Method for recycling and dehydrating hydrocarbon substances in oil sludge dissolved by liquid dimethyl ether

A dimethyl ether, liquid technology, applied in the field of resources and environment, can solve the problems of high toxicity, environmental pollution recovery cost, difficult to effectively guarantee the operation safety, etc., and achieve the effect of high separation efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

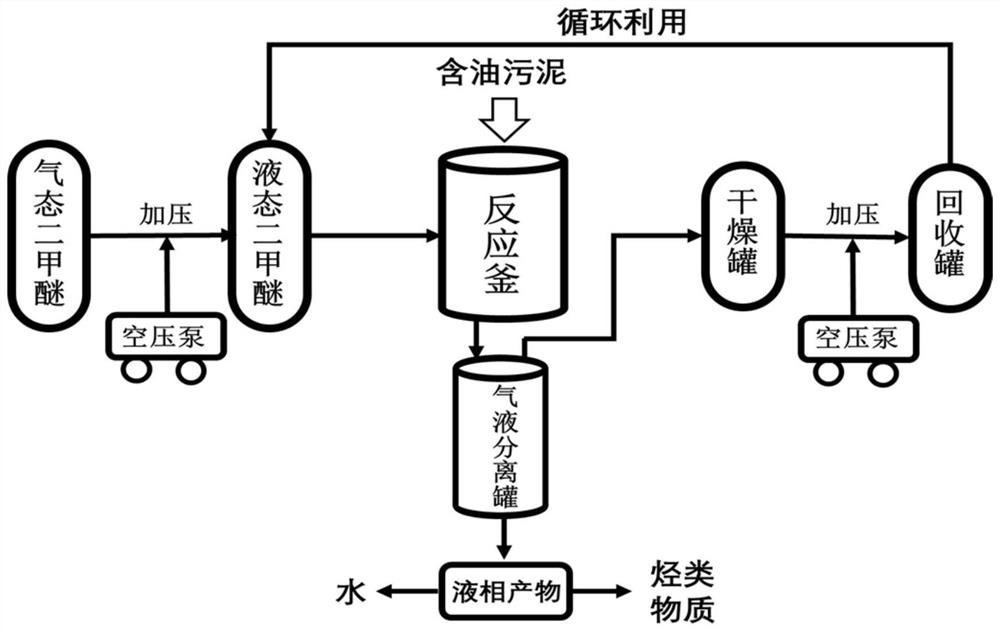

[0029] figure 1 It is a process flow diagram of the present invention. like figure 1 Shown, the method for recovering and dehydrating hydrocarbons in liquid dimethyl ether dissolved oil sludge, the steps are as follows:

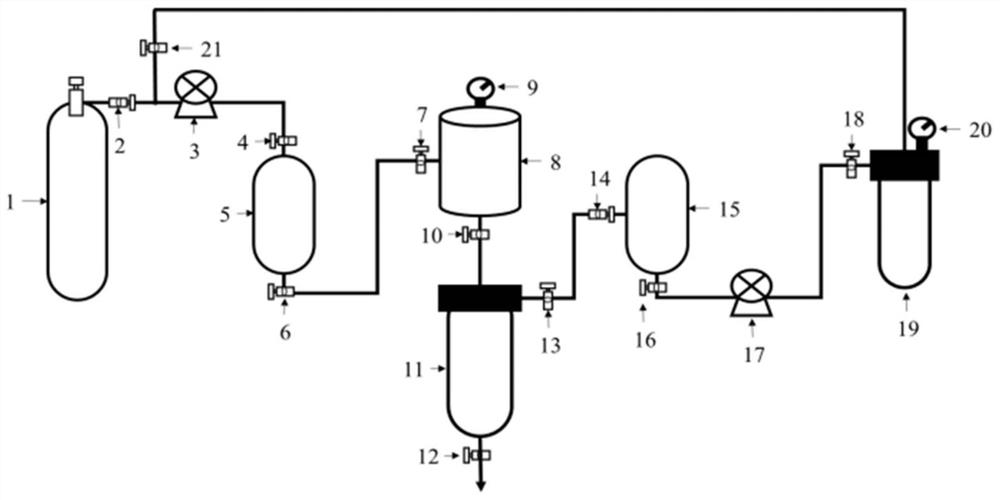

[0030] Step 1: Put the oil sludge in the reaction kettle 8, pressurize and liquefy the gas dimethyl ether in the gas tank 1 in the temporary storage tank 5 by the air pump 3 and convert it into a liquid state, and then inject it into the reaction kettle 8 to mix with the oil sludge dissolve. The amount of liquid dimethyl ether is 10-40 times the mass of sludge, the reaction pressure is 0.5-2MPa, the reaction temperature is 20-60°C, the reaction time is 20-40min, the stirring rate is 60rpm-120rpm / min, and the stirring time is 20-40min.

[0031] Step 2: After the liquid dimethyl ether and the oil sludge are fully mixed and reacted, the pressure is reduced by adjusting the pressure reducing valve on the reactor 8, and the product is subjected to solid-liquid ...

Embodiment 2

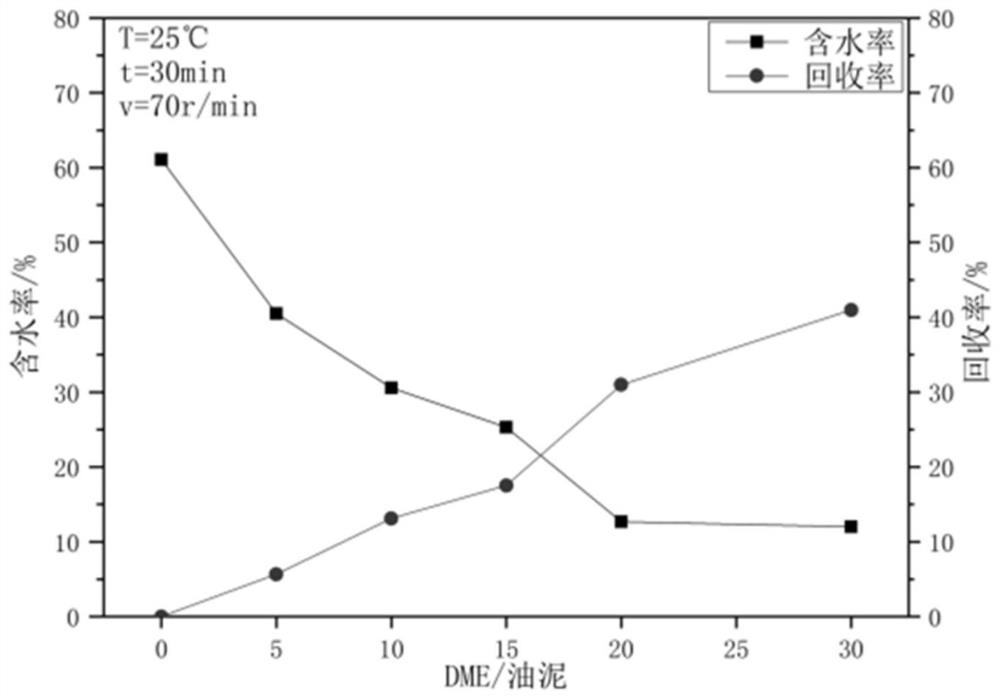

[0037] A single factor investigation was carried out on the reaction conditions affecting the results, the results are shown in Figure 3-6 shown.

[0038] image 3 It is the effect diagram of mass ratio on water content and oil recovery rate. It can be seen that the mass ratio of liquid dimethyl ether to oil sludge has a great influence on recovery rate and water content after oil sludge treatment. With the increase of mass ratio, oil sludge treatment After the water content drops rapidly, when the mass ratio is 20, it basically tends to be stable. At this time, the water content of the oil sludge is between 10-15%, and the oil recovery rate increases with the increase of the mass ratio.

[0039] Figure 4 is the effect diagram of reaction temperature on water content and oil recovery rate; it can be seen that reaction temperature has a great influence on recovery rate and water content of oil sludge after treatment. When the temperature is 60°C, the moisture content of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com