Ga2O3 nanowire array film and preparation method thereof

A nanowire array, nanowire technology, applied in nanotechnology, nanotechnology, nanotechnology for sensing, etc., can solve the problems of high cost and short length of gallium oxide nanowire array

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

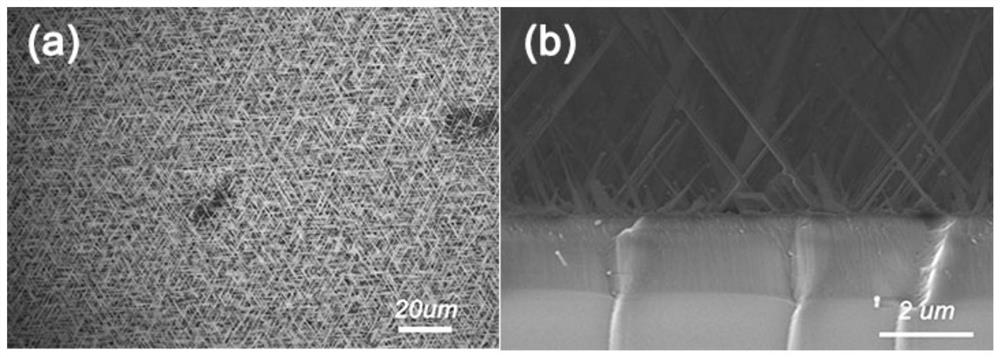

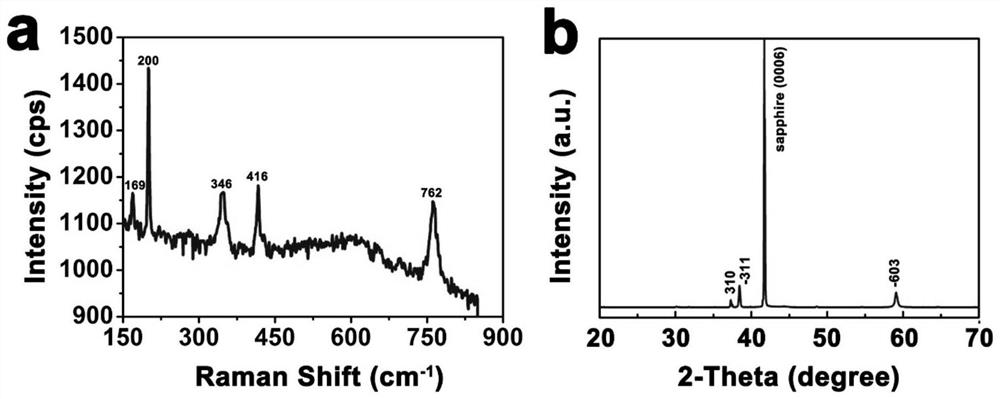

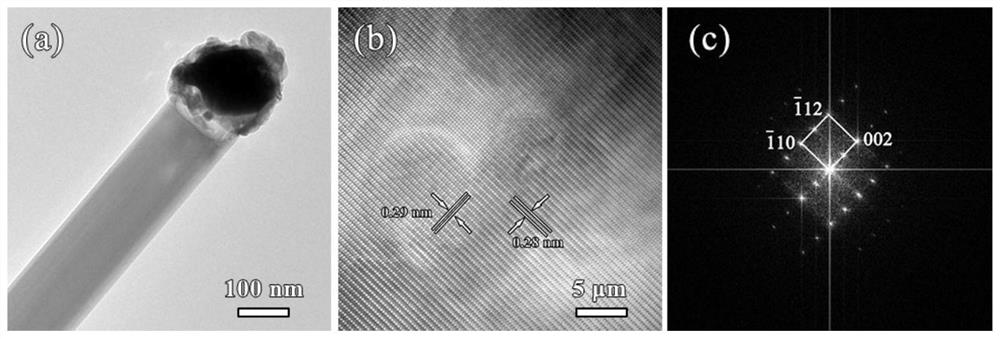

[0034] Such as Figure 4 As shown, this embodiment Ga 2 O 3 The preparation method of the nanowire array film is as follows:

[0035] 1. Weigh 0.2g of metal gallium 3 and place it in the corundum boat 2.

[0036] 2. Follow Figure 4 Arrangement: Transfer the corundum boat 2 in step 1 to the quartz tube 1. The diameter of the quartz tube 1 used is Φ20mm. Then the quartz tube 1 is placed in a tube furnace with three temperature zones (upper temperature zone, middle temperature zone, and lower temperature zone), and the corundum boat 2 is located in the heating center of the middle temperature zone.

[0037] 3. Place the quartz plate 4 with the gold-sprayed sapphire substrate 5 behind the corundum boat 2 in the quartz tube 1, and the distance between the substrate material and the metal gallium 3 is 4 cm. The gold-sprayed sapphire substrate 5 is located in the lower temperature zone of the three-temperature zone tube furnace, and its function is to provide nucleation sites with low n...

Embodiment 2

[0044] Such as Figure 4 As shown, this embodiment Ga 2 O 3 The preparation method of the nanowire array film is as follows:

[0045] 1. Weigh 0.5g of gallium metal 3 and place it in the corundum boat 2.

[0046] 2. Follow Figure 4 Arrangement: Transfer the corundum boat 2 in step 1 to the quartz tube 1. The diameter of the quartz tube 1 used is Φ25mm. Then the quartz tube 1 is placed in the heating center of the middle temperature zone of the three-temperature zone tube furnace.

[0047] 3. Place the quartz plate 4 on which the gold-sprayed sapphire substrate 5 is placed behind the corundum boat 2 in the quartz tube 1, and the distance between the substrate material and the metal gallium 3 is 3 cm. The position of the gold-sprayed sapphire substrate 5 is in the lower temperature zone of the three-temperature zone tube furnace, and its function is to provide nucleation sites with low nucleation energy for the growth of gallium oxide nanowires. The thickness of the sprayed gold l...

Embodiment 3

[0054] Such as Figure 4 As shown, this embodiment Ga 2 O 3 The preparation method of the nanowire array film is as follows:

[0055] 1. Weigh 0.3 g of gallium metal 3 and place it in the corundum boat 2.

[0056] 2. Follow Figure 4 Arrangement: Transfer the corundum boat 2 in step 1 to the quartz tube 1. The diameter of the quartz tube 1 used is Φ15mm. Then the quartz tube 1 is placed in the heating center of the middle temperature zone of the three-temperature zone tube furnace.

[0057] 3. Place the quartz plate 4 with the gold-sprayed sapphire substrate 5 behind the corundum boat 2 in the quartz tube 1, and the distance between the substrate material and the metal gallium 3 is 5 cm. The position of the gold-sprayed sapphire substrate 5 is in the lower temperature zone of the three-temperature zone tube furnace, and its function is to provide nucleation sites with low nucleation energy for the growth of gallium oxide nanowires. The thickness of the sprayed gold layer is 4nm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com