Continuous production process of p-nitrophenol

A production process, p-nitrophenol technology, applied in the field of waste sulfuric acid concentration, can solve the problems of cooling crystallization process error, low automation level, low yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

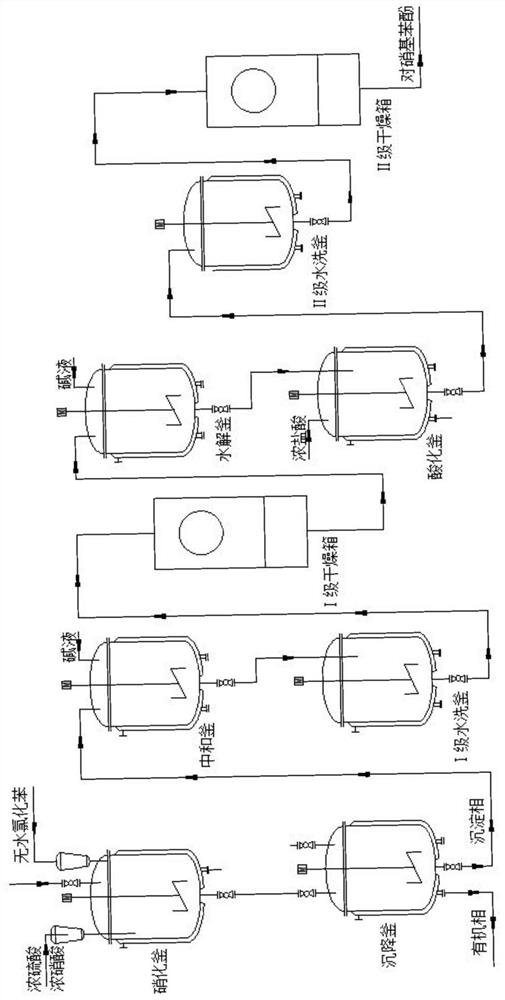

[0030] Such as figure 1 As shown, a continuous production process of p-nitrophenol, the continuous production process is based on a set of continuous production system, the front end of the continuous production system is set as a nitration tank, and the two ends of the nitro tank are respectively equipped with chlorobenzene spray tanks and acid spray tanks , the downstream of the nitration tank is provided with a settling tank, the downstream of the settling tank is equipped with a neutralization tank, the downstream of the neutralization tank is equipped with a first-level washing tank, the downstream of the water-washing tank is equipped with a first-level drying oven, and the downstream of the first-level drying oven is set There is a hydrolysis kettle, and the downstream of the hydrolysis kettle is equipped with a pickling kettle, the downstream of the pickling kettle is equipped with a second-level washing kettle, and the downstream of the second-level washing kettle is e...

Embodiment 2

[0046] The difference between this embodiment and embodiment 1 is:

[0047] A continuous production process of p-nitrophenol, the continuous production process comprises the following steps:

[0048] 1). Nitrification: transfer anhydrous chlorobenzene to the chlorobenzene spray tank, mix the concentrated sulfuric acid and concentrated nitric acid and transfer to the acid spray tank, and add nitrite as the nitration positioning agent, and spray the spray tank into the nitration tank at the same time Inside, control the reaction temperature inside the nitration tank to be 40°C, and the reaction pressure to be 0.15Mpa. After the spray is complete, stir at a stirring rate of 500r / min until the amount of each substance does not change;

[0049] The molar ratio of anhydrous chlorinated benzene, sulfuric acid, nitric acid and nitrite is 1:1:3:0.1;

[0050] 2). Settling: transfer the nitrochlorobenzene mixture after the nitration reaction and the waste sulfuric acid produced by nitra...

Embodiment 3

[0062] The difference between this embodiment and embodiment 1, 2 is:

[0063] A continuous production process of p-nitrophenol, the continuous production process comprises the following steps:

[0064] 1). Nitrification: transfer anhydrous chlorobenzene to the chlorobenzene spray tank, mix the concentrated sulfuric acid and concentrated nitric acid and transfer to the acid spray tank, and add nitrite as the nitration positioning agent, and spray the spray tank into the nitration tank at the same time Inside, control the reaction temperature inside the nitration tank to be 60°C, and the reaction pressure to be 0.3Mpa. After the spray is complete, stir at a stirring rate of 800r / min until the amount of each substance does not change;

[0065] The molar ratio of anhydrous chlorinated benzene, sulfuric acid, nitric acid and nitrite is 5:10:20:1;

[0066] 2). Settling: transfer the nitrochlorobenzene mixture after the nitration reaction and the waste sulfuric acid produced by nit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com