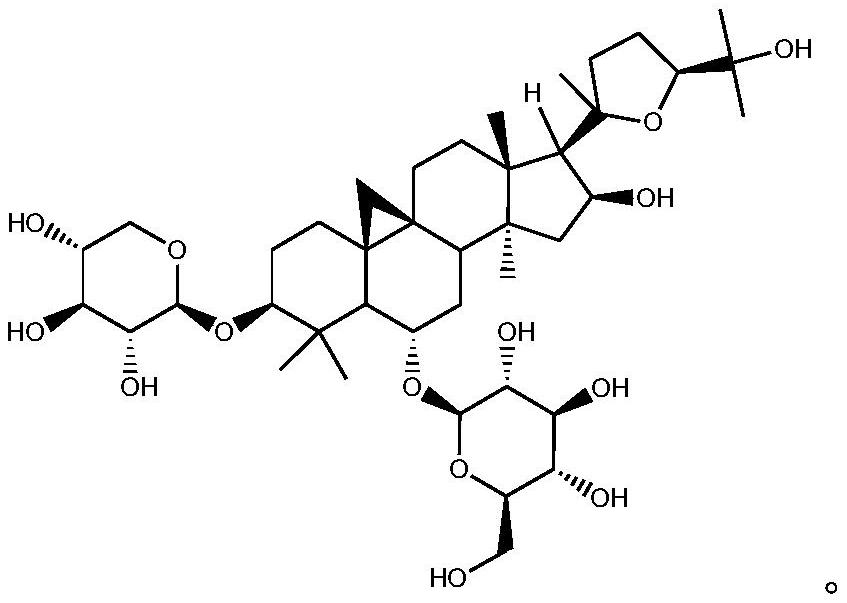

Method for extracting astragaloside from fresh astragalus membranaceus

A technology for astragaloside IV and astragalus, which is applied in the field of extracting astragaloside IV, can solve the problems affecting the extraction of astragaloside IV, pollution of macroporous adsorption resin, increase production cost, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

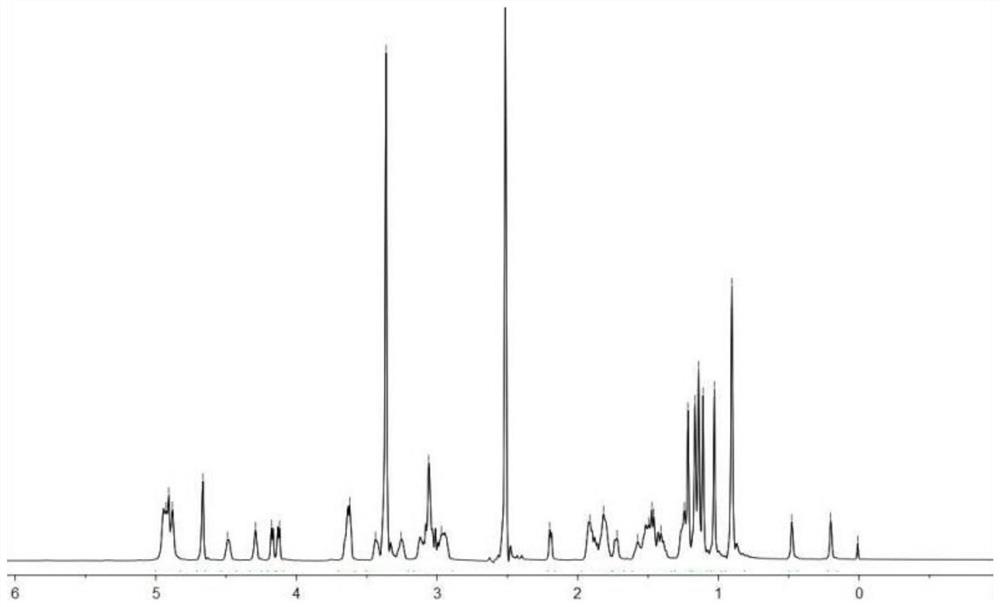

[0021] In a 5L ultrasonic extraction device, put 1Kg of fresh astragalus roots that have been cleaned and cut into sections, add 5.0L of 80% ethanol solution, adjust the ultrasonic power to 350W, extract at a temperature of 55°C, extract for 40 minutes, extract 3 times, and combine the extracts , Remove ethanol under reduced pressure to obtain a concentrated solution; add 2.0 L of water to the concentrated solution to make a concentrated solution, and filter. Add sodium hydroxide-calcium hydroxide (mass ratio 1:8) mixed alkali to the filtrate, adjust the pH to 13, stir at 45°C for 3.5 hours, let it stand, and filter through a 250-mesh filter; adjust the pH value of the filtrate to 5,40 with dilute hydrochloric acid Under stirring at ℃, add 0.6L chitosan solution to the filtrate, let it stand, and filter with a 500-mesh stainless steel filter. The filtrate was adsorbed with AB-8 macroporous adsorption resin column, eluted with 80% ethanol solution, the eluate was concentrated t...

Embodiment 2

[0023] In a 5L ultrasonic extraction device, put 1Kg of fresh astragalus roots cleaned and cut into sections, add 6.0L of 75% ethanol solution, adjust the ultrasonic power to 300W, extract at 60°C for 60 minutes, extract 3 times, and combine the extracts , Remove ethanol under reduced pressure to obtain a concentrated solution, add 0.5 L of water to the concentrated solution to make a concentrated solution, and filter. Add sodium hydroxide-calcium hydroxide (mass ratio 1:8) mixed alkali to the filtrate, adjust the pH to 13, stir at 50°C for 4 hours, let it stand, and filter through a 200-mesh filter; adjust the pH value of the filtrate to 6 with hydrochloric acid, 45°C Under stirring, add 0.8L chitosan solution in the filtrate, let it stand, and filter with a 500-mesh stainless steel strainer. The filtrate was adsorbed with a D101 macroporous adsorption resin column, eluted with 80% ethanol solution, the eluate was concentrated to a small volume, a precipitate appeared after s...

Embodiment 3

[0025] In a 5L ultrasonic extraction device, put 1Kg of fresh Astragalus roots cleaned and cut into sections, add 8L of 85% ethanol solution, adjust the ultrasonic power to 350W, extract the temperature at 55°C, extract for 40 minutes, extract 3 times, and combine the extracts. Ethanol was removed under reduced pressure to obtain a concentrated solution; 1.5 L of water was added to the concentrated solution to prepare a concentrated solution, which was filtered. Add sodium hydroxide-calcium hydroxide (mass ratio 1:6) mixed alkali to the filtrate, adjust the pH to about 12, stir at 40°C for 4 hours, let it stand, and filter through a 200-mesh filter; adjust the pH value of the filtrate to 5,40 with hydrochloric acid Under stirring at ℃, add 1.0L chitosan solution to the filtrate, let it stand, and filter with a 300-mesh stainless steel filter. The filtrate was adsorbed with HPD-100 macroporous adsorption resin column, eluted with 80% ethanol solution, the eluate was concentrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com