Preparation method of carbon nano-thin film/nano-micron network composite thin film and fiber

A technology of carbon nano-film and network compounding, applied in chemical instruments and methods, nano-carbon, carbon compounds, etc., can solve problems such as incomplete coordination of neighbors, high surface energy, easy self-melting or decomposition, etc., to simplify production steps, The effect of reducing production cost and lowering the preparation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of a kind of carbon nano film / nano-micro network composite film and fiber provided by the present invention, generally, can comprise the following steps:

[0041] (1) preparing a nano-micro network on the first substrate;

[0042] (2) rewinding the first substrate prepared with the nano-micro network into the growth chamber, and raising the temperature of the first substrate prepared with the nano-micro network under the protection of the reducing gas;

[0043] (3) at a predetermined temperature, introducing a carbon source;

[0044] (4) Make the first substrate prepared with the nano-micro network transport roll-to-roll at a predetermined speed, and directly grow the carbon nanofilm / nano-micro network / first substrate;

[0045] (5) Separating the first substrate and carbon nanofilm / nano-micron network to obtain continuous carbon nanofilm / nano-micron network composite film, continuous carbon nanofilm / nano-micron network composite fiber or carbon n...

Embodiment 1

[0112] Step 1: Electrochemically polish the purchased high-purity copper foil, clean the residual electrolyte on the copper foil, and blow dry.

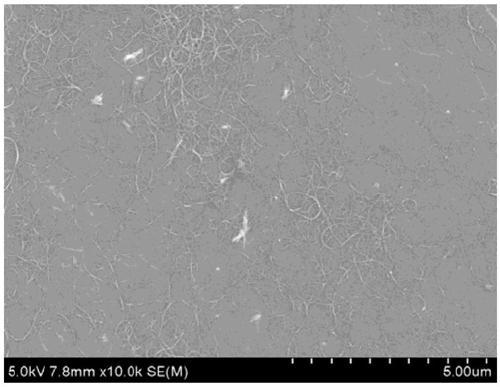

[0113] Step 2: spread the continuously grown carbon nanotube film on the treated copper foil, and wind it on one end of the wheel;

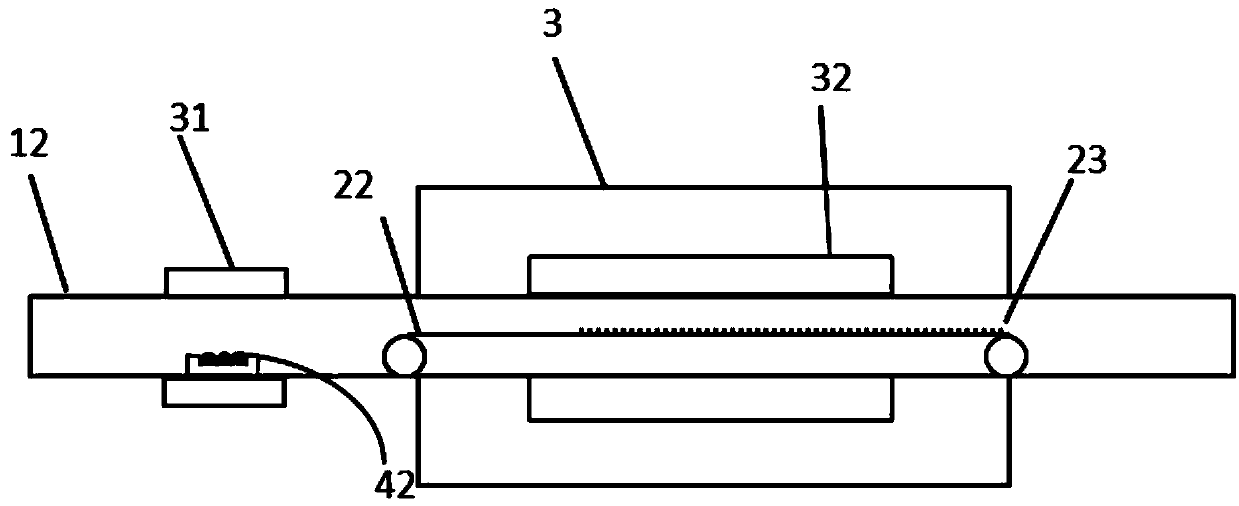

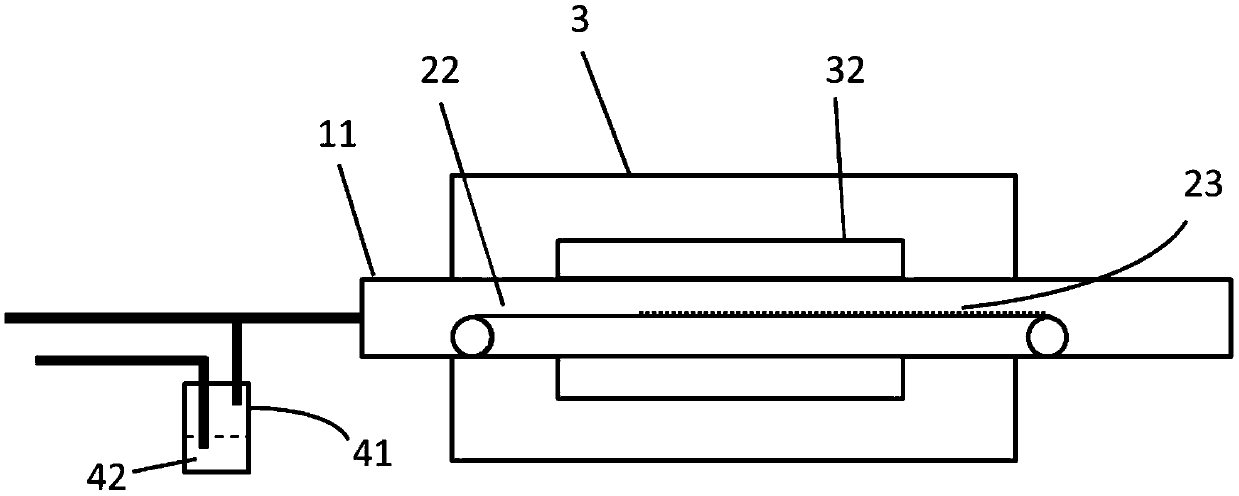

[0114] Step 3: Place the rolled carbon nanotube film / copper foil in the cavity, place the solid naphthalene in a glass bottle and seal it with aluminum foil, drill a small hole on the aluminum foil, and place the glass bottle upstream of the cavity, such as figure 1 shown.

[0115] Step 4: Pass in the cleaning gas to evacuate, and wait until the air is exhausted. In this embodiment, the cleaning gas is high-purity argon with a flow rate of 500 sccm.

[0116] Step 5: Turn off the cleaning gas, and raise the temperature of the cavity 32 to the target temperature T1 under the protection of hydrogen and argon. In this embodiment, the flow rate of hydrogen gas is preferably 30 sccm, the flow rate of argon...

Embodiment 2

[0120] Add melamine powder to the naphthalene powder in Example 1 and mix evenly, wherein the mass ratio of naphthalene powder to melamine powder is between 1:1 and 10:1, and other steps are the same as in Example 1. Finally, a nitrogen-doped graphene / carbon nanotube composite film is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore size | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com