Perfluorosulfonic acid ion exchange membrane with high proton conduction and preparation method thereof

A perfluorosulfonic acid ion and perfluorosulfonic acid membrane technology, applied in the field of ion exchange membranes, can solve the problems of ion exchange membrane dimensional stability to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

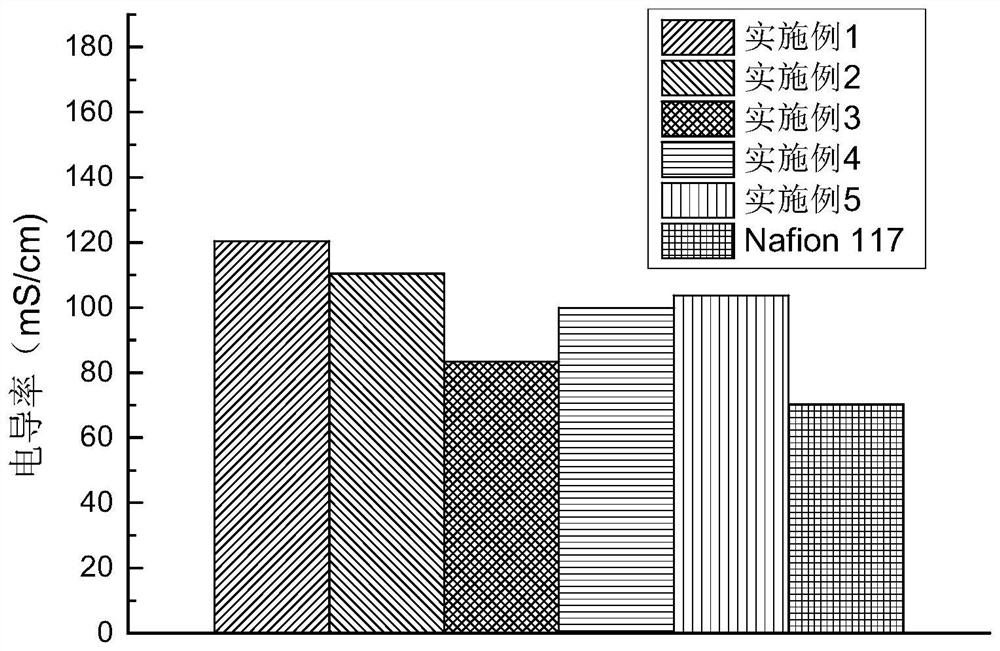

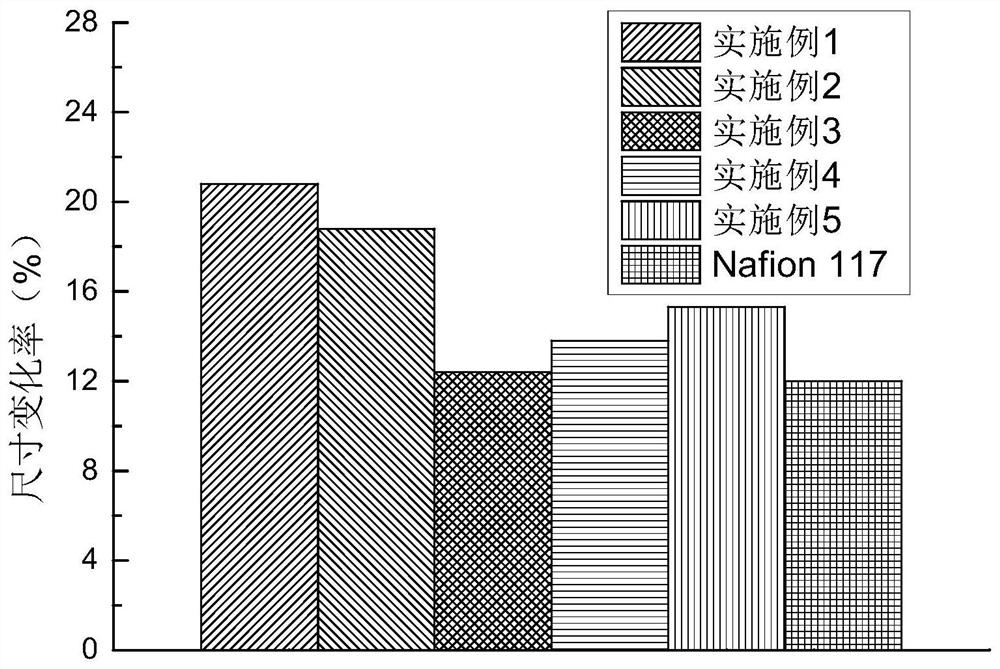

Embodiment 1

[0032] (1) 40wt% sulfonated graphene and 60wt% short-chain branched perfluorosulfonic acid resin are mixed uniformly in proportion, and then melted and extruded by a twin-screw extruder to obtain sulfonated graphene doping after granulation Perfluorosulfonic acid resin masterbatch, melt processing temperature is 200 ℃. The number of layers of the sulfonated graphene is 5 layers, the radial dimension is 500nm, the thickness is 20nm, and the S element content is 6wt%.

[0033] (2) The sulfonated graphene-doped perfluorosulfonic acid resin masterbatch of 50wt% prepared in step (1) is mixed in proportion with the short-chain branched perfluorosulfonic acid resin of 50wt%, and then extruded by twin-screw The machine was melt-extruded to form a film to obtain a perfluorosulfonic acid film doped with sulfonated graphene. The melting processing temperature was 200° C., and the thickness of the prepared perfluorosulfonic acid film doped with sulfonated graphene was 100 μm.

[0034] Th...

Embodiment 2

[0039] (1) 20wt% sulfonated graphene and 80wt% long-chain branched perfluorosulfonic acid resin are mixed uniformly in proportion, and then melted and extruded by a twin-screw extruder to obtain sulfonated graphene doping after granulation Perfluorosulfonic acid resin masterbatch, melt processing temperature is 200 ℃. The number of layers of the sulfonated graphene is 5 layers, the radial dimension is 500nm, the thickness is 20nm, and the S element content is 6wt%.

[0040] (2) The 20wt% sulfonated graphene-doped perfluorosulfonic acid resin masterbatch prepared in step (1) is mixed in proportion with the long-chain branched perfluorosulfonic acid resin of 80wt%, and then extruded by twin-screw The machine was melt-extruded to form a film to obtain a perfluorosulfonic acid film doped with sulfonated graphene. The melting processing temperature was 200° C., and the thickness of the prepared perfluorosulfonic acid film doped with sulfonated graphene was 100 μm.

[0041] The EW ...

Embodiment 3

[0046] (1) 10wt% sulfonated graphene and 90wt% long-chain branched perfluorosulfonic acid resin are mixed uniformly in proportion, and then melted and extruded by a twin-screw extruder to obtain sulfonated graphene doping after granulation Perfluorosulfonic acid resin masterbatch, the melt processing temperature is 250°C. The number of layers of the sulfonated graphene is 7 layers, the radial dimension is 1 μm, the thickness is 20 nm, and the S element content is 6 wt%.

[0047] (2) The 10wt% sulfonated graphene-doped perfluorosulfonic acid resin masterbatch prepared in step (1) is mixed in proportion with the long-chain branched perfluorosulfonic acid resin of 90wt%, and then extruded by twin-screw The machine was melted and extruded to form a film to obtain a perfluorosulfonic acid film doped with sulfonated graphene. The melting processing temperature was 250° C., and the thickness of the prepared perfluorosulfonic acid film doped with sulfonated graphene was 150 μm.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com