Hollow MXenes-based metal oxide composite material and preparation method and application thereof

A technology of composite materials and oxides, which is applied in the field of hollow MXenes-based metal oxide composite materials and its preparation, can solve the problems of material loss, insignificant effect of microscopic layering, and inability to greatly improve the performance of supercapacitors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] A preparation method of a hollow MXenes-based metal oxide composite material, comprising the following steps:

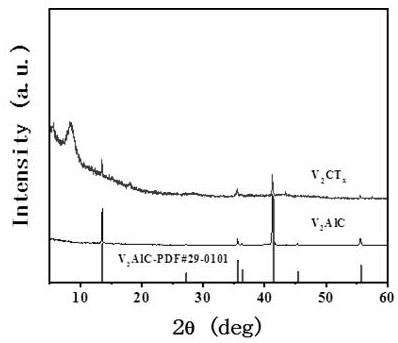

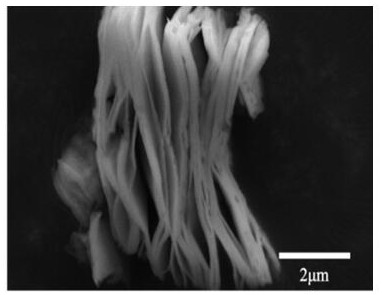

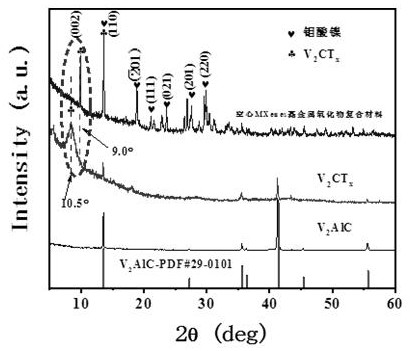

[0088] Step 1) Preparation of multilayer MXenes powder, weigh 1 g V 2 The AlC MAX powder material was placed in 50 mL of 40% HF aqueous solution and stirred for 95 h at room temperature, and then centrifuged for the first time at a high speed of 5000 rpm and a centrifugation time of 10 min. In order to protect the microscopic morphology of the material and reduce the material loss, after the upper waste liquid was poured out, in order to reduce the material loss and protect the microscopic appearance of the material, the centrifugation time was 5 min at a low speed of 3500 rpm. Carry out the second centrifugation under the conditions to make the material fluffy to further deepen the layering effect and remove the impurities remaining in the material, repeat the second centrifugation operation 10 times, at the same time, make the pH value of the solution betwee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com