Preparation method of boehmite slurry for lithium ion battery

A lithium-ion battery and boehmite technology, which is applied in secondary batteries, circuits, electrical components, etc., can solve the failure of polymer bonding properties, which cannot meet the needs of rapid manufacturing and thermal stability of boehmite coating layers at the same time Poor performance and other problems, to avoid the effect of high-speed shearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

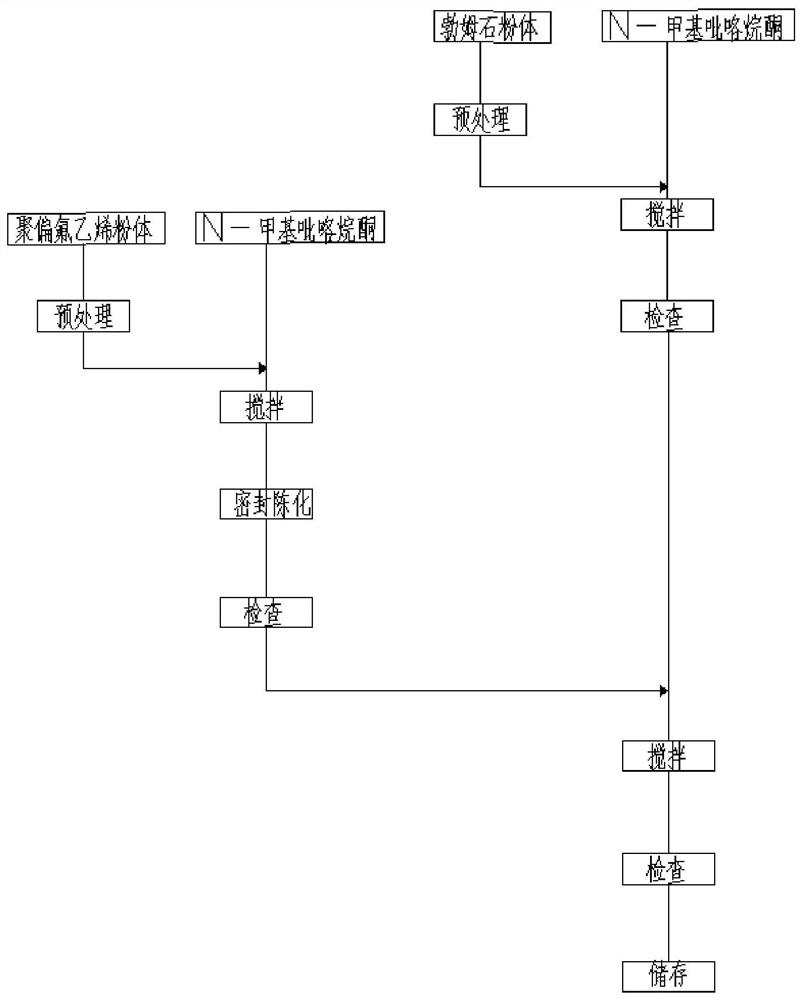

[0044] A preparation method of boehmite slurry for lithium ion battery, comprising the steps of:

[0045] (1) Dissolve polyvinylidene fluoride powder (PVDF9700) in N-methylpyrrolidone solvent after pretreatment, stir, seal and age, and check to obtain polyvinylidene fluoride glue;

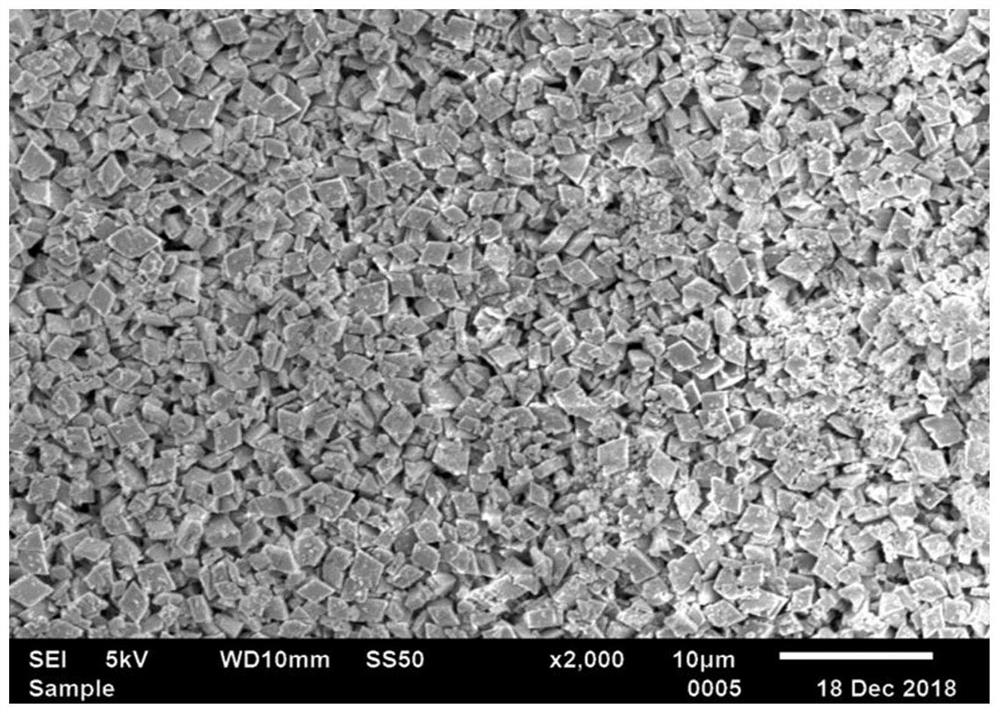

[0046] (2) Dissolving the boehmite powder in N-methylpyrrolidone solvent after pretreatment, stirring and checking to form a boehmite solution;

[0047] (3) Stir and mix the polyvinylidene fluoride glue and the boehmite solution to obtain a boehmite slurry after inspection.

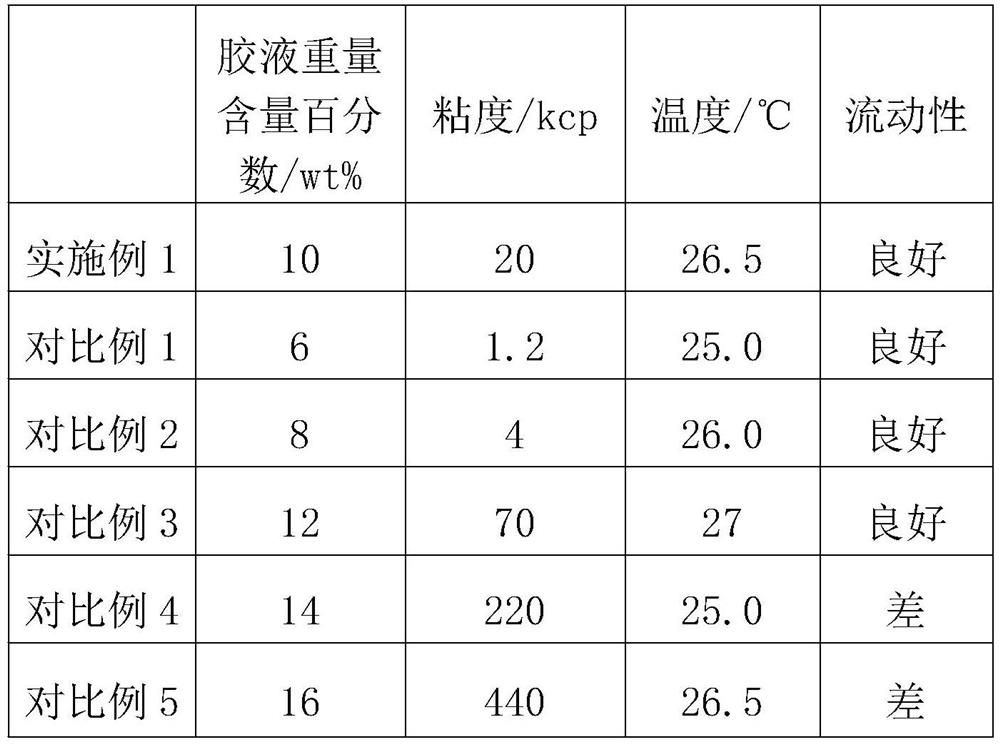

[0048] The weight percentage of the polyvinylidene fluoride glue solution obtained in the step (1) is 10wt%.

[0049] The linear velocity of stirring in the step (1) is 4m / s, and the linear velocity of stirring in the step (2) is 17m / s.

[0050] Stir in the step (1) until no obvious polyvinylidene fluoride micelles are visible in the solution and stop stirring.

[0051] In the step (1), the aging temperature is 50° C., and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com