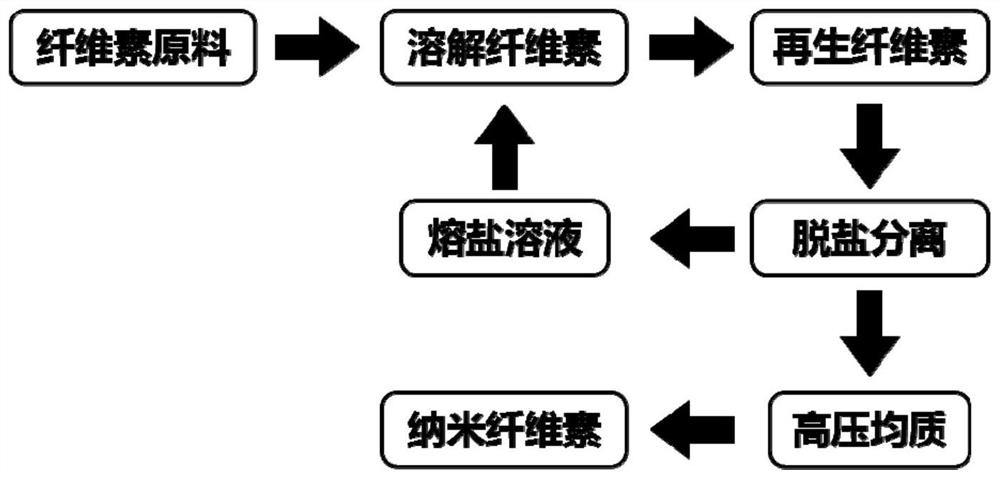

Method for preparing nanoscale regenerated cellulose by adopting molten salt system

A regenerated cellulose, nano-scale technology, applied in the direction of single-component cellulose rayon, fiber chemical characteristics, bulk chemical production, etc., can solve problems such as strict moisture content requirements, restricting industrialization promotion, polluting environmental energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 100 g of molten salt system containing 54% (w / w) LiCl was accurately prepared with pure water. Accurately weigh 1g of microcrystalline cellulose powder, with a solid-to-liquid ratio of 1:100, and add it to the LiCl molten salt system; raise the temperature to 95°C, and continue stirring at 600rpm for 8 hours to completely dissolve the cellulose to obtain a uniform cellulose-molten saline solution. Then the cellulose-molten salt solution was poured into 200 g of water, and filtered to obtain regenerated cellulose. Then redisperse the separated regenerated cellulose in 250g of pure water to form a regenerated cellulose dispersion; homogenize 20 times with a high-pressure homogenizer at 60MPa to obtain a colloidal cellulose nanocrystal dispersion system.

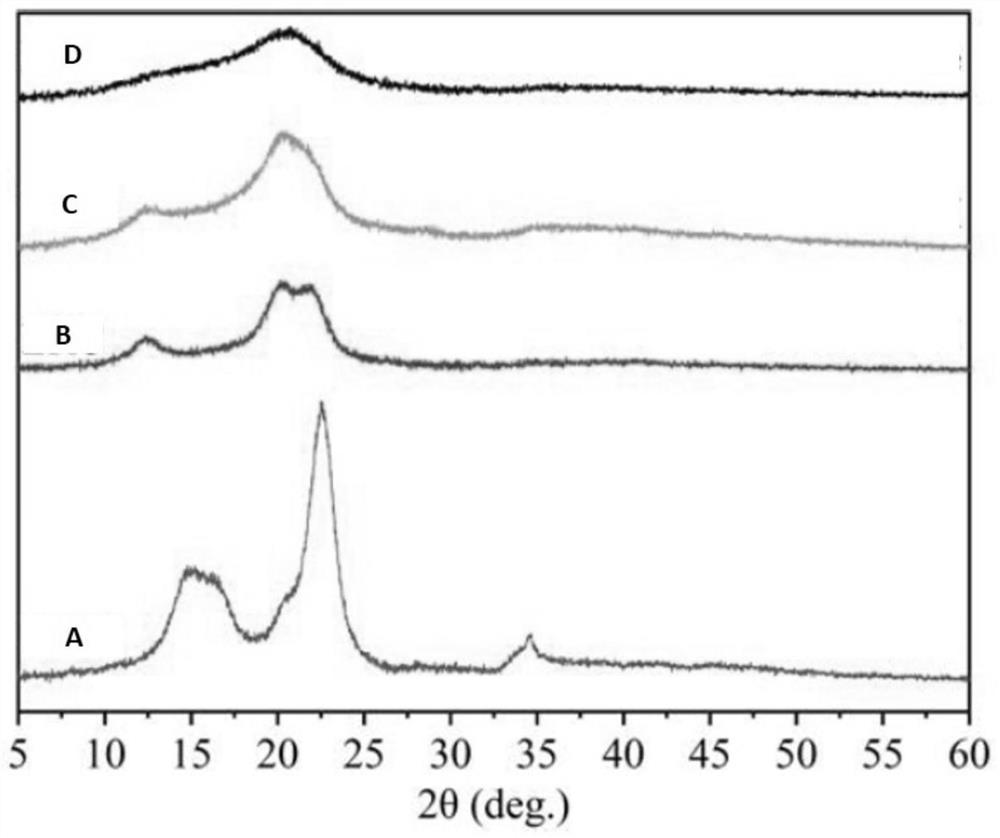

[0037] The yield of cellulose nanocrystals obtained in this embodiment is 98.2% (relative to the original absolute dry microcrystalline cellulose), and the crystal structure of the prepared cellulose nanocrystals is sig...

Embodiment 2

[0039] Accurately prepare 100g of pure water containing 25% (w / w) ZnCl 2 molten salt system. Accurately weigh 2g of dry bleached softwood pulp, with a solid-to-liquid ratio of 1:50, and add it to the ZnCl molten salt system; raise the temperature to 105°C, and continue stirring at 300rpm for 2 hours to completely dissolve the cellulose to obtain a uniform cellulose- molten salt solution. Then pour the cellulose-molten salt solution into 1000 g of pure water, and centrifuge to obtain regenerated cellulose. Then redisperse the separated regenerated cellulose in 300g of pure water to form a regenerated cellulose dispersion; then homogenize for 15 times with a high-pressure homogenizer at 60 MPa to obtain cellulose nanocrystals.

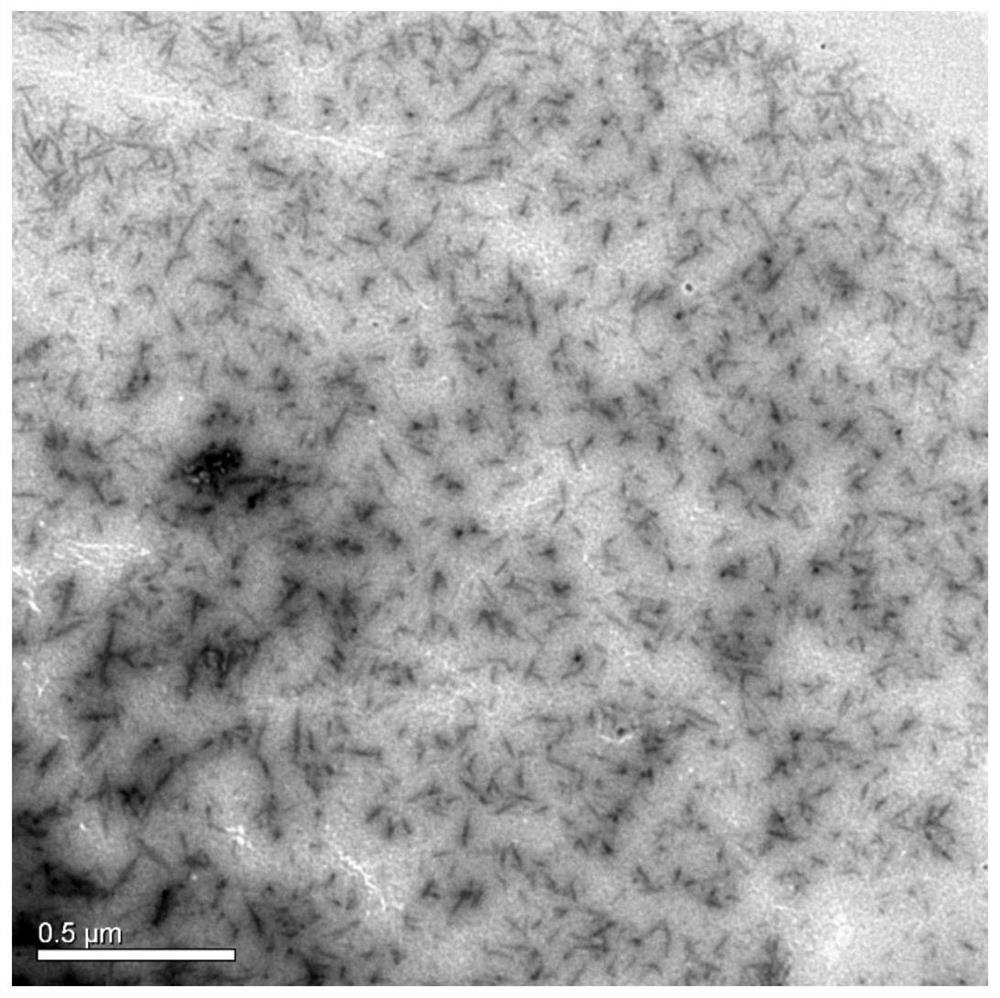

[0040] The yield of the cellulose nanocrystals prepared in this example was 97.4% (relative to the original dry bleached softwood pulp). Cellulose nanocrystals with uniform particle size are prepared. According to the TEM pictures and software statist...

Embodiment 3

[0042] Accurately prepare 100g of 85% (w / w) LiClO with pure water 4 molten salt system. Accurately weigh 12.5g of dry bleached hardwood pulp, and add it to LiClO with a solid-to-liquid ratio of 1:8 4 In the molten salt system, the temperature was raised to 115° C., and the cellulose was completely dissolved after stirring at 400 rpm for 0.5 hour to obtain a uniform cellulose-molten salt solution. Then the cellulose-molten salt solution was poured into 1500g of pure water to obtain flocculent regenerated cellulose immediately. Then filter, and redisperse the separated regenerated cellulose in 400 g of absolute ethanol to form a regenerated cellulose suspension; then homogenize for 15 times with a high-pressure homogenizer at 100 MPa to obtain cellulose nanospheres.

[0043] The yield of the cellulose nanospheres prepared in this example was 99.0% (relative to the original dry bleached hardwood pulp). Cellulose nanospheres with uniform particle size were prepared, and the dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com