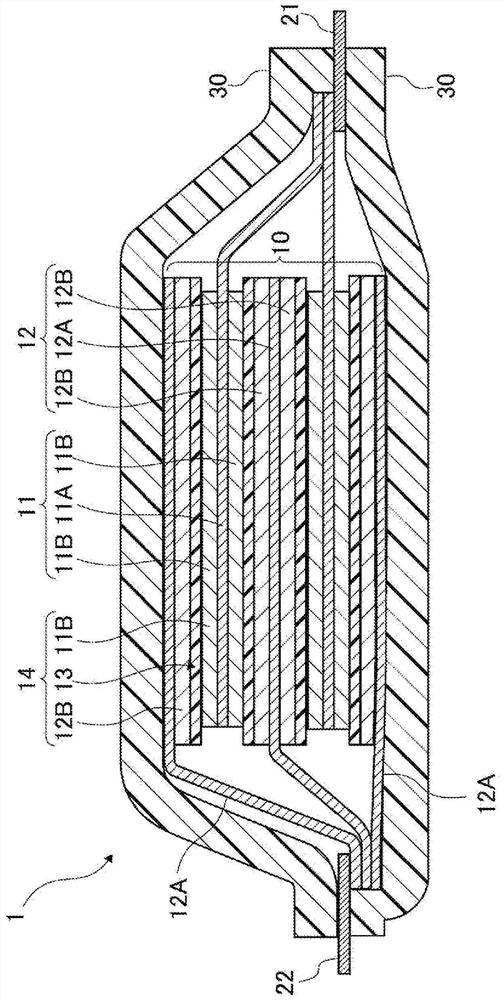

Negative electrode containing microcapsules, and lithium-ion secondary battery equipped with same

A secondary battery, lithium ion technology, applied in secondary batteries, negative electrodes, battery electrodes, etc., to achieve the effect of suppressing short-circuit current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

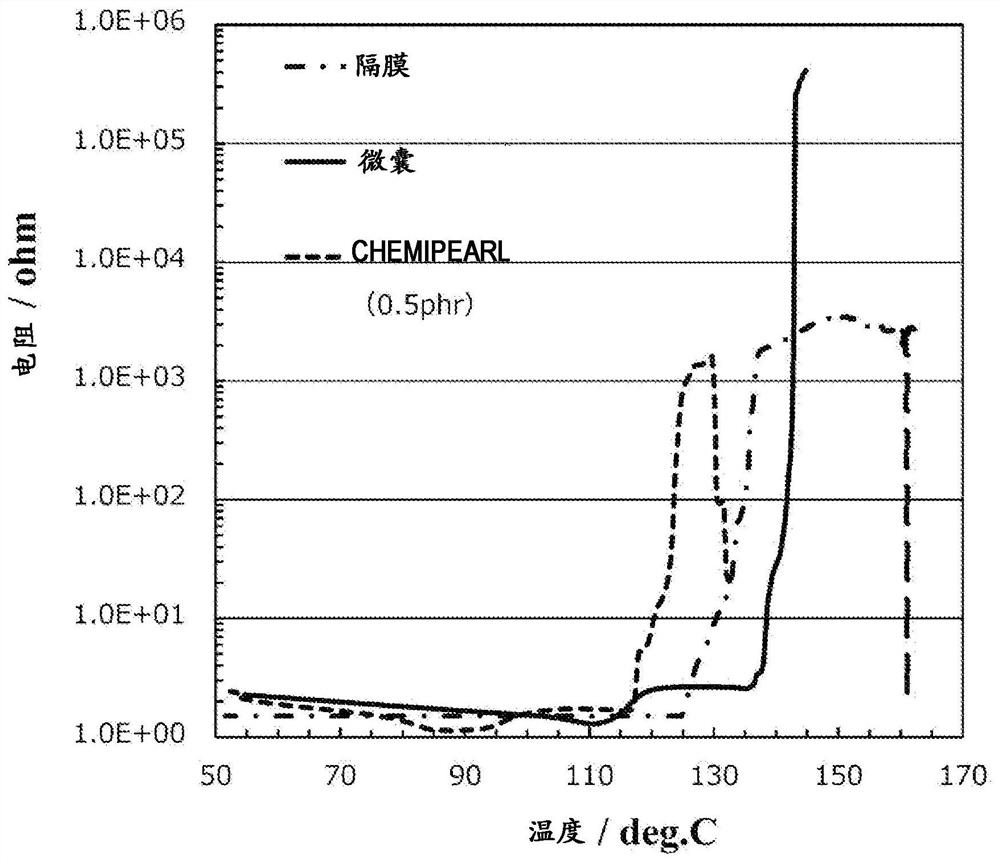

Embodiment 1

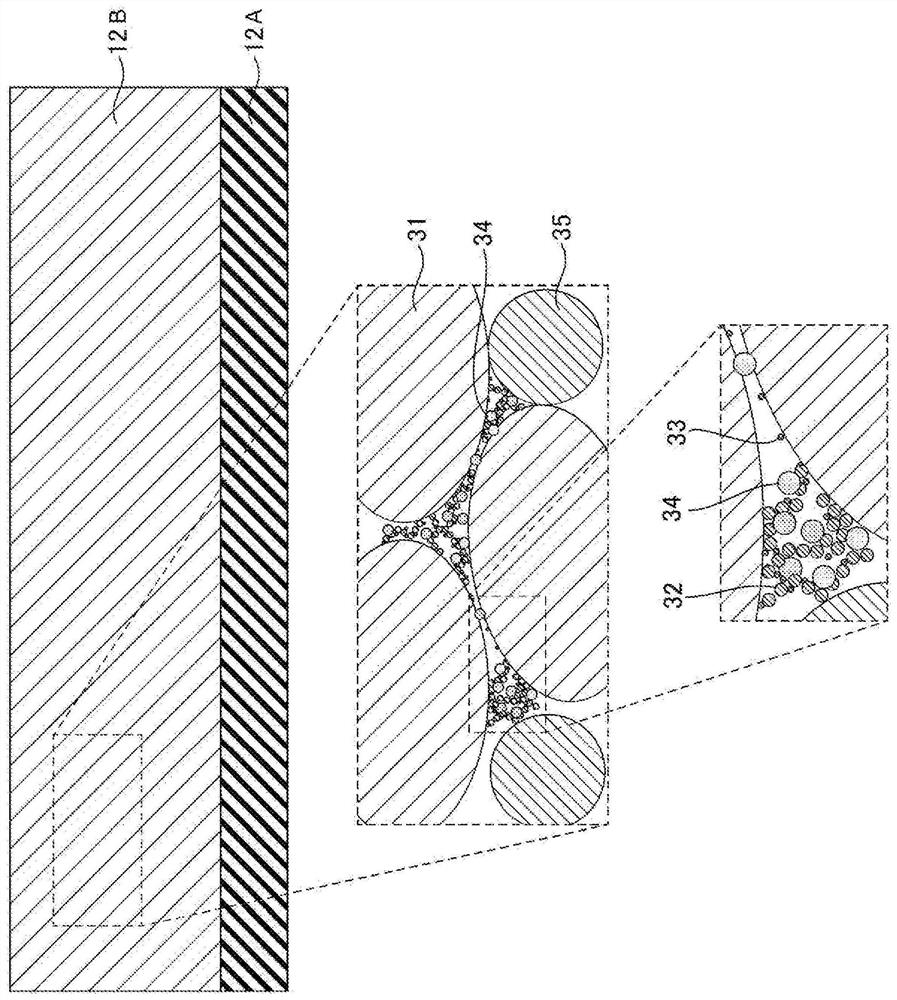

[0090] -Negative electrode production-

[0091] 1. Slurry Preparation

[0092] A 5 L planetary disperser was used for slurry preparation.

[0093] With natural graphite 960g, Super-P (conductive carbon, BET specific surface area is 62m 2 / g) 10g, microcapsules (FS-100SD manufactured by Matsumoto Yushi Pharmaceutical Co., Ltd., expansion start temperature is 125 to 135°C, maximum expansion temperature is 150 to 160°C) 5g were mixed for 5 minutes, then, 1% CMC (using pure CMC was dissolved in water) 450 g, and further mixed for 30 minutes. Next, 300 g of a 1%-CMC aqueous solution was added and kneaded for 30 minutes, and then 250 g of 1%-CMC was further added and kneaded for 30 minutes. Then, 25 g of SBR (40% emulsion) used as a binder and 12.5 g of polymer particles (manufactured by Mitsui Chemicals, Inc., CHEMIPEARL (registered trademark) W4005, softening point of 110° C., 40% emulsion) were added to carry out Mix for 30 minutes, then vacuum defoam for 30 minutes. In the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com