Method for debitterizing walnut peptide by utilizing sugar alcohol liposome precursor

A liposome precursor and walnut peptide technology, which is applied in plant protein processing, food science, etc., can solve the problems of affecting product taste and reducing the nutritional value of walnut hydrolyzate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

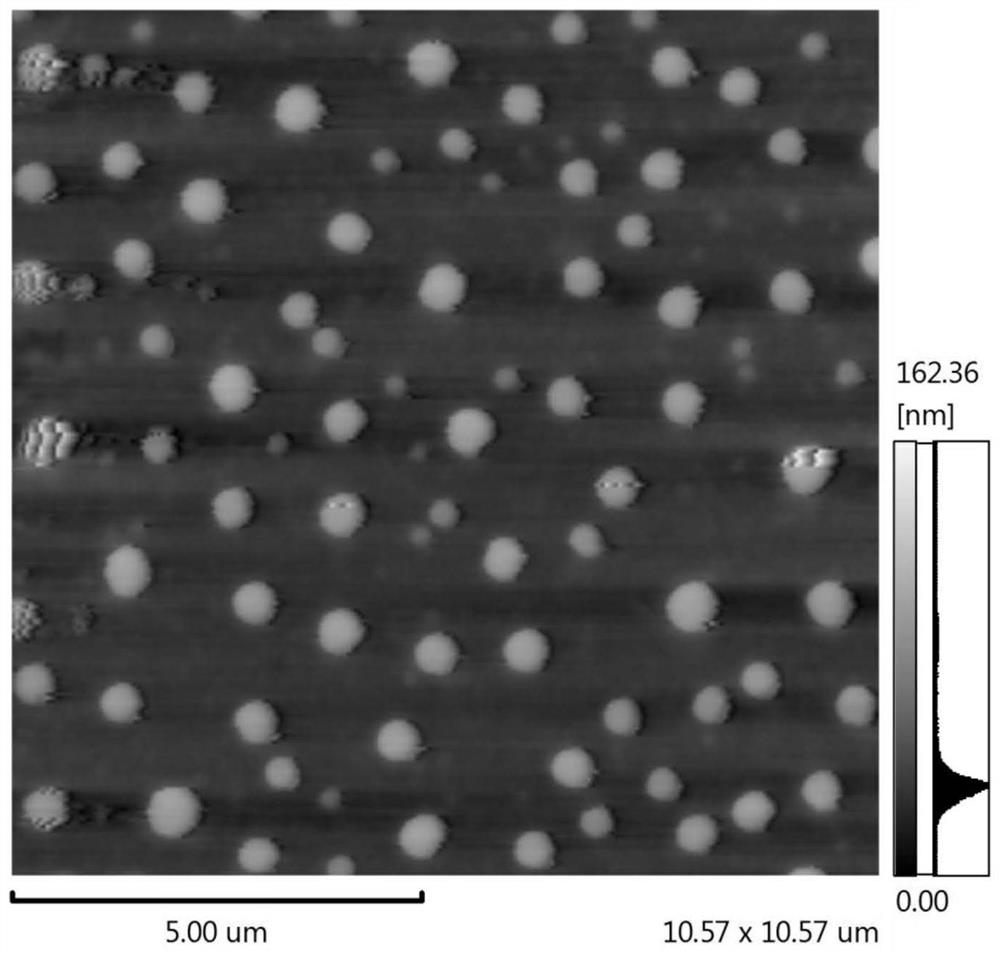

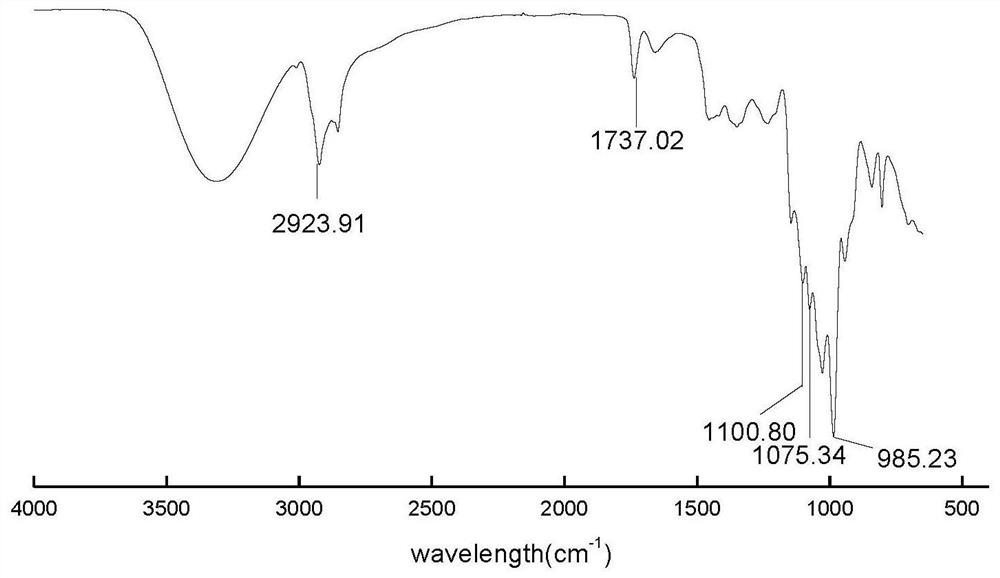

Image

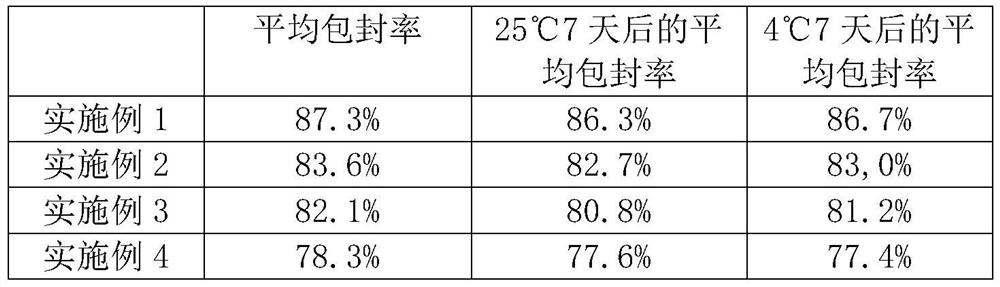

Examples

Embodiment 1

[0036] A method utilizing sugar alcohol liposome precursor debittering walnut peptide, comprising the following steps:

[0037] (1) Accurately weigh 400 mg of soybean lecithin, 80 mg of cholesterol and 320 mg of Tween into a 100 mL beaker, pour 30 mL of absolute ethanol solution into it, and put it into an ultrasonic cleaner for 10 minutes to disperse it evenly to obtain a mixed solution;

[0038] (2) Pour the mixed solution in step (1) into a rotary evaporator until a transparent lipid film is formed;

[0039] (3) Weigh 40 mg of walnut peptide and 1600 mg of sucrose as a lyoprotectant and add them to phosphate buffered saline (PBS), pH=7.4;

[0040] (4) Pour the phosphate buffered saline (PBS) in the step (3) into the rotary flask of the step (2), and hydrate the lipid film;

[0041] (5) Ultrasonicate the hydrated lipid film in step (4), ultrasonicate for 1s, stop for 1s, and circulate for 15min to obtain liposome precursor suspension;

[0042] (6) Pre-freeze the liposome s...

Embodiment 2

[0044] (1) Accurately weigh 480 mg of soybean lecithin, 80 mg of cholesterol and 240 mg of Tween into a 100 mL beaker, pour 30 mL of absolute ethanol solution, and put it into an ultrasonic cleaner for 10 minutes to disperse it evenly to obtain a mixed solution;

[0045] (2) Pour the mixed solution in step (1) into a rotary evaporator until a transparent lipid film is formed;

[0046] (3) Weigh 48 mg of walnut peptide and 1600 mg of trehalose, a lyoprotectant, and add them to phosphate buffered saline (PBS), pH=7.4;

[0047] (4) Pour the phosphate buffered saline (PBS) in the step (3) into the rotary flask of the step (2), and hydrate the lipid film;

[0048] (5) Ultrasonicate the hydrated lipid film in step (4), ultrasonicate for 1s, stop for 1s, and circulate for 15min to obtain liposome precursor suspension;

[0049] (6) Pre-freeze the liposome suspension in step (5) at -80°C for 12 hours, and then freeze it in a freeze dryer for 48 hours to obtain the sugar alcohol liposo...

Embodiment 3

[0051] (1) Accurately weigh 320 mg of soybean lecithin, 80 mg of cholesterol and 400 mg of Tween into a 100 mL beaker, pour 30 mL of absolute ethanol solution into it, and put it into an ultrasonic cleaner for 10 minutes to disperse it evenly to obtain a mixed solution;

[0052] (2) Pour the mixed solution in step (1) into a rotary evaporator until a transparent lipid film is formed;

[0053] (3) Weigh 32 mg of walnut peptide and 800 mg of mannitol, a lyoprotectant, and add them to phosphate buffered saline (PBS), pH=7.4;

[0054](4) Pour the phosphate buffered saline (PBS) in the step (3) into the rotary flask of the step (2), and hydrate the lipid film;

[0055] (5) Ultrasonicate the hydrated lipid film in step (4), ultrasonicate for 1s, stop for 1s, and circulate for 15min to obtain liposome precursor suspension;

[0056] (6) Pre-freeze the liposome suspension in step (5) at -80°C for 12 hours, and then freeze it in a freeze dryer for 48 hours to obtain the sugar alcohol l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com