Epoxy resin adhesive for electronic devices and preparation method thereof

A technology for epoxy resin glue and electronic devices, which is applied in the direction of epoxy resin glue, novolac epoxy resin adhesive, adhesive, etc. Problems such as low degree of cross-linking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] An epoxy resin glue for electronic devices, the epoxy resin glue includes A component and B component, wherein A component is 25 parts of composite ionic liquid curing agent; B component is: 65 parts of epoxy resin;

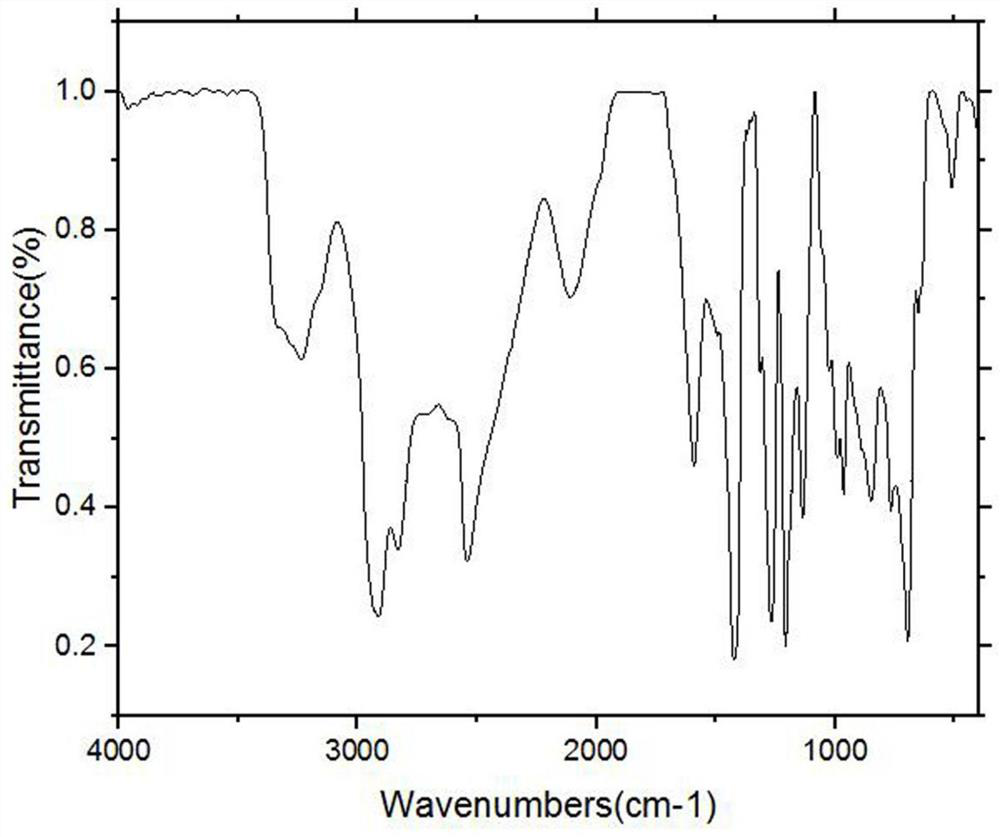

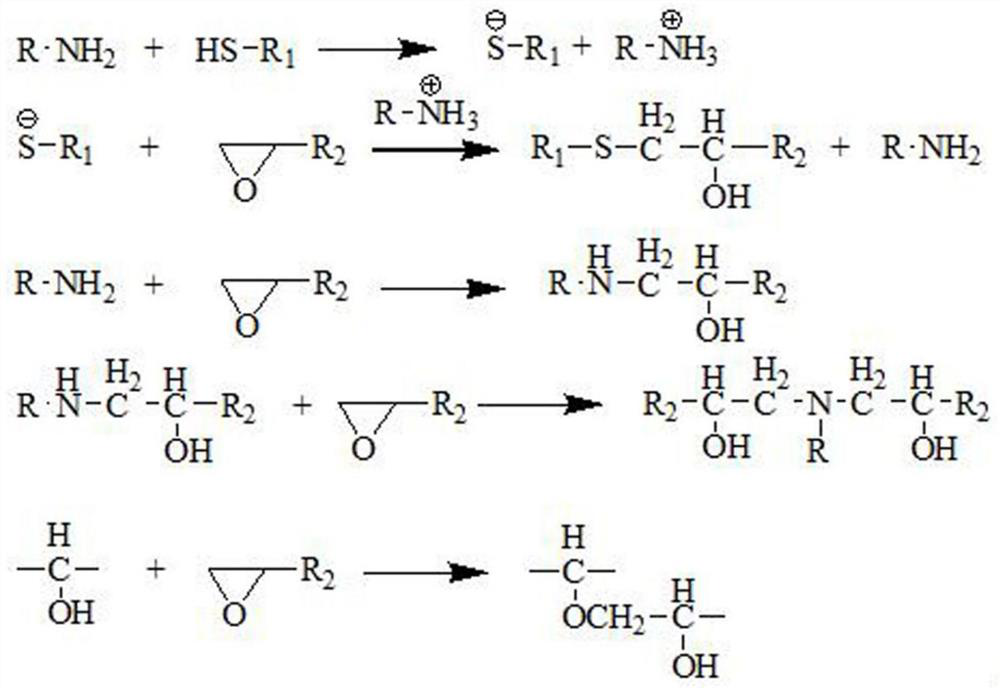

[0029] The preparation method of the composite ionic liquid curing agent is: weigh 2,3-(dimercaptoethyl)-1-propanethiol, amine compounds and imidazole ionic liquids at a mass ratio of 1:1:1, and °C, mechanically stirred for 24 hours to obtain a uniform and stable composite ionic liquid curing agent.

[0030] Described amine compound is dimethyl benzyl amine.

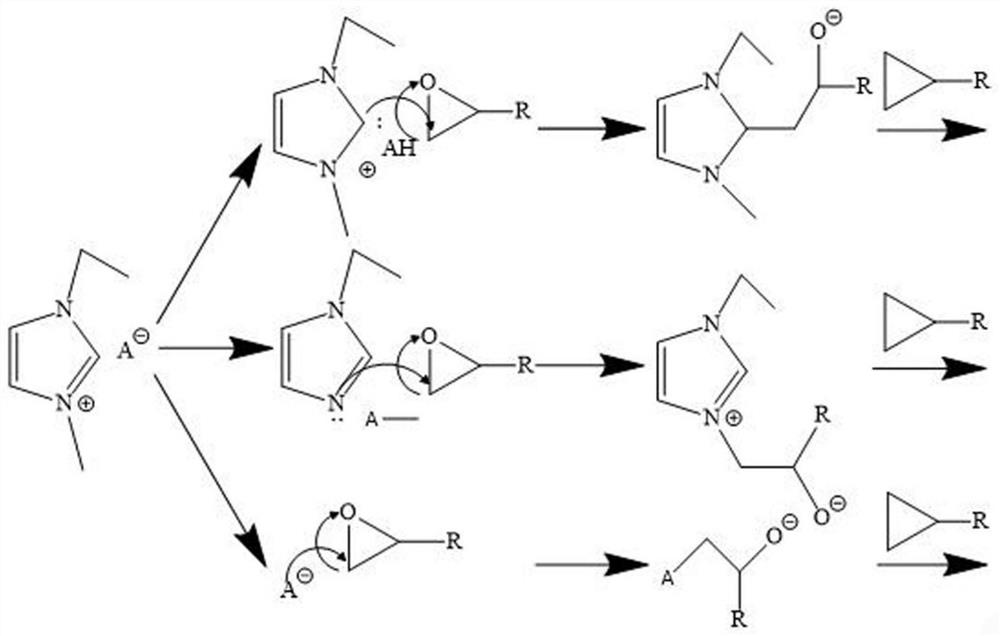

[0031] The imidazole ionic liquid is 1-ethyl-3-methylimidazole diethyl phosphate.

[0032] The 2,3-dithio(2-mercapto)-1-propanethiol is prepared from 1,3-bis(2-hydroxyethylthio)-2-propanol as a raw material through thiourea hydrochloride method and amine hydrolysis method Obtained, colorless and transparent, with an average molecular mass of 260.53.

[0033] The epoxy resin is novolac epoxy resin....

Embodiment 2

[0039] An epoxy resin glue for electronic devices, the epoxy resin glue includes A component and B component, wherein A component is 25 parts of composite ionic liquid curing agent; B component is: 69.5 parts of epoxy resin, accelerator 2 parts, 2 parts of thinner, 0.5 parts of plasticizer and 1 part of filler;

[0040] The preparation method of the composite ionic liquid curing agent is: weigh 2,3-(dimercaptoethyl)-1-propanethiol, amine compounds and imidazole ionic liquids at a mass ratio of 3:1:1, °C, mechanically stirred for 48 hours to obtain a uniform and stable composite ionic liquid curing agent.

[0041] The amine compound is triethylamine.

[0042] The imidazole ionic liquid is obtained by mixing 1-ethyl-3-methylimidazole acetate and 1-ethyl-3-methylthiocyanate according to a mass ratio of 1:1.

[0043] The 2,3-dithio(2-mercapto)-1-propanethiol is prepared from 1,3-bis(2-hydroxyethylthio)-2-propanol as a raw material through thiourea hydrochloride method and amine hy...

Embodiment 3

[0053] An epoxy resin glue for electronic devices, the epoxy resin glue includes A component and B component, wherein A component is 28 parts of composite ionic liquid curing agent; B component is: 74 parts of epoxy resin, accelerator 0.5 parts, 0.5 parts of diluent, 1 part of plasticizer and 1 part of filler;

[0054] The preparation method of the composite ionic liquid curing agent is: weigh 2,3-(dimercaptoethyl)-1-propanethiol, amine compounds and imidazole ionic liquids at a mass ratio of 6:1:1, °C, mechanically stirred for 36 hours to obtain a uniform and stable composite ionic liquid curing agent.

[0055] The amine compound is diethylenetriamine.

[0056] The imidazole ionic liquid is 1-ethyl-3-methylimidazole acetate.

[0057] The 2,3-dithio(2-mercapto)-1-propanethiol is prepared from 1,3-bis(2-hydroxyethylthio)-2-propanol as a raw material through thiourea hydrochloride method and amine hydrolysis method Obtained, colorless and transparent, with an average molecula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com