Lithium-ion battery composite positive electrode material and preparation method thereof

A technology of lithium ion battery and positive electrode material, applied in the field of composite positive electrode material of lithium ion battery and its preparation, can solve problems such as poor cycle and safety performance, and achieve the effects of improving stability, improving storage and processing performance, and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) The commercially available Ni 0.88 Co 0.09 Al 0.03 (OH) 2 The precursor and lithium hydroxide are thoroughly mixed, and the molar ratio of Li:(Ni+Co+Al) is 1.02:1. Raise the mixed powder to 750°C at 2°C / min in a pure oxygen atmosphere and keep it for 20h to obtain the base material LiNi 0.88 Co 0.09 Al 0.03 O 2 , Marked as A.

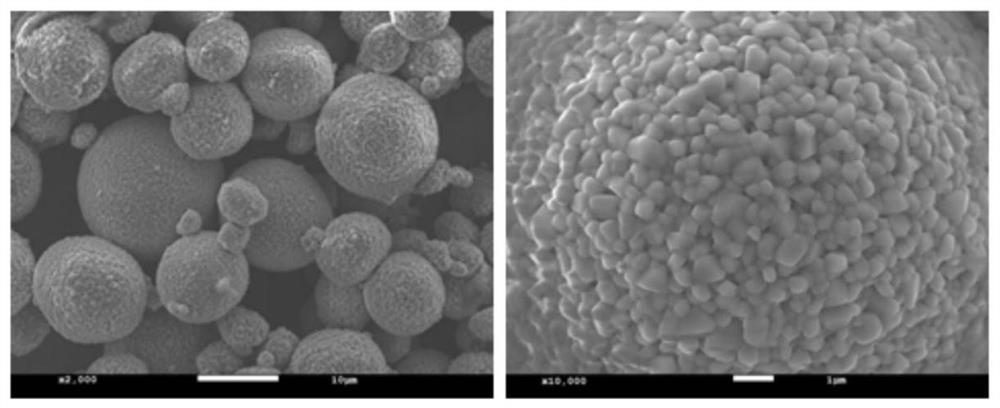

[0040] (2) Weigh 500 grams of LiNi 0.88 Co 0.09 Al 0.03 O 2 And 2.5 grams of alumina with an average particle size of 20nm, put them into a mechanical fusion machine for fusion, adjust the rotation speed to 3000rpm for 5 minutes, and raise the collected sample to 500°C at 2°C / min in a pure oxygen atmosphere. Insulate for 5h to obtain the first coating layer of LiNi 0.88 Co 0.09 Al 0.03 O 2 .

[0041] (3) Weigh 500 grams of the above sample and 50 grams of lithium iron manganese phosphate with an average primary particle size of 80 nm, and perform mechanical fusion at 4500 rpm for 3 minutes to obtain a sample of the second coating layer, which is t...

Embodiment 2

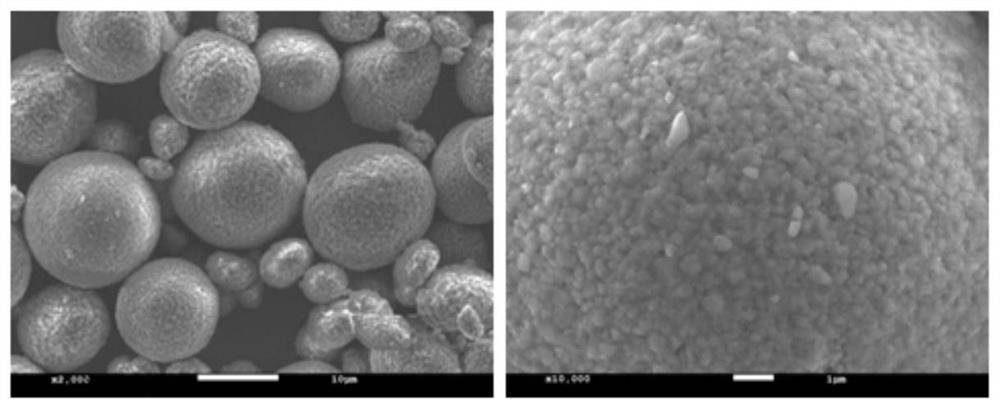

[0057] Will Ni 0.5 Co 0.2 Mn 0.3 (OH) 2 The precursor and lithium carbonate are thoroughly mixed, and the molar ratio of Li:(Ni+Co+Mn) is 1.08:1. Raise the mixed powder to 950°C at 2°C / min in an air atmosphere and keep it for 6 hours to obtain the base material LiNi 0.5 Co 0.2 Mn 0.3 O 2 .

[0058] Weigh 500 grams of LiNi 0.5 Co 0.2 Mn 0.3 O 2 And 15 grams of lithium metaphosphate with an average particle size of 100nm, put them into a mechanical fusion machine for fusion, adjust the speed to 3500rpm, for 5 minutes, and raise the collected sample to 800°C at 2°C / min in an air atmosphere. Keep holding for 2h to get the first coating layer of LiNi 0.5 Co 0.2 Mn 0.3 O 2 . Weigh 500 grams of the above sample and 10 grams of lithium iron manganese phosphate with an average primary particle size of 150 nm, and perform mechanical fusion at a rotation speed of 2000 rpm for 10 minutes to obtain a sample of the second coating layer, that is, the final composite positive electrode material....

Embodiment 3

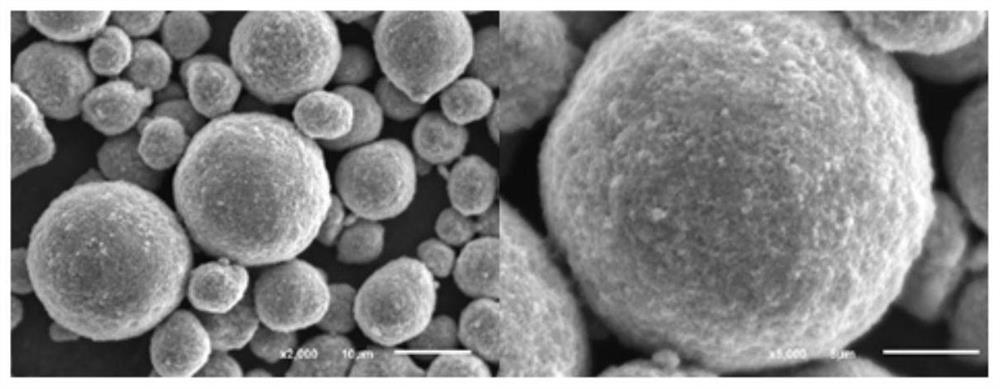

[0060] Will Ni 0.98 Co 0.01 Mn 0.005 Al 0.005 CO 3 The precursor and lithium hydroxide are thoroughly mixed, and the molar ratio of Li:(Ni+Co+Mn+Al) is 1.01:1. Raise the mixed powder to 720°C at 2°C / min in a pure oxygen atmosphere and keep it for 12h to obtain the base material LiNi 0.98 Co 0.01 Mn 0.005 Al 0.005 O 2 .

[0061] Weigh 500 grams of LiNi 0.98 Co 0.01 Mn 0.005 Al 0.005 O 2 And 2.5 grams of tungsten oxide with an average particle size of 10nm and 2.5 grams of yttrium metaphosphate with an average particle size of 50nm, put them into a mechanical fusion machine for fusion, adjust the rotation speed to 2000rpm, the time is 8 minutes, and put the collected samples in pure oxygen Raise the temperature to 300°C at 1°C / min under the atmosphere and keep it for 10h to obtain the first coating layer of LiNi 0.98 Co 0.01 Mn 0.005 Al 0.005 O 2 . Weigh 500 grams of the above sample and 150 grams of lithium iron manganese phosphate with an average primary particle size of 30 nm, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com