Nano seed coating agent and preparation method thereof

A technology of nano-seeds and coating agents, which is applied in the direction of seed coating/seed dressing, coating, etc., and can solve the problem that seed coating agents cannot adapt to various environmental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

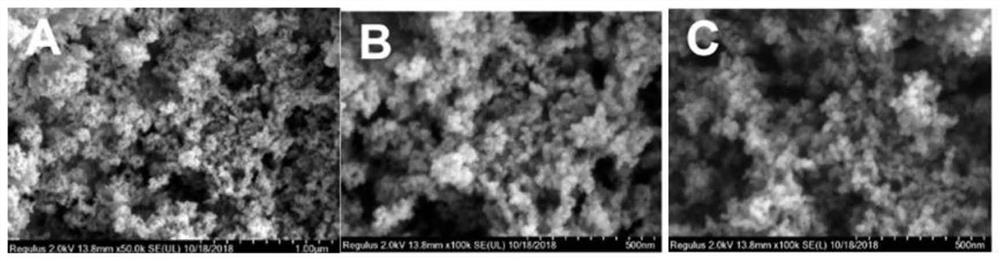

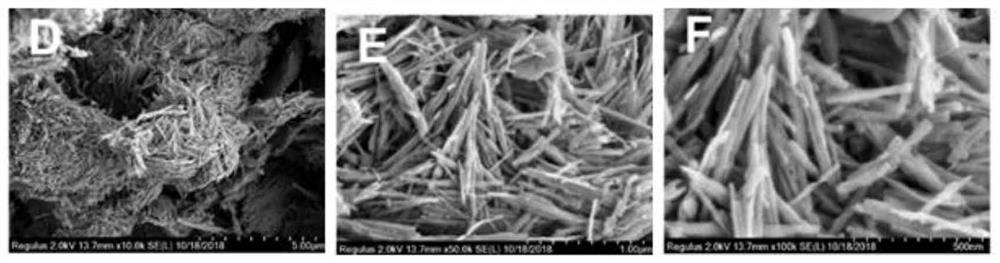

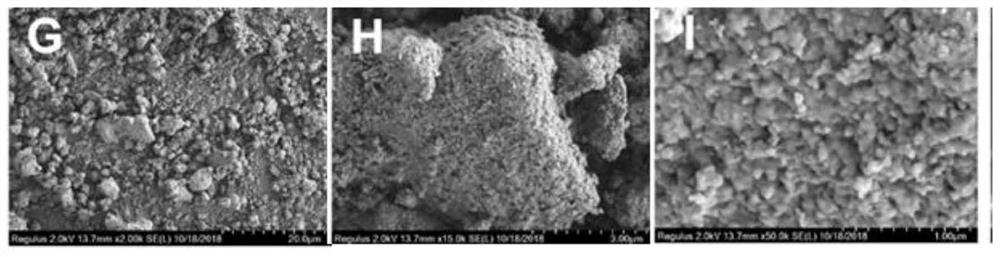

Image

Examples

Embodiment 1

[0047] The nano seed coating agent is mainly made of the following raw materials in parts by weight: 50 parts of modified attapulgite, 20 parts of amino silicone oil, 10 parts of nano-scale silicon dioxide, 50 parts of calcium peroxide, 870 parts of absolute ethanol, modified The mass ratio of attapulgite to calcium peroxide is 1:1.

[0048] The preparation method of nano seed coating agent in the present embodiment comprises the following steps:

[0049] (1) Using oxygen and ammonia as the gas source, the attapulgite powder is intermittently irradiated under vacuum conditions by using a plasma with a temperature of 500 ° C and a power of 1 KW. The irradiation interval is 3 minutes, and kept The effective irradiation time is 30 minutes;

[0050] (2) carry out 200 mesh sieves to the attapulgite obtained in step (1), obtain the modified attapulgite;

[0051] (3) Mix the modified attapulgite with amino silicone oil and silicon dioxide with 870 parts of absolute ethanol, heat an...

Embodiment 2

[0055] The nano seed coating agent is mainly made of the following raw materials in parts by weight: 100 parts of modified attapulgite, 30 parts of amino silicone oil, 20 parts of nanometer silicon dioxide, 100 parts of calcium peroxide, 750 parts of absolute ethanol, modified The mass ratio of attapulgite to calcium peroxide is 1:1.

[0056] The preparation method of nano seed coating agent in the present embodiment comprises the following steps:

[0057] (1) With oxygen and ammonia as the gas source, the attapulgite powder is intermittently irradiated under vacuum conditions by using a plasma with a temperature of 700°C and a power of 1KW. The irradiation interval is 3 minutes, and kept The effective irradiation time is 30 minutes;

[0058] (2) carry out 200 mesh sieves to the attapulgite obtained in step (1), obtain the modified attapulgite;

[0059] (3) Mix the modified attapulgite with amino silicone oil and silicon dioxide with 750 parts of absolute ethanol, heat and s...

Embodiment 3

[0063] The nano seed coating agent is mainly made of the following raw materials in parts by weight: 150 parts of modified attapulgite, 40 parts of amino silicone oil, 30 parts of nano-scale silicon dioxide, 150 parts of calcium peroxide, 630 parts of absolute ethanol, modified The mass ratio of attapulgite to calcium peroxide is 1:1.

[0064] The preparation method of nano seed coating agent in the present embodiment comprises the following steps:

[0065] (1) With oxygen and ammonia as the gas source, the attapulgite powder is intermittently irradiated under vacuum conditions by using a plasma with a temperature of 800°C and a power of 1KW. The irradiation interval is 3 minutes, and kept The effective irradiation time is 30 minutes;

[0066] (2) carry out 200 mesh sieves to the attapulgite obtained in step (1), obtain the modified attapulgite;

[0067] (3) Mix the modified attapulgite with amino silicone oil and silicon dioxide with 630 parts of absolute ethanol, heat and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com