A processing technology of chrome-zirconium-copper contact wire for high-speed electrified railway

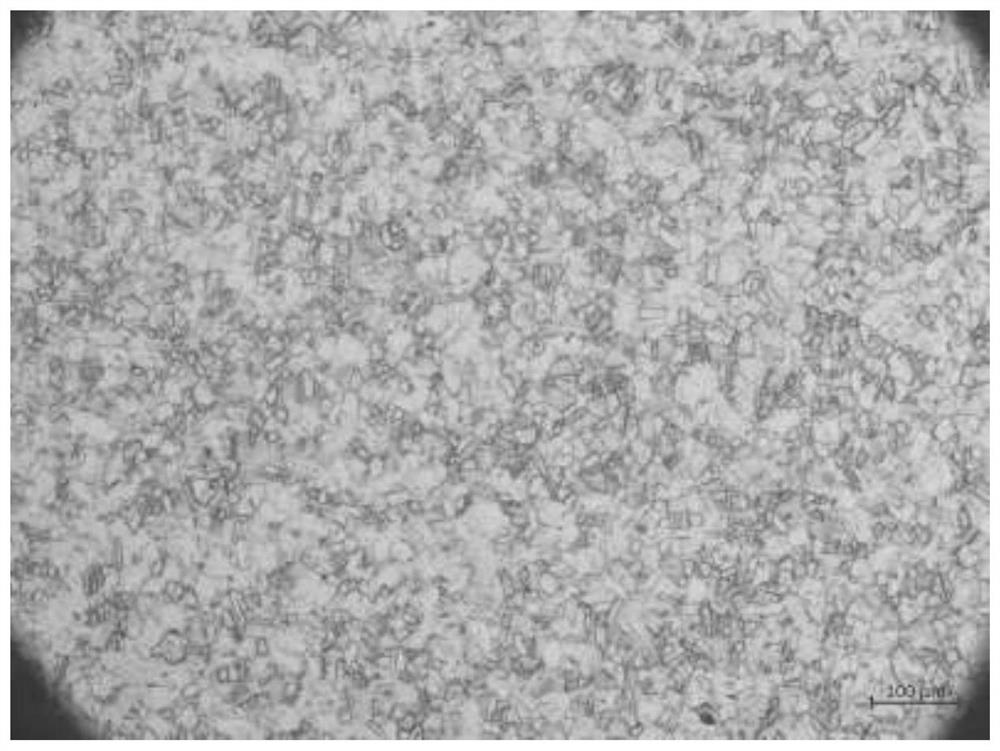

A technology of electrified railway and processing technology, which is applied in the direction of circuits, electrical components, conductive materials, etc., can solve the problems that cannot meet the requirements of electrified railway contact wire products, cannot realize continuous production of large length and large unit weight, and cannot realize industrialized production, etc. , to achieve the effects of fine grain size, consistent performance structure, and improved mechanical properties of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A process for processing chromium-zirconium-copper contact wires for high-speed electrified railways, specifically carried out according to the following steps:

[0026] Step 1: Use upward continuous casting technology to obtain chromium-zirconium copper rods, use upward-oriented oxygen-free copper rods, copper-chrome core-covered wires, and copper-zirconium core-covered wires as raw materials, and cast chromium-zirconium copper rods on the upward vertical continuous casting machine Copper rods are drawn up and continuously cast to obtain upcast chromium-zirconium-copper copper rods whose composition satisfies Cr: 0.6%, Zr: 0.06%, and Cu: the balance, and the copper content of the uplinked oxygen-free copper rods is above 99.97%. , and the oxygen content is lower than 5ppm, and the uplifting speed is controlled to 1200mm / min, and the uplifting cast chromium-zirconium copper copper rod with a copper rod diameter of Φ25mm is selected as the copper rod disc round material; ...

Embodiment 2

[0034] The difference from the first embodiment is that:

[0035]Chromium-zirconium copper rods are obtained by adopting upward continuous casting technology. Using upward-oriented oxygen-free copper rods, copper-chrome core-covered wires, and copper-zirconium core-covered wires as raw materials, the chrome-zirconium copper rods are cast on the vertical continuous casting machine. Leading and continuous casting to obtain an upward casting chromium-zirconium copper copper rod whose composition satisfies Cr: 0.8%, Zr: 0.09%, Cu: the balance, the copper content of the upward leading oxygen-free copper rod is more than 99.97%, and contains The oxygen content is lower than 5ppm, and the uplift speed is controlled at 800mm / min. The uplift casting chromium-zirconium copper copper rod with a copper rod diameter of Φ25mm is selected as the round material for the copper rod.

[0036] Get: the cross-sectional area is 121mm 2 , Tensile strength: 670Mpa, softening rate: 95%, elongation: 6...

Embodiment 3

[0038] The difference from the second embodiment is that:

[0039] Chromium-zirconium copper rods are obtained by adopting upward continuous casting technology. Using upward-oriented oxygen-free copper rods, copper-chrome core-covered wires, and copper-zirconium core-covered wires as raw materials, the chrome-zirconium copper rods are cast on the vertical continuous casting machine. Leading and continuous casting to obtain an upward casting chromium-zirconium-copper copper rod whose composition satisfies Cr: 1.0%, Zr: 0.2%, and Cu: the balance. The copper content of the upward-leading oxygen-free copper rod is above 99.97%, and contains The oxygen content is lower than 5ppm, and the uplift speed is controlled at 800mm / min. The uplift casting chromium-zirconium copper copper rod with a copper rod diameter of Φ30mm is selected as the round material for the copper rod.

[0040] Step 4: rolling the round rod material obtained from step 3 after solution heat treatment, and rolling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com