Large-size graphene foam board

A graphene foam, large-scale technology, applied in the direction of sheet/plate, thin plate connection, closing, etc., can solve the problems of forming a whole, increasing the transportation quality, and loosening the fixed place of the foam plate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

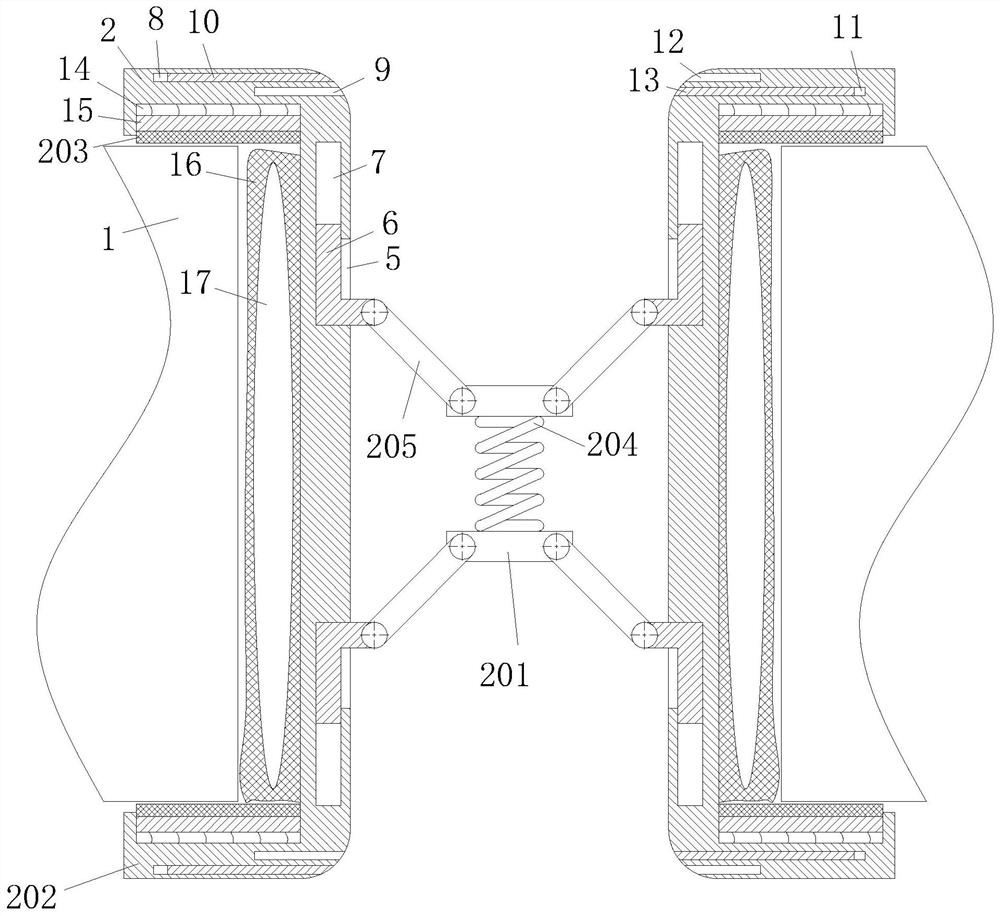

[0024] As an embodiment of the present invention, the upper and lower inner walls of the splint 202 are provided with a clamping groove 14; the clamping groove 14 is slidingly connected with a clamping block 15; the clamping block 15 is connected to the inner wall of the clamping groove 14 Evenly arranged pull ropes are fixed between them; the clamping groove 14 communicates with the corresponding extrusion chamber 7 through the air passage; when working, part of the gas in the extrusion chamber 7 enters the clamping groove when the foam boards 1 are approaching each other 14, so that the two clamping blocks 15 on the same base plate 202 slide relatively to realize further clamping and fixing of the foam board 1, further improve the sealing performance between the multi-layer foam boards 1, and improve the same layer of foam board 1 at the same time. The strength of the connection between them improves the safety of transportation and further reduces the consumption of manpower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com