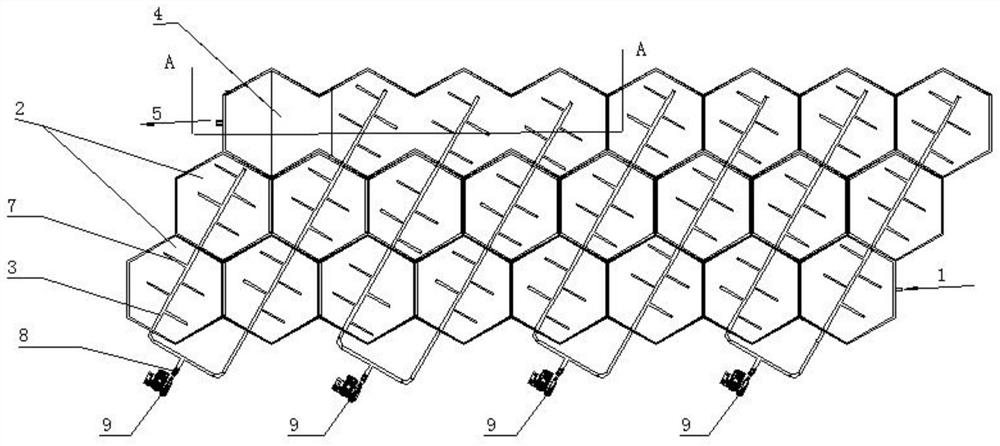

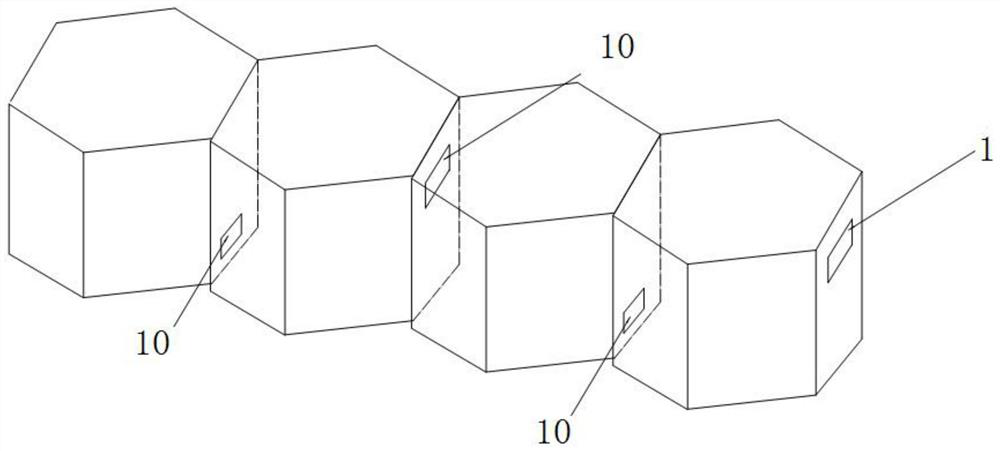

Honeycomb type fermentation digestion device and working method thereof

A working method and honeycomb technology, applied in the field of sewage treatment, livestock and poultry urine, can solve the problems that cannot meet the requirements of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] If the material to be fermented is cow urine, the fermentation process using the honeycomb fermentation and digestion device of the present invention is as follows:

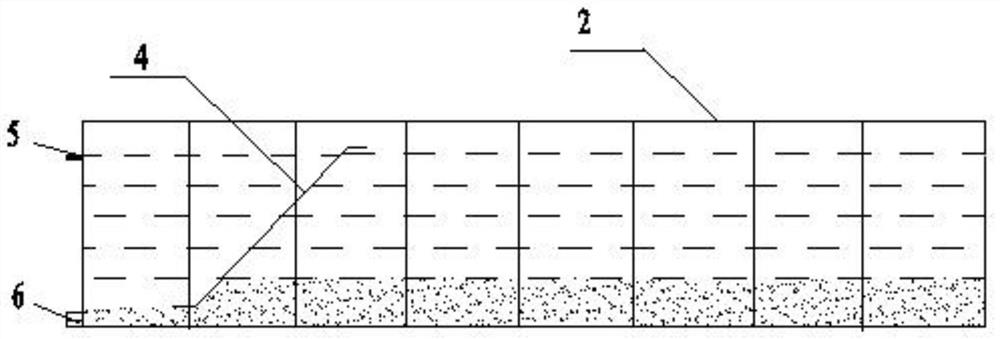

[0035] 1. The feeding port 1 is connected with a metering pump, and the cow urine is added to the first cylinder 2 according to the set amount, so that the daily filling amount can be accurately guaranteed; at the same time, adding biological bacteria to the cow urine can shorten the time of cow urine. Urine fermentation time;

[0036] 2. Driven by the pressure of the metering pump, the cow urine injected in the back will push the cow urine in the front to fill up each cylinder 2 along the Z-shaped route;

[0037] 3. The aeration air compressor 9 injects oxygen into each barrel 2 through the aeration tube to accelerate the propagation of the biological agent, that is, to accelerate the fermentation speed, and at the same time disturb the cow urine through the high-pressure airflow to prevent the residue fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com