Lyophyllum decastes industrialized cultivation method

A cultivation method and technology of pilose antler mushrooms, applied in the field of fungi production, can solve the problems of weak mushroom growth, slow mycelium germination, and long post-ripening time, and achieve low shrinkage rate, thorough sterilization, and short post-ripening time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

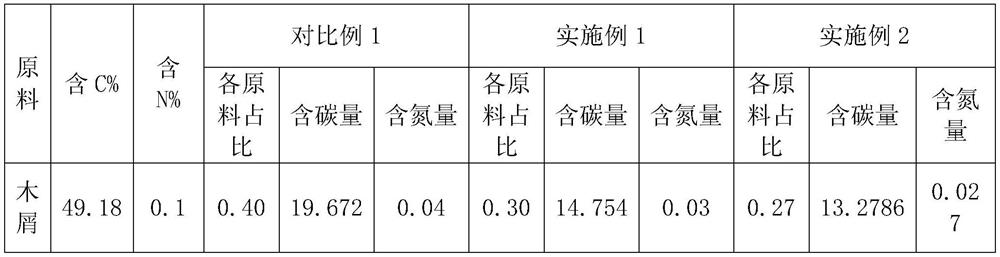

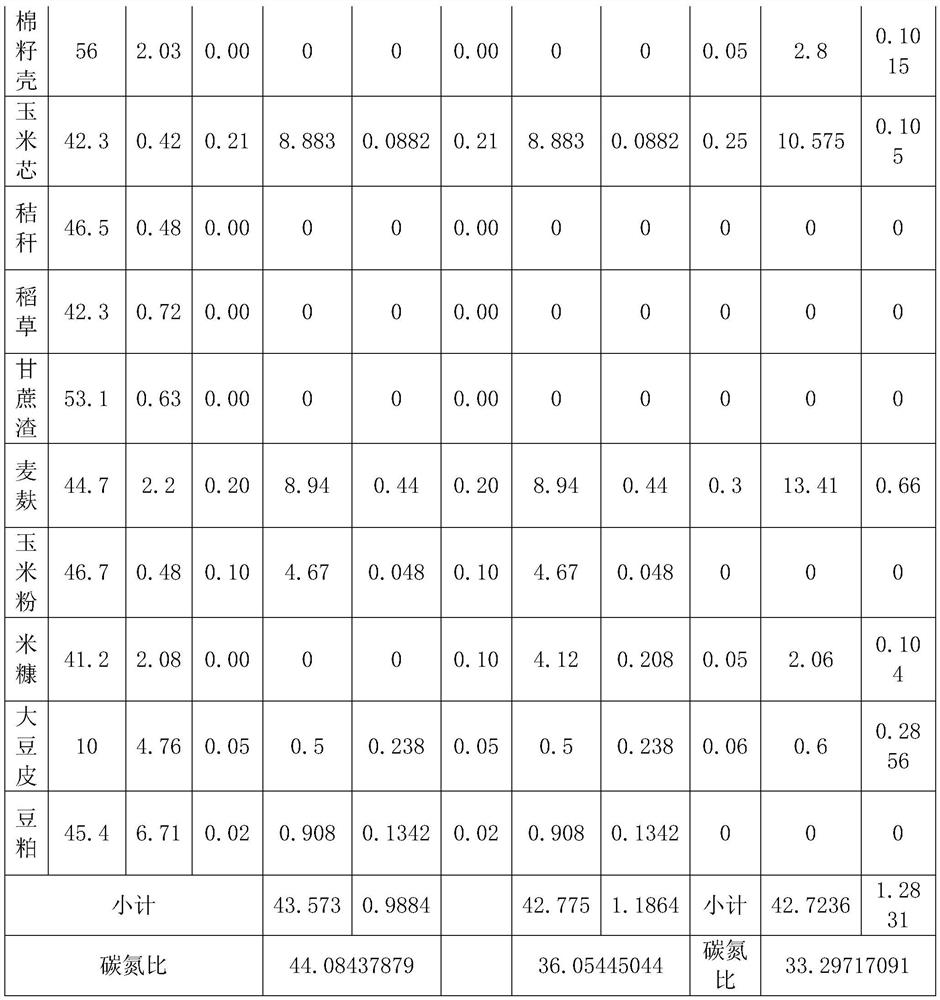

Embodiment 1

[0035] The matrix, in terms of mass percentage, includes the following raw materials: 30% wood chips, 21% corn cobs, 20% wheat bran, 10% corn flour, 5% soybean hulls, 2% soybean meal, 10% rice bran, 1% light calcium carbonate, Slaked lime 1%.

[0036] A factory cultivation method of pilose antler mushroom, comprising the following steps:

[0037] 1) Stirring: according to the mass ratio, dry and stir the above matrix for 25 minutes, then add water and stir for 45 minutes;

[0038] After wet stirring, the water content of the matrix is controlled at 66%, and the Ph value is controlled at 7.5;

[0039] 2) bottling: carry out bottling process to the substrate in step 1);

[0040] 3) High-pressure steam sterilization: use high-pressure steam to sterilize after bottling;

[0041] Sterilization time: heat up to 100°C, keep warm for 60 minutes, then keep warm at 115°C for 20 minutes, and finally keep warm at 122°C for 70 minutes, pressure 0.013 MPa;

[0042] 4) Cooling: After s...

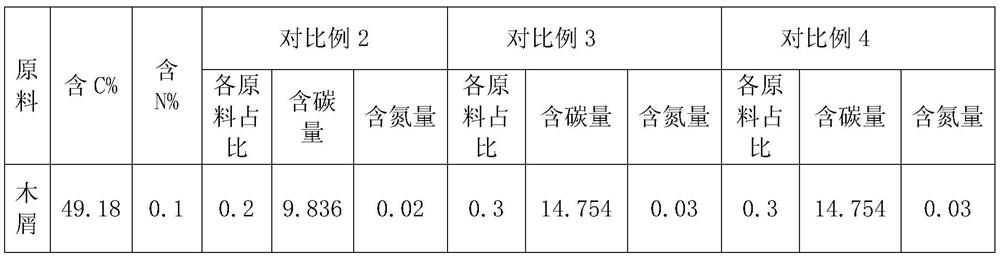

Embodiment 2

[0059] The matrix, in terms of mass percentage, includes the following raw materials: 27% corncob, 5% cottonseed hull, 25% sawdust, 30% wheat bran, 5% rice bran, 6% soybean hull, 1.0% light calcium carbonate, and 1.0% slaked lime.

[0060] A factory cultivation method of pilose antler mushroom, comprising the following steps:

[0061] 1) Stirring: according to the mass ratio, dry and stir the above matrix for 25 minutes, then add water and stir for 45 minutes;

[0062]After wet stirring, the water content of the matrix is controlled at 66%, and the Ph value is controlled at 7.5;

[0063] 2) bottling: carry out bottling process to the substrate in step 1);

[0064] 3) High-pressure steam sterilization: use high-pressure steam to sterilize after bottling;

[0065] Sterilization time: heat up to 100°C, keep warm for 60 minutes, then keep warm at 115°C for 20 minutes, and finally keep warm at 122°C for 70 minutes, pressure 0.013 MPa;

[0066] Cooling: After sterilization, put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com