The preparation method of ito thin film and ito transparent conductive glass

A technology of transparent conductive glass and thin film, which is applied in the direction of equipment for manufacturing conductive/semiconductive layers, conductive layers on insulating carriers, vacuum evaporation plating, etc. Affects the electron mobility and optical properties of the film, and the difficulty of controlling the thickness of the nano-scale film, etc., to achieve the effect of excellent transparent conductivity, easy large-scale production, and uniform components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention proposes a kind of preparation method of ITO film, and it comprises the steps:

[0039] S1: substrate cleaning;

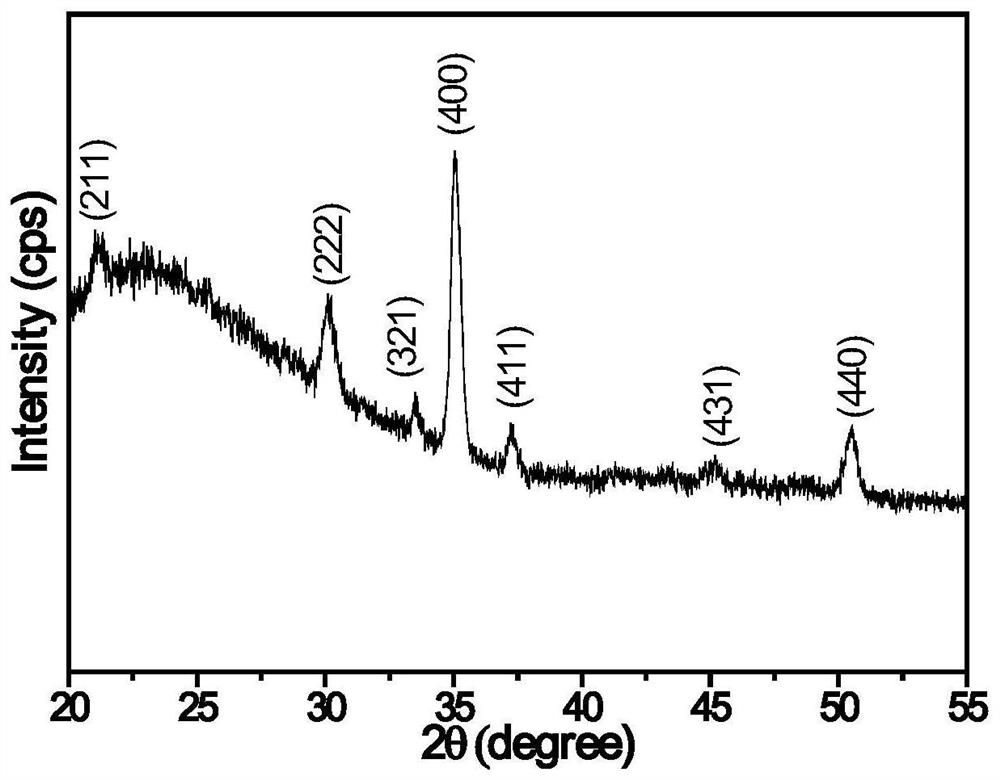

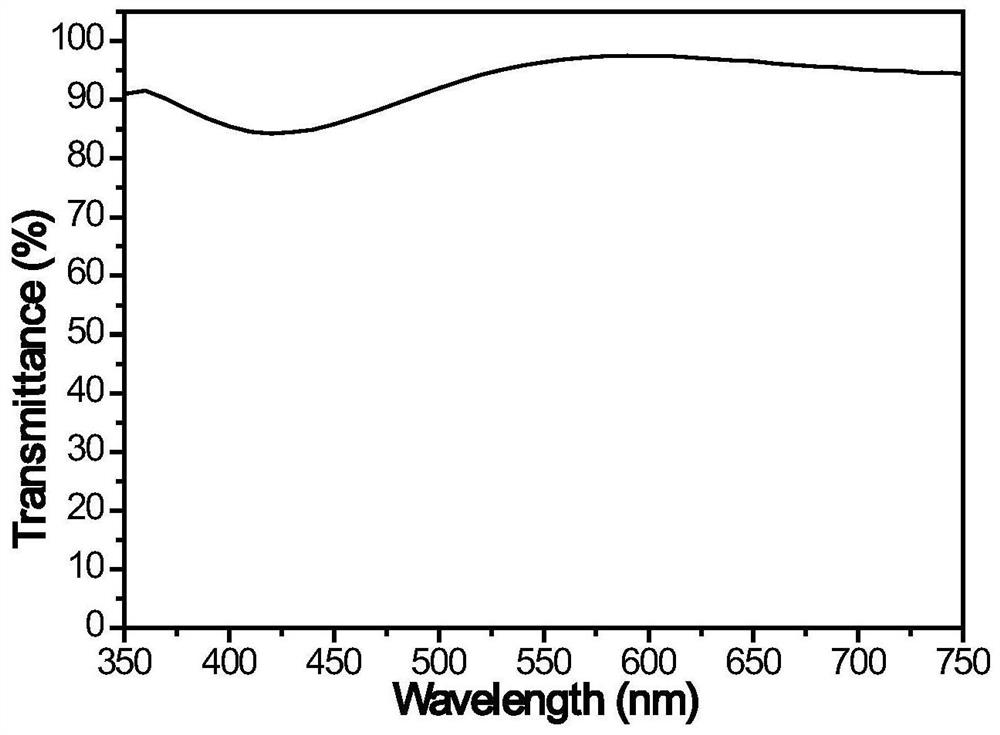

[0040] S2: growing a variable temperature buffer layer on the substrate by magnetron sputtering;

[0041] S3: using magnetron sputtering to grow an oriented growth layer on the temperature-variable buffer layer;

[0042] S4: After the oriented growth layer reaches the set thickness, the growth is stopped; the temperature-variable growth layer and the oriented growth layer together form an ITO thin film.

[0043] In some embodiments of the present invention, in S2, the growth process of the temperature-variable buffer layer is as follows: the initial temperature of the substrate is controlled to 80-120° C., and magnetron sputtering is started to grow the buffer layer. When the buffer layer is deposited every 1 nm , increasing the temperature of the substrate by 0.8-1.2° C. until the thickness of the buffer layer reaches a set thickness...

Embodiment 1

[0054] A preparation method of ITO transparent conductive glass, the specific implementation steps are as follows.

[0055] S1: The substrate is made of alkali-free ultra-thin glass, the content of alkali elements in the alkali-free ultra-thin glass is 0.05 wt%, and the thermal expansion coefficient at room temperature is 35.5×10 -7 / K, thickness 0.4 mm, the substrate was ultrasonically cleaned in acetone, absolute ethanol and deionized water for 10 minutes, and then dried with high-purity nitrogen.

[0056] S2: Magnetron sputtering is used to grow the variable temperature buffer layer. When magnetron sputtering, the sputtering power density is 1.6 W / cm 2 , the sputtering pressure is 0.2 Pa, and the oxygen partial pressure is 0.1%. At the beginning of sputtering, the substrate temperature is 100°C. After that, the substrate temperature is increased by 1°C every time the buffer layer is deposited 1 nm, until the buffer layer When the thickness is 50nm, the growth is stopped an...

Embodiment 2

[0061] A preparation method of ITO transparent conductive glass, the specific implementation steps are as follows.

[0062] S1: The substrate is made of alkali-free ultra-thin glass, the alkali element content in the alkali-free ultra-thin glass is 0.04 wt%, and the thermal expansion coefficient at room temperature is 34.4×10 -7 / K, thickness 0.2 mm, the substrate was ultrasonically cleaned in acetone, absolute ethanol and deionized water for 10 minutes, and then dried with high-purity argon.

[0063] S2: Magnetron sputtering is used to grow the variable temperature buffer layer. When magnetron sputtering, the sputtering power density is 2.4W / cm 2 , the sputtering pressure is 1.0 Pa, and the oxygen partial pressure is 0.4%. At the beginning of sputtering, the substrate temperature is 80°C. After that, the substrate temperature is increased by 0.8°C every time the buffer layer is deposited 1 nm, until the buffer layer When the thickness is 20nm, the growth is stopped and a 20n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com