Building gypsum based on industrial solid waste desulfurized gypsum as raw material and preparation method thereof

A technology for desulfurized gypsum and industrial solid waste, applied in the field of building materials, can solve the problems of large surface area and particle distribution, high water content of desulfurized gypsum, and large volumetric weight of gypsum products, and achieve uniform dehydration, good heat preservation effect, and increased water retention and adhesive properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

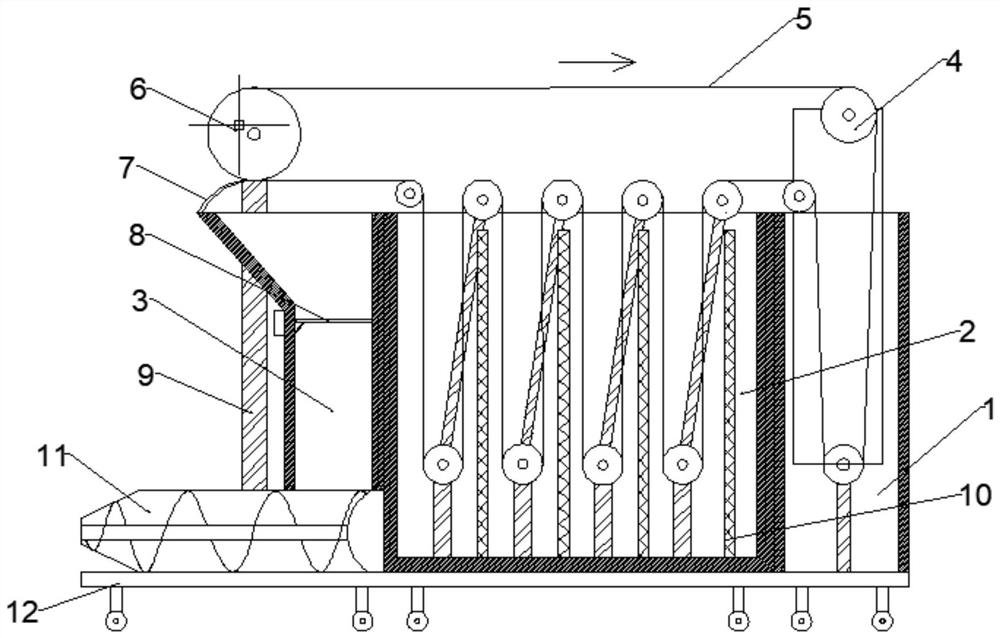

Method used

Image

Examples

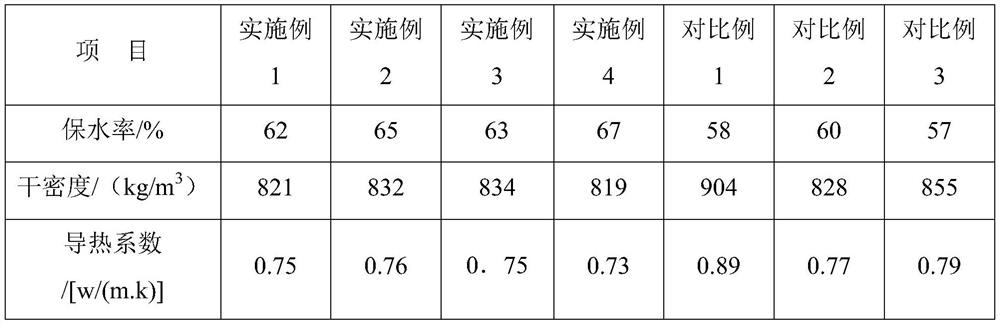

Embodiment 1

[0030] A kind of building gypsum based on industrial solid waste desulfurization gypsum as raw material, including the following raw materials in parts by weight:

[0031] 120 parts of desulfurized gypsum, 30 parts of microporous ceramics, 40 parts of vitrified microbeads, 20 parts of expanded perlite, 5 parts of coconut shell powder, 3 parts of cement, 1 part of methyl cellulose, 0.3 parts of retarder, methylol 0.2 part of base cellulose, 0.2 part of polypropylene fiber, 0.2 part of composite early strength agent; wherein, the retarder is dextrin; the composite early strength agent is anhydrous sodium sulfate, ferrous ammonium sulfate and triethanolamine according to Obtained by mixing in a weight ratio of 10:6:1;

[0032] The above-mentioned preparation method of building gypsum based on industrial solid waste desulfurization gypsum as raw material comprises the following steps:

[0033] S1, pretreatment, the desulfurization gypsum is subjected to dehydration pretreatment, ...

Embodiment 2

[0037] A kind of building gypsum based on industrial solid waste desulfurization gypsum as raw material, including the following raw materials in parts by weight:

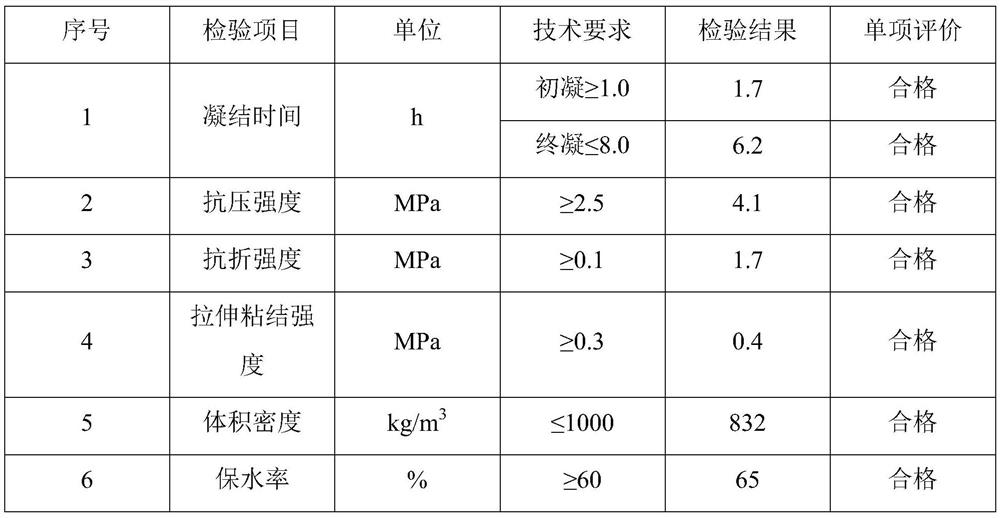

[0038] 140 parts of desulfurized gypsum, 35 parts of microporous ceramics, 55 parts of vitrified microbeads, 24 parts of expanded perlite, 6 parts of coconut shell powder, 7 parts of cement, 2 parts of methyl cellulose, 0.32 parts of retarder, methylol 0.3 part of base cellulose, 0.3 part of polypropylene fiber, 0.3 part of composite early strength agent; the retarder is SG-12 (Suzhou Xingbang Chemical Building Materials Co., Ltd); the composite early strength agent is anhydrous sodium sulfate , alum and triethanolamine are obtained by mixing according to the weight ratio of 10:4:1;

[0039] The above-mentioned preparation method of building gypsum based on industrial solid waste desulfurization gypsum as raw material comprises the following steps:

[0040] S1, pretreatment, the desulfurization gypsum is subjected...

Embodiment 3

[0044] A kind of building gypsum based on industrial solid waste desulfurization gypsum as raw material, including the following raw materials in parts by weight:

[0045] 160 parts of desulfurized gypsum, 45 parts of microporous ceramics, 60 parts of vitrified microbeads, 35 parts of expanded perlite, 8 parts of coconut shell powder, 8 parts of cement, 3 parts of methyl cellulose, 0.35 parts of retarder, methylol 0.4 part of base cellulose, 0.4 part of polypropylene fiber, 0.5 part of composite early strength agent; the retarder is SG-12 (Suzhou Xingbang Chemical Building Materials Co., Ltd); the composite early strength agent is anhydrous sodium sulfate , alum and triethanolamine are obtained by mixing according to the weight ratio of 10:4:1;

[0046] A method for preparing building gypsum based on industrial solid waste desulfurized gypsum as raw material, comprising the following steps:

[0047]S1, pretreatment, the desulfurization gypsum is subjected to dehydration pretr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com