Method for preparing Pt-Cu nano sheet-like alloy from aqueous phase

A kind of nano-sheet, water-phase preparation technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: Preparation 1 of Pt-Cu nano flake alloy

[0025] With copper chloride as solute and deionized water as solvent, configure 30 milliliters of copper chloride solution with a concentration of 45 mmol / L; add 1.0 g of cetyltrimethylammonium chloride and stir for 20 minutes; add 4 Milliliters, the concentration is 1.0 mol / liter ascorbic acid, stirs 5 minutes; Add 4 milliliters, the concentration is the chloroplatinic acid of 10 mmoles / liters in the mixed solution, put into reaction kettle after stirring for 1 minute, at 120 degrees centigrade The reaction time is 1 hour; the obtained product is separated by a centrifuge, firstly dispersed in deionized water and then ultrasonically centrifuged for the second time, dispersed in ethanol for ultrasonically, centrifuged again, repeated twice, and then dried in a blast drying oven , the drying temperature is preferably 40-50 degrees Celsius, and finally a Pt-Cu nano-sheet alloy is obtained.

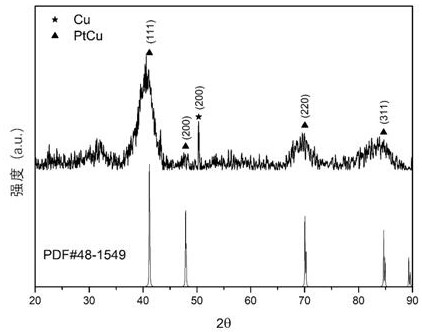

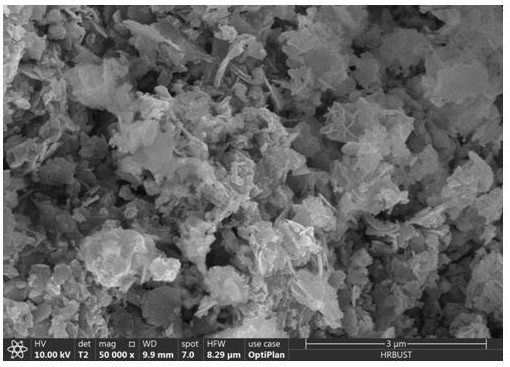

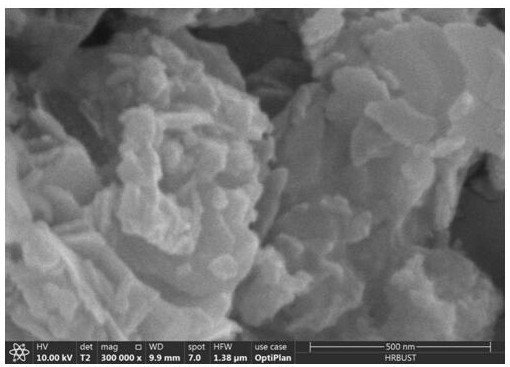

[0026] We perform X-ray ...

Embodiment 2

[0029] Embodiment 2: Exploration about the formation mechanism of nanosheet structure

[0030] In order to explore the reason of Pt-Cu nano flake alloy, we change "concentration is the cupric chloride solution of 15 mmol / liter" to "concentration is the copper chloride solution of 15 mmol / liter" in embodiment 1, Change "4 milliliters, concentration is the chloroplatinic acid of 10 mmol / liter" to "12 milliliters, concentration is the chloroplatinic acid of 10 mmol / liter ", other conditions are constant, its product X-ray diffraction image is as Figure 5 .

[0031] Figure 5 It can be seen that the product obtained in Example 2 is still a Pt-Cu alloy, and does not contain Cu simple substance. but from Figure 6 From the scanning electron microscope image, we can know that the Pt-Cu nano-alloy structure is a nanosphere with a particle size of about 50nm. From this, we can conclude that when the concentration of copper source increases, the reduction reaction process slows dow...

Embodiment 3

[0032] Embodiment 3: Preparation 2 of Pt-Cu nano flake alloy

[0033] In order to explore the influence of the heating rate on the structure of the product, we changed the "reaction at 120 degrees Celsius, the reaction time is 1 hour" in Example 1 to "react at 80 degrees Celsius, the reaction time is 1 hour, and then react at 120 degrees Celsius. Reaction, the reaction time is 1 hour" other experimental conditions remain unchanged. The scanning electron microscope image is Figure 7 .

[0034] From Figure 7 It can be seen that the obtained product is still a sheet structure, which shows that the method can form alloy nanosheets under the experimental environment of 120 degrees Celsius, and the structure of the obtained product is not affected by the heating rate, and the repeatability is high.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com