High-strength fiber reinforced foamed cement insulation board and preparation method thereof

A technology of foamed cement and high-strength fibers, which is applied in the field of foamed cement boards, can solve the problems of reducing the strength and durability of foamed cement insulation boards, the decline in mechanical properties and strength, and the reduction of thermal conductivity of boards, etc., to achieve good appearance quality, Long service life and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

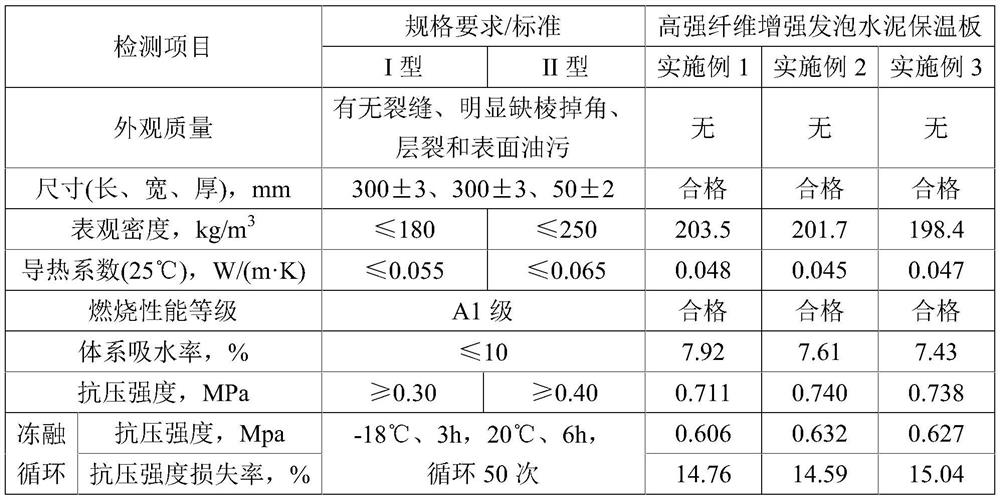

Examples

Embodiment 1

[0035] The high-strength fiber-reinforced foamed cement insulation board of this embodiment is made of water and the following raw materials in parts by weight: 95 parts of ordinary Portland cement, 5.0 parts of silica fume, 0.50 parts of water reducing agent, 6.0 parts of foaming agent hydrogen peroxide, 1.8 parts of calcium stearate, 0.6 parts of coagulant lithium carbonate, 6.5 parts of microcrystalline foam glass slag, 8.0 parts of styrene-acrylic emulsion, 0.50 parts of polypropylene fiber; the water-binder ratio is 0.55.

[0036] The preparation method of the high-strength fiber-reinforced foamed cement insulation board of this embodiment comprises the following steps:

[0037] 1) Take the microcrystalline foam glass slag of the recipe amount, spray water on the surface of the microcrystalline foam glass slag, the water consumption is 8% of the weight of the microcrystalline foam glass slag, stir to make the particle surface evenly wet, add the microcrystalline foam glass...

Embodiment 2

[0041] The high-strength fiber-reinforced foamed cement insulation board of this embodiment is made of water and the following raw materials in parts by weight: 95.5 parts of ordinary Portland cement, 4.5 parts of silica fume, 0.55 parts of water reducing agent, 6.5 parts of foaming agent hydrogen peroxide, 1.9 parts of calcium stearate, 0.55 parts of coagulant lithium carbonate, 6.0 parts of microcrystalline foam glass slag, 7.5 parts of styrene-acrylic emulsion, 0.55 parts of polypropylene fiber; the water-binder ratio is 0.55.

[0042] The preparation method of the high-strength fiber-reinforced foamed cement insulation board of this embodiment comprises the following steps:

[0043] 1) Take the microcrystalline foam glass slag of the formula, spray water on the surface of the microcrystalline foam glass slag, the water consumption is 9% of the weight of the microcrystalline foam glass slag, stir to make the surface of the particles evenly wet, add the microcrystalline foam ...

Embodiment 3

[0047] The high-strength fiber-reinforced foamed cement insulation board of this embodiment is made of water and the following raw materials in parts by weight: 96 parts of ordinary Portland cement, 4.0 parts of silica fume, 0.60 parts of water reducing agent, 7.0 parts of foaming agent hydrogen peroxide, 2.0 parts of calcium stearate, 0.6 parts of coagulant lithium carbonate, 5.5 parts of microcrystalline foam glass slag, 7.0 parts of styrene-acrylic emulsion, 0.60 parts of polypropylene fiber; the water-binder ratio is 0.55.

[0048] The preparation method of the high-strength fiber-reinforced foamed cement insulation board of this embodiment comprises the following steps:

[0049] 1) Take the microcrystalline foam glass slag of the formula, spray water on the surface of the microcrystalline foam glass slag, the water consumption is 10% of the weight of the microcrystalline foam glass slag, stir to make the surface of the particles evenly wet, add the microcrystalline foam gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com