Permeation cementation type polyurethane grouting material for soil body seepage prevention and reinforcement

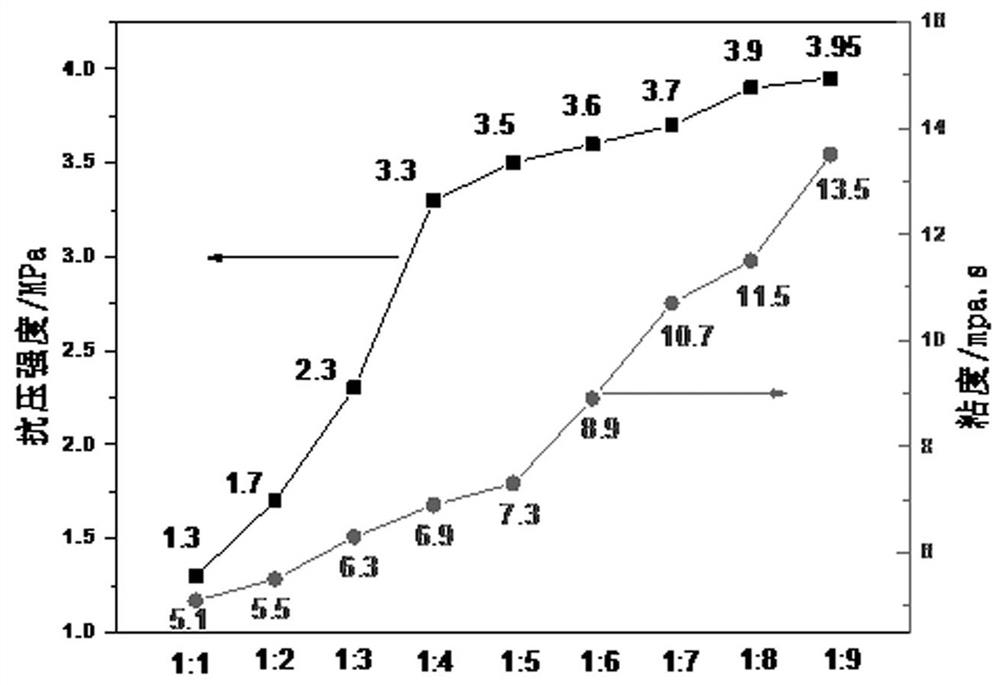

A grouting material, polyurethane technology, applied in soil protection, infrastructure engineering, construction, etc., can solve problems such as poor permeability, high viscosity of infiltrating material, and poor soil consolidation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The invention discloses a permeable cementing type polyurethane grouting material used for anti-seepage and reinforcement of soil, which consists of component A and component B. Component A, in parts by weight, includes:

[0030] Hydrophilic low viscosity polyether polyol: 45 parts;

[0031] Osmotic diluent (dichloromethane and dimethyl carbonate mass ratio is 1:4): 53 parts

[0032] Surfactant (polyol type nonionic surfactant, Aladdin's reagent): 1 part;

[0033] Catalyst (dimethyl benzyl amine, Sinopharm reagent): 0.4 parts;

[0034] Catalyst (diethylenetriamine, Sinopharm Reagent): 0.6 parts;

[0035] Component B: in parts by weight, comprising: PB-1080 (Wanhua Chemical Group Co., Ltd.): 60 copies;

[0036] Osmotic diluent (dichloromethane and dimethyl carbonate mass ratio is 1:4): 20 parts

[0037] Flame retardant (tris(1-chloro-2-propyl) phosphate): 20 parts.

[0038] Preparation process: at room temperature (25°C), weigh each raw material in component A and ...

Embodiment 2

[0040] The invention discloses a permeable cementing type polyurethane grouting material used for anti-seepage and reinforcement of soil, which consists of component A and component B. Component A, in parts by weight, includes:

[0041] Hydrophilic low viscosity polyether polyol: 60 parts;

[0042] Osmotic diluent (dichloromethane and dimethyl carbonate mass ratio is 1:5): 36 parts

[0043] Surfactant (polyoxyethylene type nonionic surfactant, Aladdin's reagent): 2 parts;

[0044] Catalyst (triethylamine, Sinopharm reagent): 1 part;

[0045] Catalyst (diethylenetriamine, Sinopharm reagent): 1 part;

[0046] Component B: in parts by weight, including PB-1080 (Wanhua Chemical Group Co., Ltd.): 70 copies;

[0047] Osmotic diluent (dichloromethane and dimethyl carbonate mass ratio is 1:5): 15 parts

[0048] Flame retardant (tris(1-chloro-2-propyl) phosphate): 15 parts.

[0049] The preparation method is the same as in Example 1.

Embodiment 3

[0051] The invention discloses a permeable cementing type polyurethane grouting material used for anti-seepage and reinforcement of soil, which consists of component A and component B. Component A, in parts by weight, includes:

[0052] Hydrophilic low viscosity polyether polyol: 37 parts;

[0053] Osmotic diluent (dichloromethane and dimethyl carbonate mass ratio is 1:6): 59 parts

[0054] Surfactant (polyoxyethylene type nonionic surfactant, Aladdin's reagent): 2 parts;

[0055] Catalyst (triethylamine, Sinopharm reagent): 0.5 parts;

[0056] Catalyst (diethylenetriamine, Sinopharm reagent): 1.5 parts;

[0057] Component B, in parts by weight, includes: PB-1080 (Wanhua Chemical Group Co., Ltd.): 70 copies;

[0058] Osmotic diluent (dichloromethane and dimethyl carbonate mass ratio is 1:6): 25 parts

[0059] Flame retardant (tris(1-chloro-2-propyl) phosphate): 20 parts.

[0060] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com