Coating structure and preparation method thereof

A solution and silver layer technology, applied in the field of coating structure and its preparation, can solve the problems of high-frequency and high-speed transmission of signals, loss and other problems, and achieve the effects of cost reduction, low operating temperature, corrosion resistance and friction resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

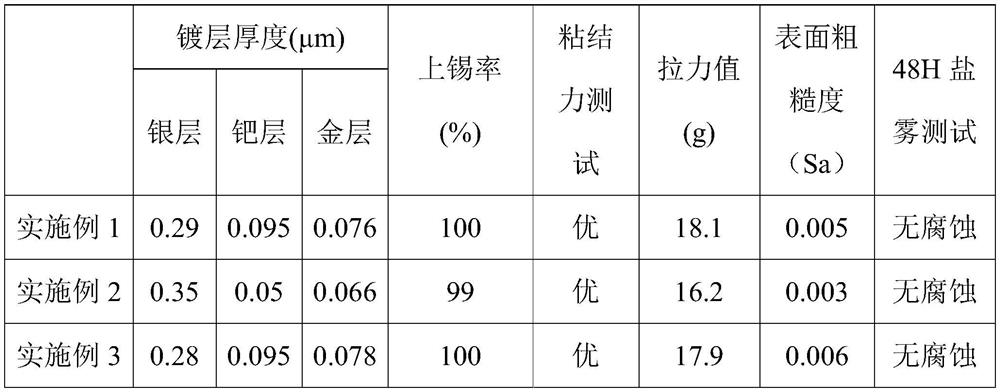

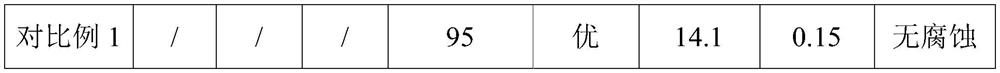

Embodiment 1

[0078] The experimental substrate in this embodiment adopts copper-clad laminate, and the test samples are prepared according to the technological process in Table 1:

[0079] Table 1

[0080] serial number Process name temperature / ℃ time / min 1 degreasing 40 4 2 pure water wash room temperature 0.5 3 microetch 25 2 4 pure water wash room temperature 0.5 5 Prepreg 40 1 6 Preparation of silver layer 50 3 7 pure water wash room temperature 0.5 8 Preparation of palladium layer 52 10 9 pure water wash room temperature 0.5 10 Preparation of gold layer 80 8 11 pure water wash room temperature 0.5

[0081] The process of preparing the silver layer in process flow 6 of Table 1 is as follows: the copper-clad laminate obtained in process flow 5 is placed in a chemical silver solution to obtain a silver layer, the pH of the chemical silver solution is 8.5, and silver ammonia comp...

Embodiment 2

[0085] The experimental base material in this embodiment adopts copper-clad laminate, and the test sample is prepared according to the technological process in Table 2:

[0086] Table 2

[0087] serial number Process name temperature / ℃ time / min 1 degreasing 35 5 2 pure water wash room temperature 0.5 3 microetch 23 2 4 pure water wash room temperature 0.5 5 Prepreg 35 1 6 Preparation of silver layer 40 4 7 pure water wash room temperature 0.5 8 Preparation of palladium layer 40 15 9 pure water wash room temperature 0.5 10 Preparation of gold layer 70 8 11 pure water wash room temperature 0.5

[0088] Table 2 Process flow 6 The process of preparing the silver layer is as follows: the copper clad laminate obtained in process flow 5 is placed in the chemical silver solution to obtain the silver layer, the pH of the chemical silver solution is 9, and the silver sulfite in...

Embodiment 3

[0092] The experimental substrate in this embodiment adopts copper-clad laminate, and the test samples are prepared according to the process flow in Table 3:

[0093] table 3

[0094] serial number Process name temperature / ℃ time / min 1 degreasing 45 3 2 pure water wash room temperature 0.5 3 microetch 27 1 4 pure water wash room temperature 0.5 5 Prepreg 45 1 6 Preparation of silver layer 70 2 7 pure water wash room temperature 0.5 8 Preparation of palladium layer 70 4 9 pure water wash room temperature 0.5 10 Preparation of gold layer 80 20 11 pure water wash room temperature 0.5

[0095] Table 3 Process 6 The process of preparing the silver layer is as follows: the copper clad laminate obtained in process 5 is placed in the chemical silver solution to obtain the silver layer, the pH of the chemical silver solution is 8, and the silver sulfite in the chemical silver ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com