Ethyl cellulose composite membrane, preparation method and application thereof

A technology of ethyl cellulose and composite membrane, applied in chemical instruments and methods, membrane, membrane technology, etc., can solve the problems of peculiar smell, poor film-forming property, production of toxic substances, etc., and achieve good chemical stability and good hydrophobicity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

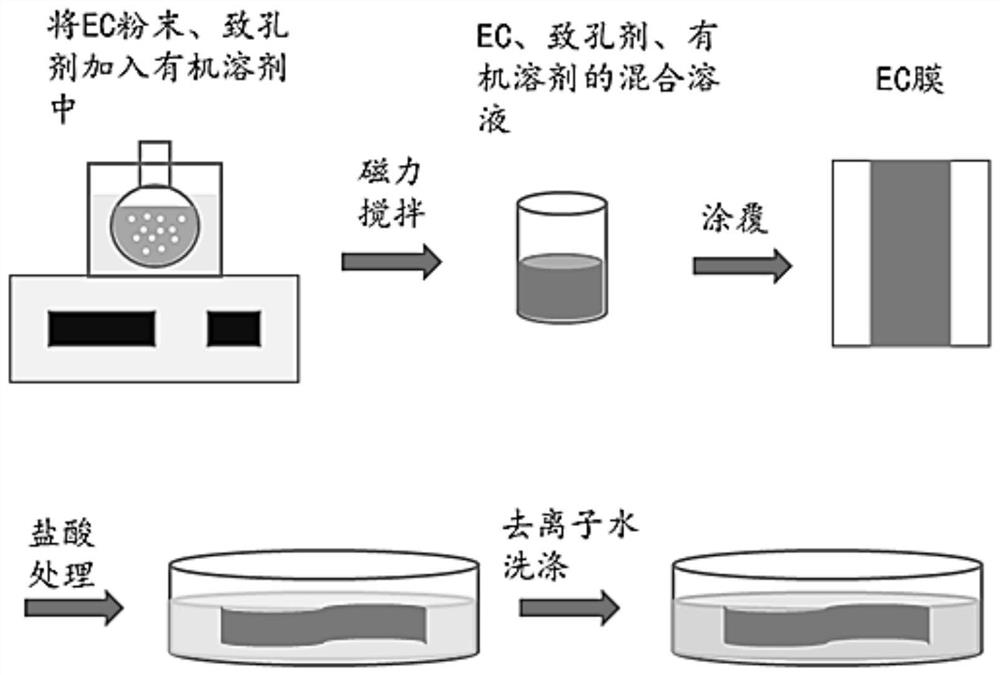

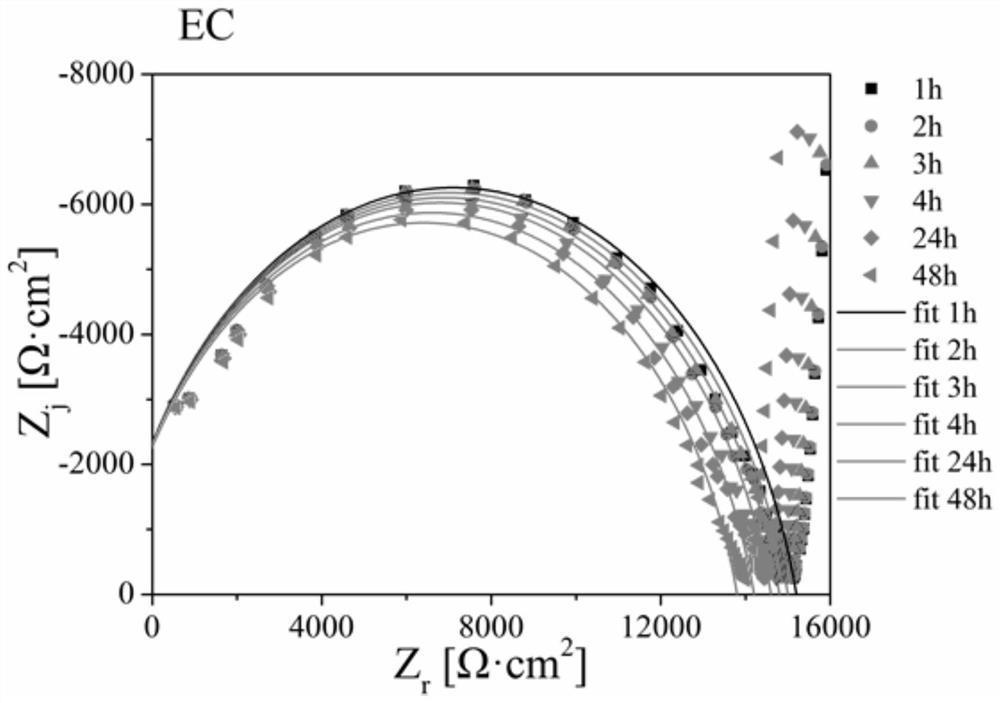

[0031] Take 2g of EC powder, add it to 10mL of ethanol solution, stir magnetically at 60°C for 6h, then evenly coat the stirred solution on a glass plate with a spatula, and soak the coated EC membrane in hydrochloric acid solution. The same group of samples were soaked in hydrochloric acid solution for 24 hours, and then soaked in deionized water for 24 hours to remove residual hydrochloric acid ions. After cleaning, the membrane was placed in the middle of a membrane cell equipped with a pair of Pt electrodes, and the impedance spectrum of the EC membrane was measured with an EIS device.

[0032] EIS equivalent circuit diagram:

[0033] Such as Figure 5 Shown is the EC membrane without adding porogen (RS means solution resistance, REC means EC membrane resistance, CPEEC means EC membrane capacitance).

[0034] Such as Figure 6 Shown is the EC composite membrane with porogen added (RX represents the resistance of the porogen, and CPEX represents the capacitance of the po...

Embodiment 2

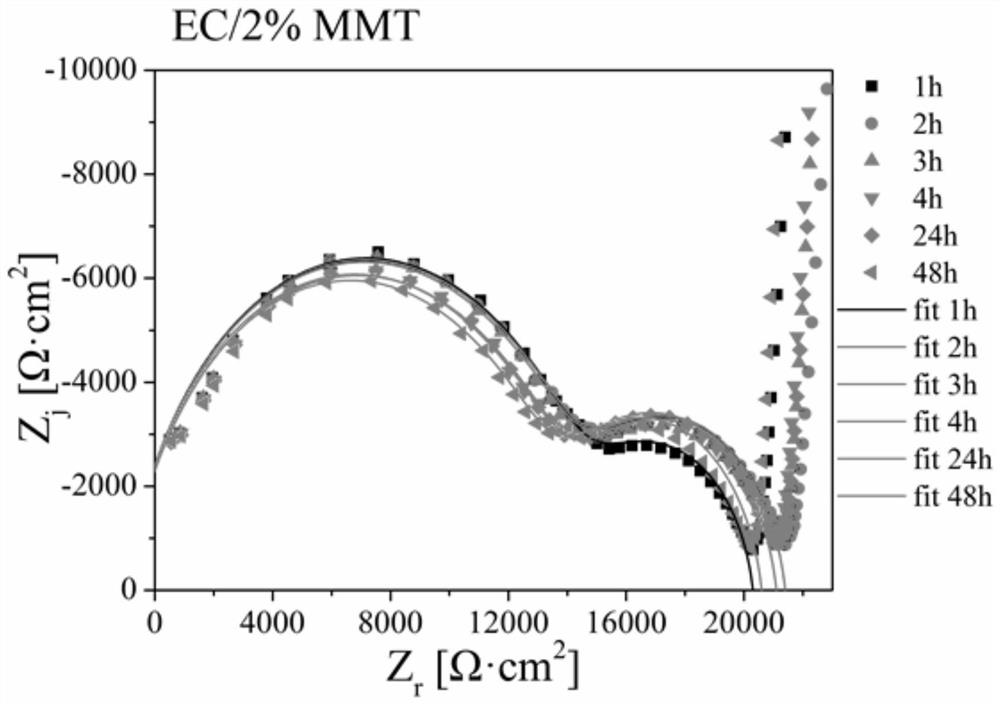

[0038] Use dimethyl sulfoxide (DMSO) to perform intercalation reaction on Na-MMT powder to obtain exfoliated MMT powder. Take 2 g of EC powder and add MMT powder (concentration 2%) to 10 mL of ethanol solution, and stir magnetically at 60 ° C. 6h, then the stirred solution was uniformly coated on a glass plate with a spatula, and then the coated EC composite membrane was soaked in hydrochloric acid solution. The same group of samples were soaked in hydrochloric acid solution for 24 hours, and then soaked in deionized water for 24 hours to remove residual hydrochloric acid ions. After cleaning, the membrane was placed in the middle of a membrane cell equipped with a pair of Pt electrodes, and the impedance spectrum of the EC composite membrane was measured with an EIS device.

[0039] Such as image 3 As shown, compared with the EC composite film without adding MMT powder, the impedance value of the EC composite film mixed with MMT powder stabilized at a higher value. The res...

Embodiment 3

[0041] Use dimethyl sulfoxide (DMSO) to perform intercalation reaction on Na-MMT powder to obtain exfoliated MMT powder. Take 2g of EC powder and add MMT powder (concentration 5%) to 10mL ethanol solution, and stir magnetically at 60°C 6h, then the stirred solution was uniformly coated on a glass plate with a spatula, and then the coated EC composite membrane was soaked in hydrochloric acid solution. The same group of samples were soaked in hydrochloric acid solution for 24 hours, and then soaked in deionized water for 24 hours to remove residual hydrochloric acid ions. After cleaning, the membrane was placed in the middle of a membrane cell equipped with a pair of Pt electrodes, and the impedance spectrum of the EC composite membrane was measured with an EIS device.

[0042] Such as Figure 4 As shown, compared with the EC composite film without adding MMT powder, the impedance value of the EC composite film mixed with MMT powder stabilized at a higher value. The results sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com