A carbon nitride/tungsten trioxide two-dimensional composite z-type photocatalytic material, preparation method and application

A technology of photocatalytic materials and tungsten trioxide, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve undiscovered problems and achieve easy availability of raw materials, high redox ability, large The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation method is as follows:

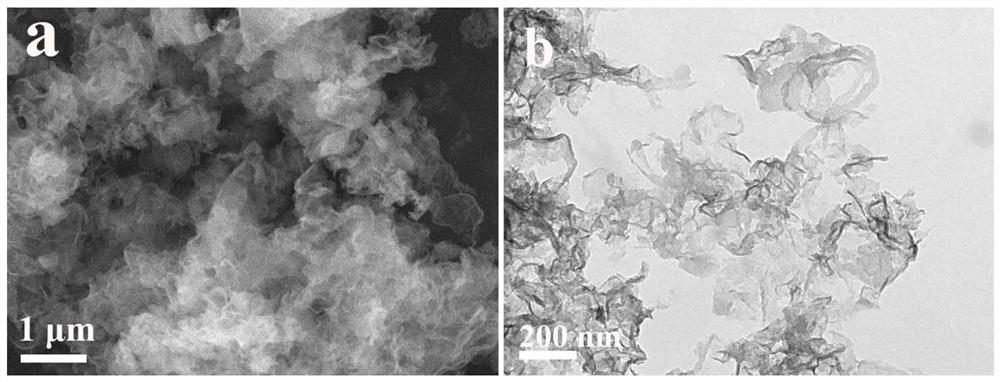

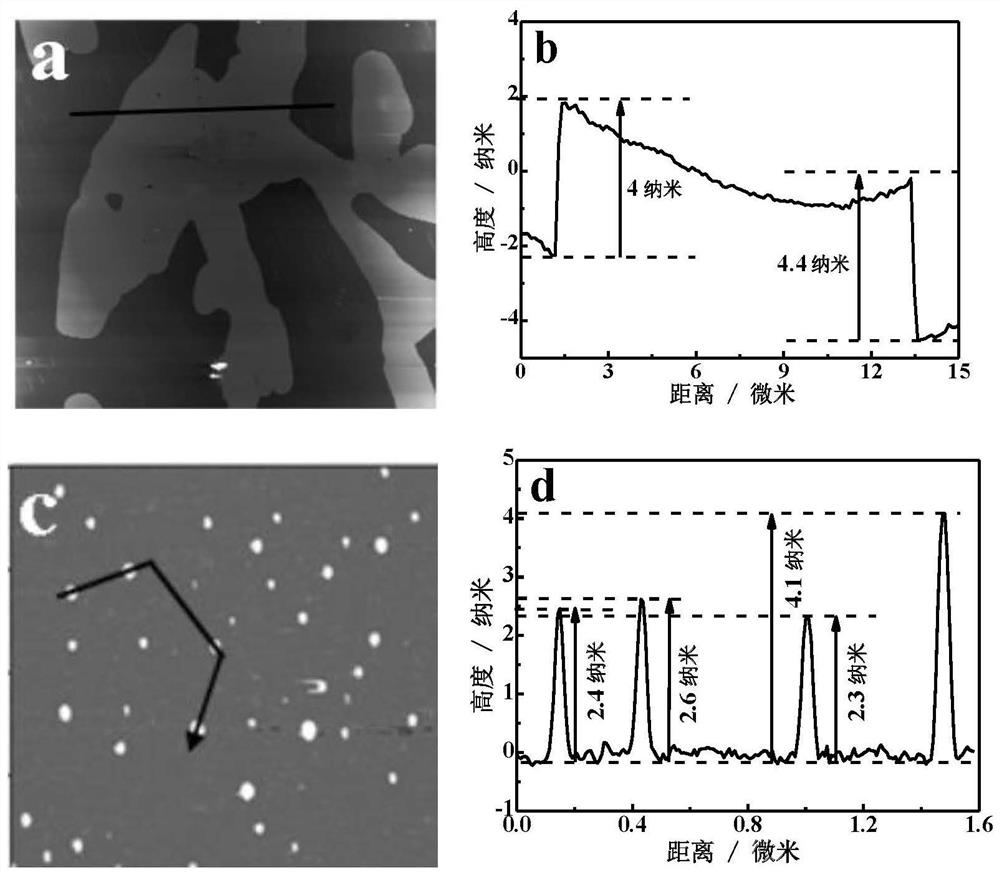

[0043] (1) Add 12g of urea into a 50mL porcelain crucible, 550°C, 5°C·min -1 Calcined for 2h under the condition of heating rate, and ground to obtain g-C 3 N 4 powder; take 50 mg of the powder in a porcelain boat, and then at 520 ° C, 5 ° C min -1 Calcined for 3 hours under the condition of heating rate to obtain ultra-thin carbon nitride (CN / NS);

[0044] (2) The ultra-thin product is dispersed in 40mL deionized water and 15mL methanol solution, and then an appropriate amount of 0.08mol L -1 H 2 PtCl 6 Solution, ultrasonically dispersed for 5 minutes, the above suspension was irradiated under a high-pressure mercury lamp for 3 hours, centrifuged, washed, and dried to obtain 1 wt% Pt-loaded carbon nitride (Pt-CN / NS);

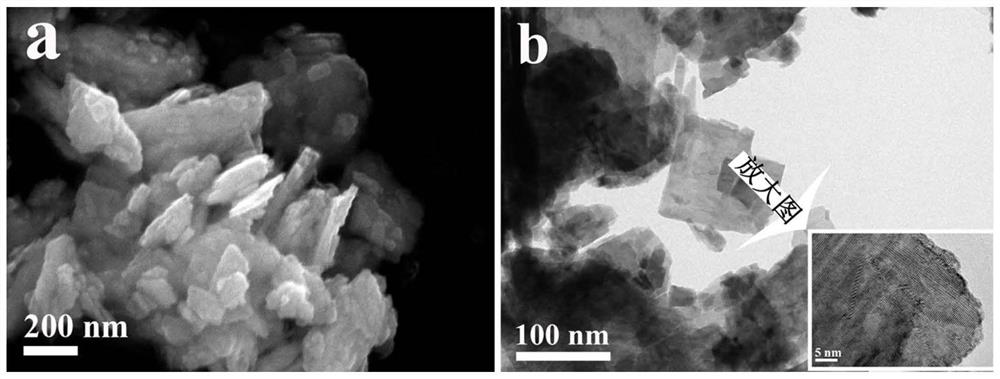

[0045] (3) Take 0.5000g of Na 2 WO 4 2H 2 O was dissolved in 60 mL of deionized water, and then 22 mL of HCl solution (3.0 M) was added dropwise with stirring to obtain a light yellow floc, and 0.4500 g of...

Embodiment 2

[0051] (1) Add 12g of urea into a 50mL porcelain crucible, 550°C, 5°C·min -1 Calcined for 2h under the condition of heating rate, and ground to obtain g-C 3 N 4 powder; take 50mg of the powder in a porcelain boat, and then at 520 ° C, 5 ° C min -1 Calcined for 3 hours under the condition of heating rate to obtain ultra-thin carbon nitride (CN / NS);

[0052] (2) The ultra-thin product is dispersed in 40mL deionized water and 15mL methanol solution, and then an appropriate amount of 0.08mol L -1 H 2 PtCl 6 Solution, ultrasonically dispersed for 5 minutes, the above suspension was irradiated under a high-pressure mercury lamp for 3 hours, centrifuged, washed, and dried to obtain 1 wt% Pt-loaded carbon nitride (Pt-CN / NS);

[0053] (3) Take 0.5000g of Na 2 WO 4 2H 2 O was dissolved in 60 mL of deionized water, and then 22 mL of HCl solution (3.0 M) was added dropwise with stirring to obtain a light yellow floc, and 0.4500 g of (NH 4 ) 2 C 2 o 4 ·H 2 O, stir until the so...

Embodiment 3

[0056] (1) Add 12g of urea into a 50mL porcelain crucible, 550°C, 5°C·min -1 Calcined for 2h under the condition of heating rate, and ground to obtain g-C 3 N 4 powder; take 50mg of the powder in a porcelain boat, and then at 520 ° C, 5 ° C min -1 Calcined for 3 hours under the condition of heating rate to obtain ultra-thin carbon nitride (CN / NS);

[0057] (2) The thin product is dispersed in 40mL deionized water and 15mL methanol solution, and then add an appropriate amount of 0.08mol L -1 H 2 PtCl 6 Solution, ultrasonically dispersed for 5 minutes, the above suspension was irradiated under a high-pressure mercury lamp for 3 hours, centrifuged, washed, and dried to obtain 1 wt% Pt-loaded carbon nitride (Pt-CN / NS);

[0058] (3) Take 0.5000g of Na 2 WO 4 2H 2 O was dissolved in 60 mL of deionized water, and then 22 mL of HCl solution (3.0 M) was added dropwise with stirring to obtain a light yellow floc, and 0.4500 g of (NH 4 ) 2 C 2 o 4 ·H 2 O, stir until the solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com