Mo-containing high-chromium wearproof alloy material and preparation method thereof

A wear-resistant alloy and high-chromium technology, which is applied in the field of Mo-containing high-chromium wear-resistant alloy materials and their preparation, can solve problems such as affecting wear resistance, and achieve the effects of increasing service life, increasing hardness and improving wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

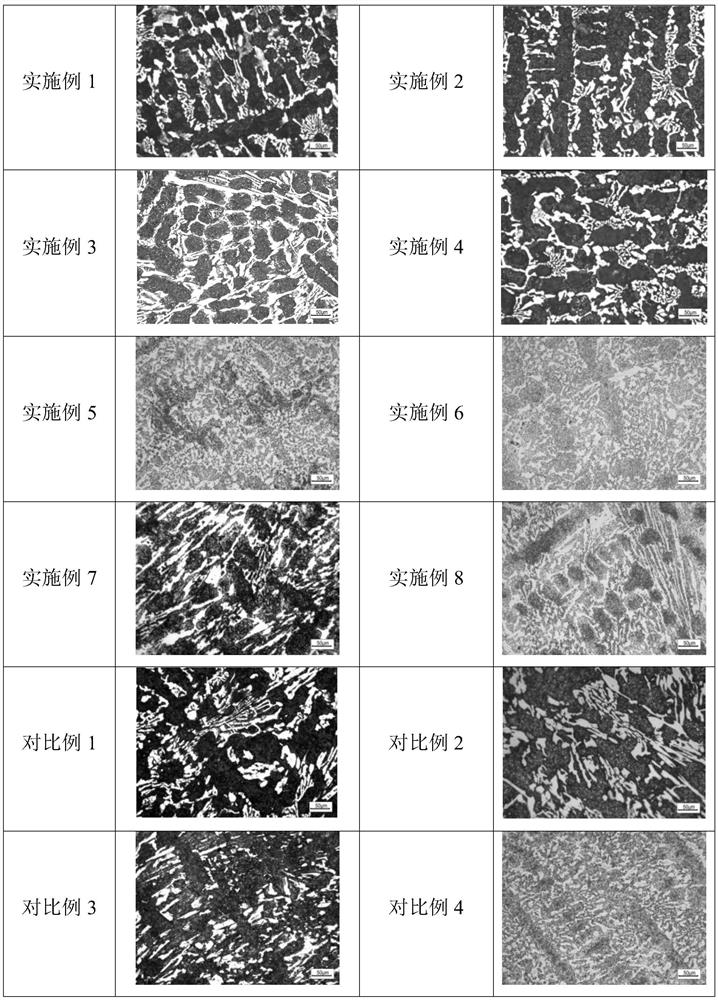

Image

Examples

Embodiment 1

[0029] A high-chromium wear-resistant alloy material containing Mo, including the following components in weight percentage: molybdenum Mo: 1%, chromium Cr: 17%, carbon C: 3%, silicon Si: 0.5%, manganese Mn: 0.55%, phosphorus P: 0.55%, sulfur S: 0.55%, and the rest is Fe.

[0030] The preparation method of the Mo-containing high-chromium wear-resistant alloy material includes the following steps.

[0031] S1: According to the component content and the raw materials used are high-carbon ferrochrome, low-carbon ferrochrome, ferromolybdenum, ferrosilicon, scrap steel, etc., the raw materials used are determined to be high-carbon ferrochrome, low-carbon ferrochrome, ferromolybdenum, Ratio of ferrosilicon, scrap steel, etc., and preparation of charge;

[0032] S2: The raw materials used are high-carbon ferrochrome, low-carbon ferrochrome, ferromolybdenum, ferrosilicon, scrap steel, etc., which are put into an intermediate frequency induction furnace for smelting, and the temperatu...

Embodiment 2

[0036] A high-chromium wear-resistant alloy material containing Mo, including the following components in weight percentage: molybdenum Mo: 1%, chromium Cr: 17%, carbon C: 3%, silicon Si: 0.5%, manganese Mn: 0.55%, phosphorus P: 0.55%, sulfur S: 0.55%, and the rest is Fe.

[0037] The preparation method of the Mo-containing high-chromium wear-resistant alloy material refers to Example 1, the difference is that the tempering treatment in S4 is to raise the temperature from room temperature to 450°C at a certain speed, then keep it warm for 1.5h, take out the casting blank, and air cool to room temperature.

Embodiment 3

[0039] A high-chromium wear-resistant alloy material containing Mo, including the following components in weight percentage: molybdenum Mo: 3%, chromium Cr: 17%, carbon C: 3%, silicon Si: 0.5%, manganese Mn: 0.55%, phosphorus P: 0.55%, sulfur S: 0.55%, and the rest is Fe.

[0040] The preparation method of the Mo-containing high-chromium wear-resistant alloy material is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com