A kind of preparation method of demetallization catalyst

A catalyst and demetallization technology, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, chemical instruments and methods, etc., can solve the problem that the pore volume of the catalyst needs to be further improved, so as to facilitate mass transfer and diffusion, reduce production costs, and reduce environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

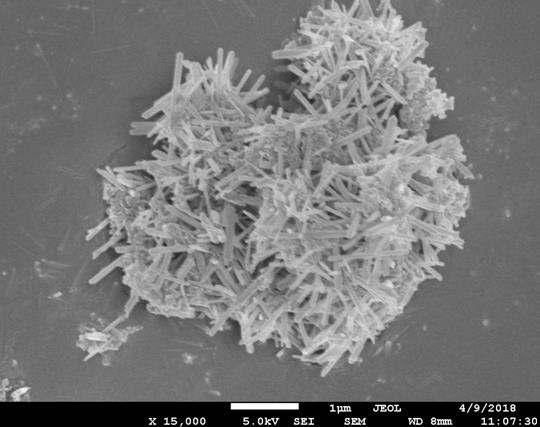

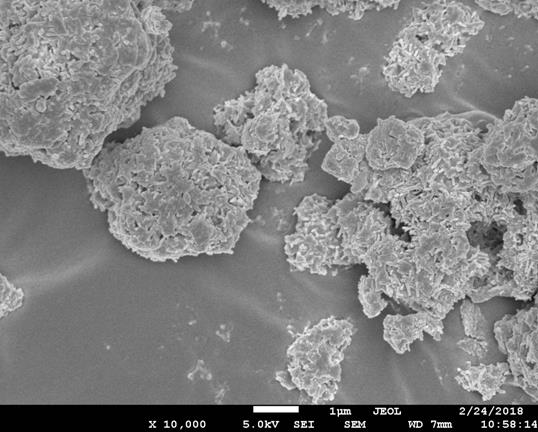

[0035] (1) Take the waste catalyst pulverized to more than 230 mesh and roast it at 750 °C for 8 hours;

[0036] (2) Weigh the above waste catalyst 50 grams placed in 300 grams of mass percentage concentration of 18% ammonium bicarbonate aqueous solution, the mixed material into an autoclave seal heat treatment, heat treatment conditions: 140 °C heating for 6 hours, and then the powder at 110 °C drying for 6 hours. With a mass percentage concentration of 25% polyethylene glycol-6000 (i.e., molecular weight of 6000) solution soaked for 1.5 hours, filtered, dried at 120 °C for 6 hours, to prepare pretreatment material A;

[0037] (3) Weigh 100 grams of pseudo-thin bauxite, pretreated material A 30 grams, Tian Jing powder 1.5 grams, mix the above physics evenly, add an appropriate amount of aqueous solution dissolved in 3 grams of acetic acid to knead, extrude molding, the mold was dried at 140 °C for 6 hours, 700 °C was roasted in air for 5 hours, and the carrier was prepared with M...

Embodiment 2

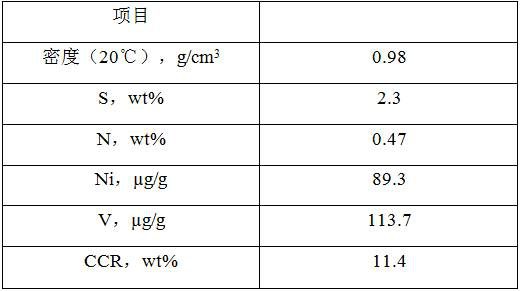

[0039] As in Example 1, only the mass percentage concentration of ammonium bicarbonate is 21%, the heat treatment temperature is 120 ° C, the heat treatment time is 8 hours, and polyethylene glycol -2000 (i.e., the molecular weight is 2000) solution, the mass percentage concentration is 30%. The amount of pretreated material A was 45 grams, and the catalyst Cat-2 was prepared, and the properties of the catalyst were shown in Table 1.

Embodiment 3

[0041]As in Example 1, the roasting temperature of the waste catalyst powder is 900 ° C. The mass percentage concentration of ammonium bicarbonate solution is 15%, the heat treatment temperature is 160 °C, the heat treatment time is 4 hours, and the polyethylene glycol-12000 (that is, molecular weight is 12000) solution is switched to a mass percentage concentration of 20%. The pretreatment material A was added in an amount of 20 grams to obtain cat-3 catalyst, and the properties of the catalyst were shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com