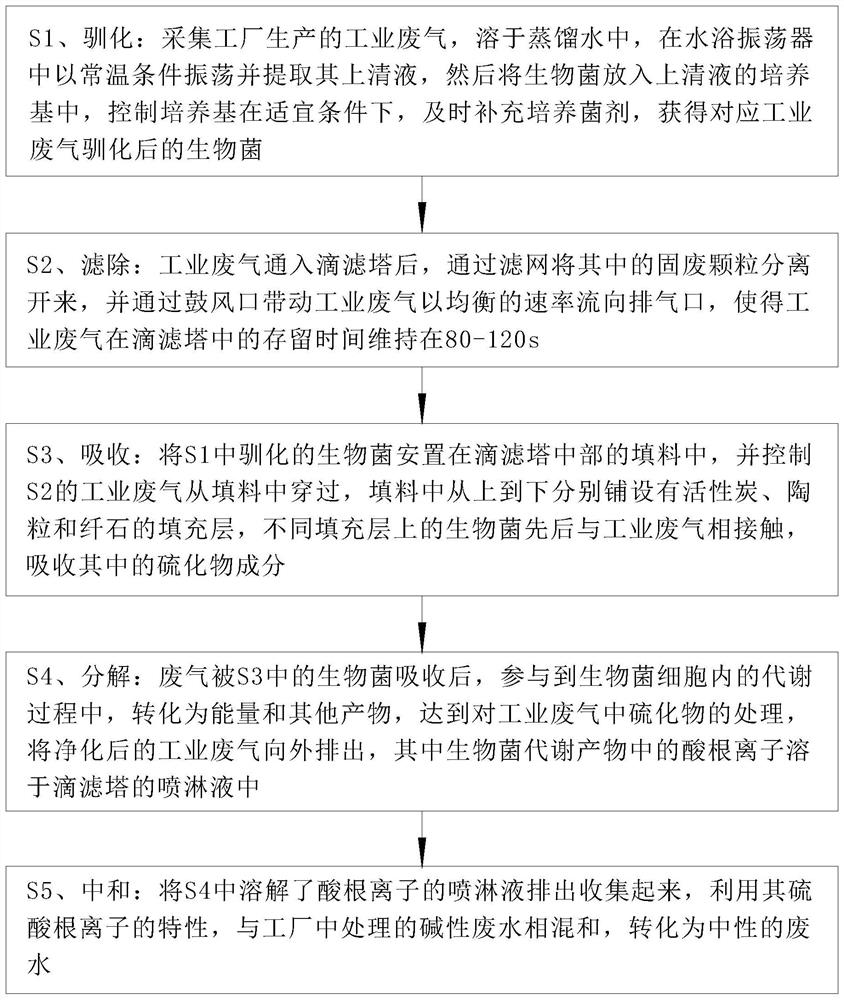

Sulfide purification treatment method for industrial waste gas

A technology for industrial waste gas purification and treatment, which is applied in gas treatment, chemical instruments and methods, separation methods, etc. It can solve the problems of large demand for desulfurization solutions, difficulty in ensuring sufficient contact and absorption of sulfide, and increase in air pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

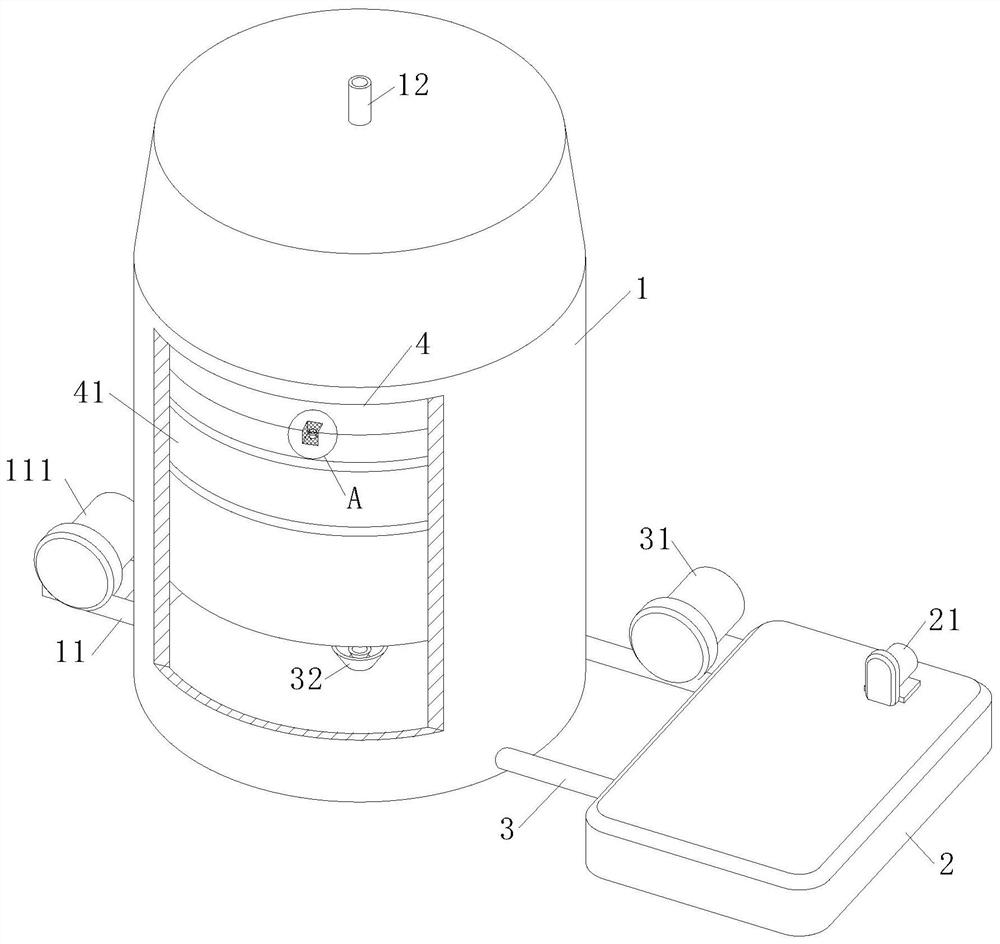

Examples

Embodiment approach

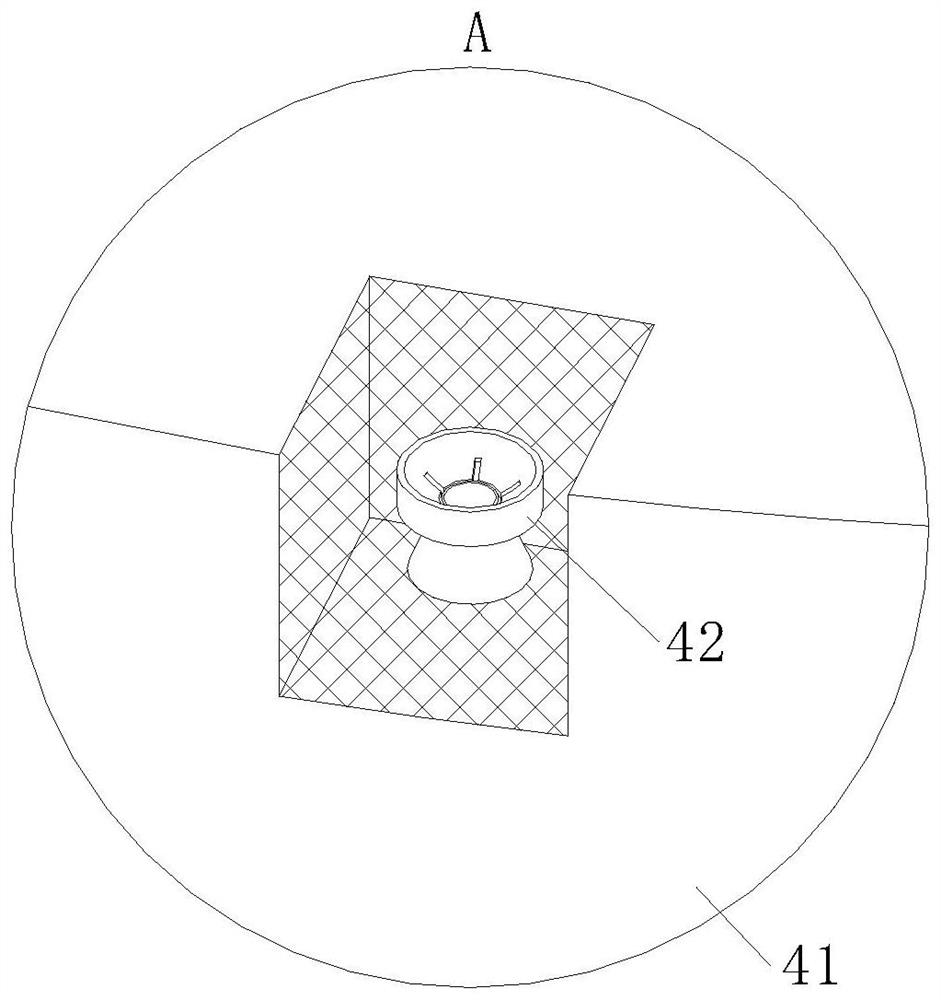

[0038] As an embodiment of the present invention, a cone 43 is arranged below the air flow hole 422, and the cone 43 is fixed on the lower surface of the bracket 42; the top of the cone 43 is provided with an opening 431, and the cone 43 The opening 431 of 43 extends into the airflow hole 422; after the biological bacteria absorb sulfide and metabolize, the acidic substance in the product will flow down along the airflow hole in the bracket 42 along with the bacterial agent replenished in the packing layer 4 422 flows out and interferes with the industrial waste gas flow rising in the air flow hole 422, destroying the contact between the sulfide in the industrial waste gas and the filler; through the cone 43 arranged below the flow hole 422, the opening on the top of the cone 43 431 allows the airflow to flow from it to the filler, and the top of the cone 43 extends into the air hole 422, so that the bacterial agent containing acidic substances flows down from the surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com