connected.

[0159] Wherein, the surface of the liquid storage layer 10 has a plurality of protrusions protruding from the surface (ie, the cylinder portion 110 ), and through holes are opened on the protrusions to form a plurality of liquid storage cylinder holes 11 . A frame 102 is formed on the liquid storage layer around the through-hole liquid storage area (composed of a plurality of liquid storage column holes 11 ) to form a liquid storage tank 100 . Moreover, the liquid storage column holes 11 are located in the liquid storage tank 100 . That is, the liquid storage layer 10 is a tank plate (for example, made of PMMA) with liquid storage column holes. Wherein, a gap 101 is provided between the liquid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com