Method of preparing products made of dough having a filling of byproducts.

A production method and dough technology, which is applied in dough preparation, pre-baked dough processing, food science, etc., can solve the problems of complex fish filling process, insufficient dietary characteristics, and loss of beneficial food characteristics, etc., to improve functional value , Improve the attractiveness of the product and improve the food value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

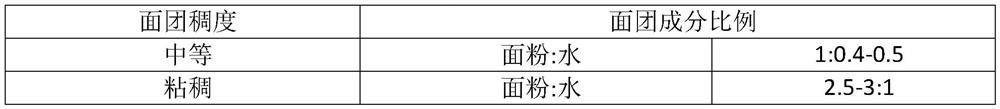

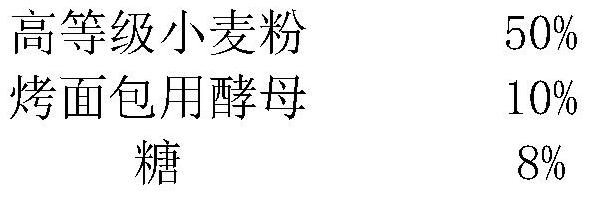

Method used

Image

Examples

example 2

[0058] Example 2. Processing and making dough and stuffing, noodle product forming, cooked frying, etc. are the same as Example 1. The difference is that this example filling contains poultry offal. Chicken and goose are prepared according to the following weight ratios: stomach 40%, liver 30%, heart 30%.

example 3

[0059] Example 3. Processing and making dough and stuffing, noodle product forming, cooked frying, etc. are the same as Example 1. The difference is that the cooked frying oil in this example includes high-grade mutton and vegetable oil, the latter accounting for 40% by weight.

[0060] The use of high-grade sheep oil can add important dietary substances to finished products: saturated and unsaturated fatty acids, such as stearic acid, palmitic acid, myristic acid, capric acid, butyric acid, lauric acid, etc.; mineral compounds, such as sodium, magnesium, Copper, zinc, selenium, etc.; vitamins A, B1 and E. In addition, sheep oil is also rich in natural lanolin.

example 4

[0061] Example 4. Processing and making of dough and stuffing, and shaping of noodle products. The shaped products are frozen in a food factory, and packed into airtight food packaging boxes, 6-10 per box (the weight of each box is the same as the finished product). Then it can be sent to the hotel, and the storage period is 24 hours.

[0062] Thaw frozen foods slowly before deep frying.

[0063] Then fry as in Example 1.

[0064] The important dietary substances of livestock animal offal can refer to the monograph "Russian Food Chemical Composition", DeLiprint Press, Moscow, 2002; and the monograph "Endocrine-Enzyme and Special Raw Material Animal Offal Production Technology ", Light Industry and Food Industry Publishing House, Moscow, 1982.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com