Non-supported catalyst and preparation method of chlorotrifluoroethylene or trifluoroethylene

A catalyst and non-supported technology, applied in the direction of catalyst activation/preparation, dehydrohalogenation preparation, chemical instruments and methods, etc., can solve the problems of expensive catalysts, low conversion rate of raw materials, increased production costs, etc., and achieve high low-temperature activity , High temperature anti-sintering ability, low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

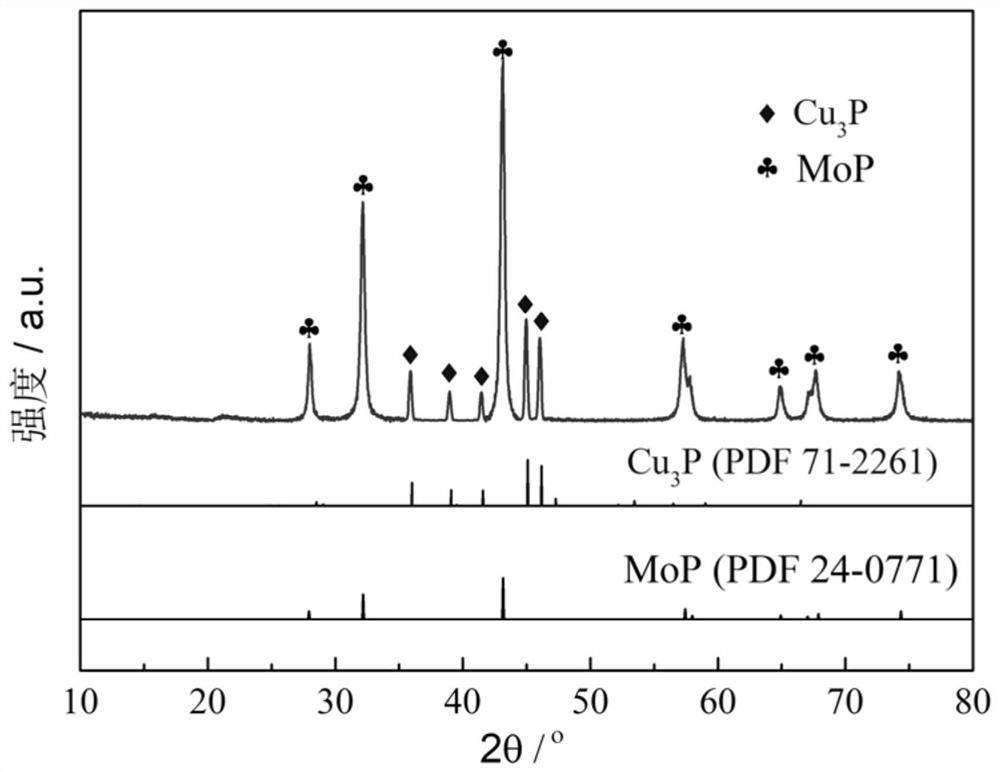

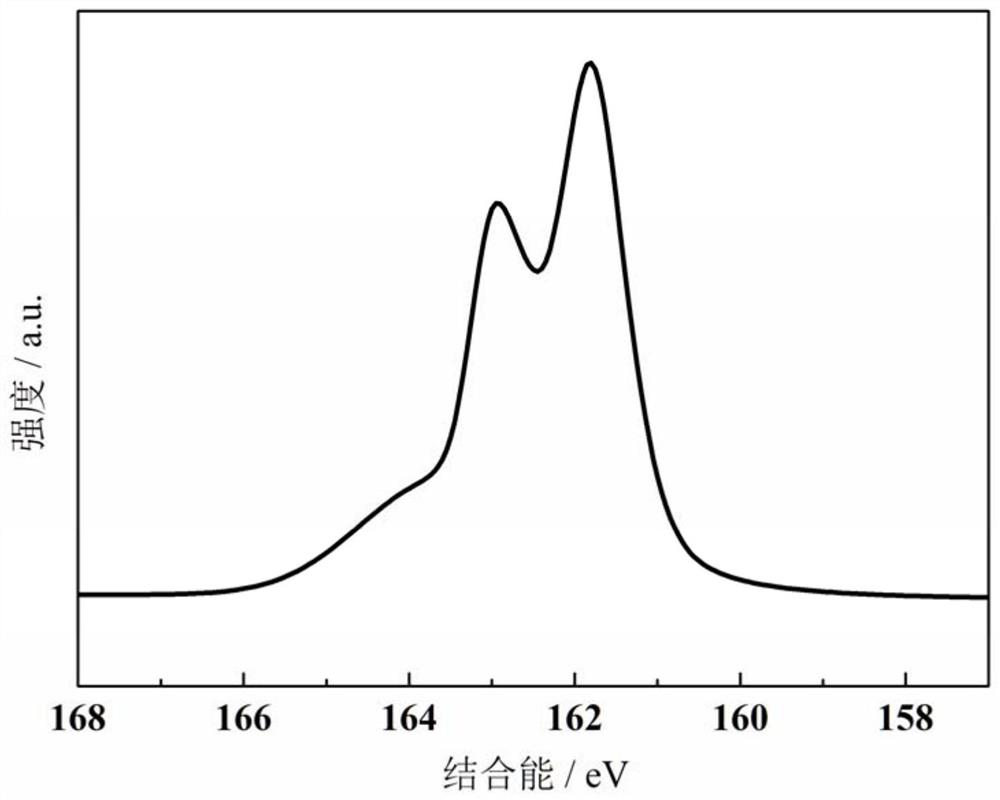

[0046] This embodiment provides a kind of non-supported catalyst, described non-supported catalyst comprises sulfur-containing bulk phase MoP, and auxiliary agent is copper chloride;

[0047]In the sulfur-containing bulk MoP, MoP is a molybdenum phosphide covalent compound with a crystal structure formed by combining metallic molybdenum and non-metallic phosphorus, and the molar ratio of molybdenum to phosphorus is 1;

[0048] In the sulfur-containing bulk MoP, the molar ratio of molybdenum to sulfur is 0.5;

[0049] The molar ratio of additive metal copper to molybdenum is 0.7.

[0050] The preparation method of the non-supported catalyst of the present embodiment, the preparation method specifically includes the following steps:

[0051] Step 1, ammonium sulfide and phosphorus trichloride reaction preparation (NH 4 ) 4 P 2 S 6 ;

[0052] The concrete process of step one is: according to (NH 4 ) 2 S and phosphorus trichloride molar ratio is 2 weighing ratio (NH 4 ) ...

Embodiment 2

[0071] The present embodiment provides a kind of non-supported catalyst, described non-supported catalyst comprises sulfur-containing bulk phase MoP, and auxiliary agent is palladium chloride;

[0072] In the sulfur-containing bulk MoP, MoP is a molybdenum phosphide covalent compound with a crystal structure formed by the combination of metallic molybdenum and non-metallic phosphorus, and the molar ratio of molybdenum to phosphorus is 0.3;

[0073] In the sulfur-containing bulk MoP, the molar ratio of molybdenum to sulfur is 1;

[0074] The molar ratio of the auxiliary metal palladium to molybdenum is 0.01.

[0075] The preparation method of the non-supported catalyst of the present embodiment, the preparation method specifically includes the following steps:

[0076] Step 1, ammonium sulfide and phosphorus trichloride reaction preparation (NH 4 ) 4 P 2 S 6 ;

[0077] The concrete process of step one is: according to (NH 4 ) 2 The metering ratio of S to phosphorus tric...

Embodiment 3

[0096] This embodiment provides a kind of non-supported catalyst, described non-supported catalyst comprises sulfur-containing bulk phase MoP, and auxiliary agent is chloroplatinic acid;

[0097] In the sulfur-containing bulk phase MoP, MoP is a molybdenum phosphide covalent compound with a crystal structure formed by the combination of metallic molybdenum and non-metallic phosphorus, and the molar ratio of molybdenum to phosphorus is 3;

[0098] In the sulfur-containing bulk MoP, the molar ratio of molybdenum to sulfur is 2.7;

[0099] The molar ratio of the auxiliary metal platinum to molybdenum is 0.3.

[0100] The preparation method of the non-supported catalyst of the present embodiment, the preparation method specifically includes the following steps:

[0101] Step 1, ammonium sulfide and phosphorus trichloride reaction preparation (NH 4 ) 4 P 2 S 6 ;

[0102] The concrete process of step one is: according to (NH 4 ) 2 The metering ratio of S and phosphorus trich...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com