Composite cement-based material and composite cement-based material sensor

A technology of composite cement and base materials, applied in the field of composite cement-based materials and composite cement-based materials sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

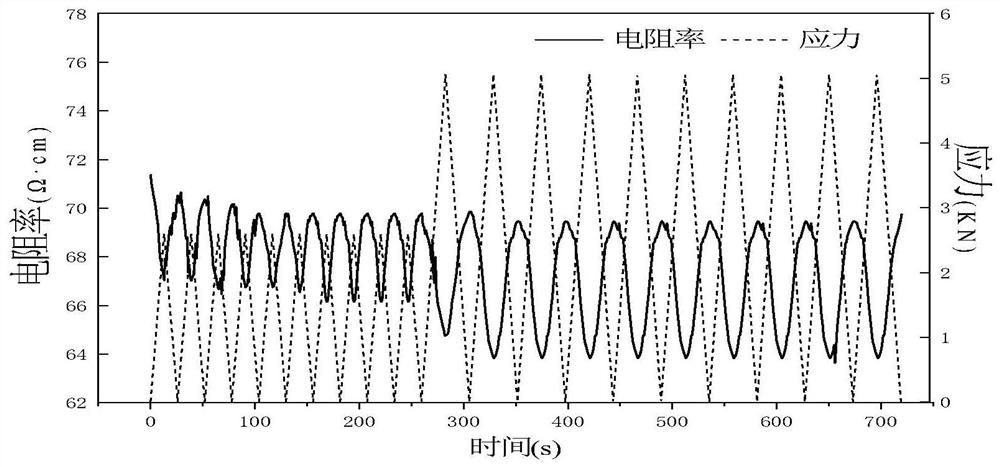

Embodiment 1

[0029] (1) Take by weighing 0.1g of multi-walled carbon nanotubes MWCNT, weigh 75mL mass fraction of 98% concentrated nitric acid and 25mL mass fraction of 68% concentrated sulfuric acid respectively, press concentrated nitric acid and concentrated sulfuric acid in a beaker for 3 The volume ratio of :1 is configured into a mixed acid solution, and the obtained mixed acid is added to a flat-bottomed flask equipped with carbon nanotubes, and the flask is continuously pulsed ultrasonically dispersed for 15 minutes under the condition of 600w with an ultrasonic disperser, and then the dispersed carbon nanotubes Put the tube into a magnetic stirrer for acid oxidation treatment at 80°C for 8 hours. After the acidification treatment, add deionized water to the flat-bottomed flask to dilute the acid solution, use a microporous membrane to filter under vacuum and reduce pressure, and use an evaporating dish to recover the acid oxidation. The final carbon nanotubes were washed repeatedly...

Embodiment 2

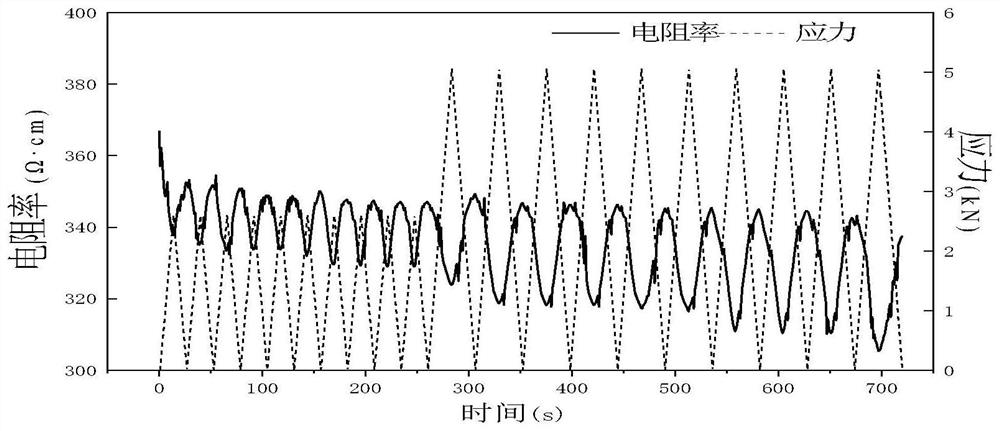

[0037] The basic steps are the same as in Example 1, except that in step (3), 0.012 g of carbon fiber is added to the reactor, and the reactor is put into an oven and reacted for 48 hours at 200 ° C; in step (5), carbon nanotubes are grafted The carbon fiber quality is 0.2% of the cement quality; in step (6), the dosage of the cerium oxide-graphene oxide composite material is 0.5% of the epoxy resin quality, and its thickness is 5mm.

Embodiment 3

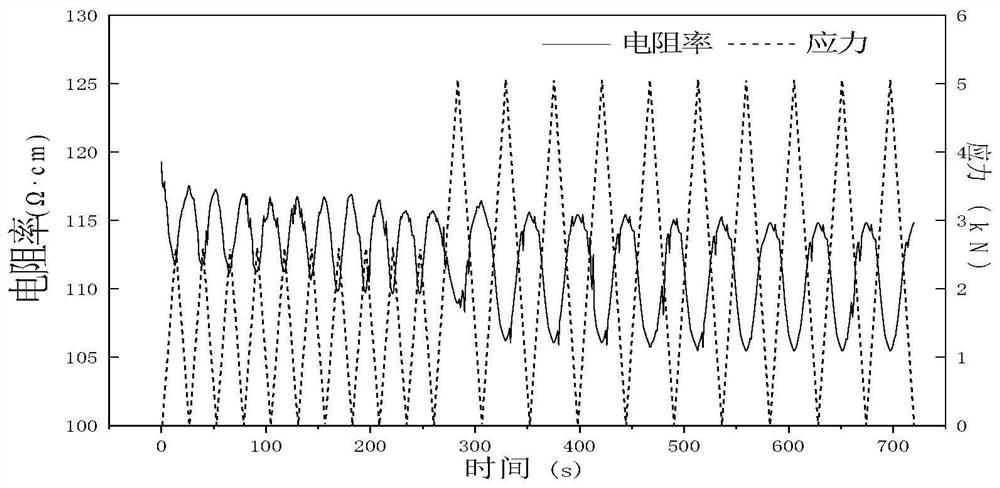

[0039]The basic steps are the same as in Example 1, except that in step (3), 0.01 g of carbon fiber is added to the reactor, and the reactor is put into an oven and reacted for 49 hours at 190° C.; in step (5), carbon nanotubes are grafted The carbon fiber quality is 0.6% of the cement quality; in step (6), the dosage of the cerium oxide-graphene oxide composite material is 0.7% of the epoxy resin quality, and its thickness is 7mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com