Blast furnace smelting fly ash treatment system and treatment method thereof

A processing system and blast furnace smelting technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problems of not being widely promoted and high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A steel company uses 230m 3 Blast furnace smelting is used for fly ash treatment, and about 60 tons of fly ash need to be processed every day. Build a 60m 3 fly ash storage tank, a 120m 3 The mixed material storage tank and a pre-mixing gyratory equipment, other equipment adopts the original equipment of the factory; the fly ash from the waste incineration power plant is transported to the treatment site by closed tank trucks, and the fly ash is transported to the fly ash storage tank through the airflow.

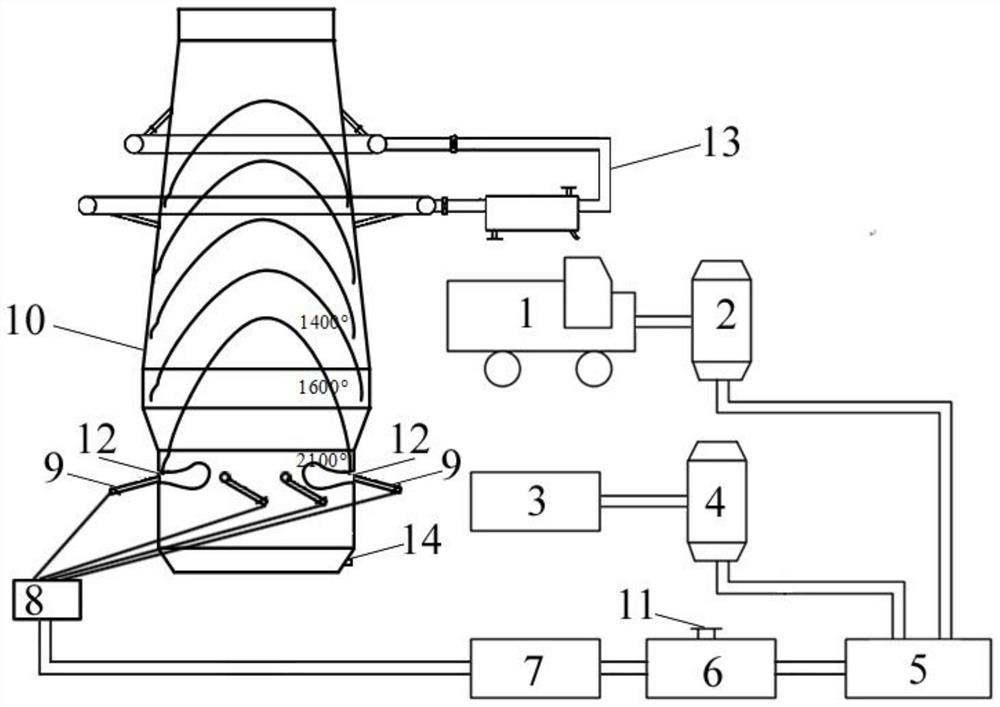

[0028] Such as figure 1 As shown, a blast furnace smelting fly ash treatment system includes a closed tank car 1, a fly ash storage tank 2, a coal grinding device 3, a pulverized coal storage tank 4, a pre-mixing rotary device 5, a mixture storage tank 6, and an injection tank 7 , distributor 8, spray gun 9 and blast furnace 10;

[0029] The top of the mixture storage tank 6 is provided with an explosion-proof hole 11; the furnace hearth of the blast furnace 10 i...

Embodiment 2

[0043] The blast furnace smelting fly ash processing system of Example 1 is used to process about 60 tons of fly ash per day.

[0044] A processing method for a blast furnace smelting fly ash processing system, comprising the following steps:

[0045] Step 1, mix:

[0046] The fly ash in the airtight tank car 1 is transported to the fly ash storage tank 2 by means of air flow transport, and the transport gas is dry air; the anthracite with a calorific value of 25000KJ is ground in the coal grinding device 3 into coal powder with a particle size of <2 mm, and transported to the pulverized coal storage tank 4 through the airflow; then the fly ash and pulverized coal are simultaneously transported to the pre-mixing cyclone device 5 through the pipeline for uniform mixing, and the mixing mass ratio of the fly ash and pulverized coal is 35:65. into mixed powder, and transported to the mixed material storage tank 6 by air flow for storage;

[0047] Step 2, injecting: use air flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com