Preparation method of tert-butyl peroxybenzoate

A technology for tert-butyl peroxybenzoate and tert-butanol peroxide is applied in the field of preparation of tert-butyl peroxybenzoate, and can solve the problems of large amount of waste water, low impurity conversion rate, easy decomposition and deterioration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

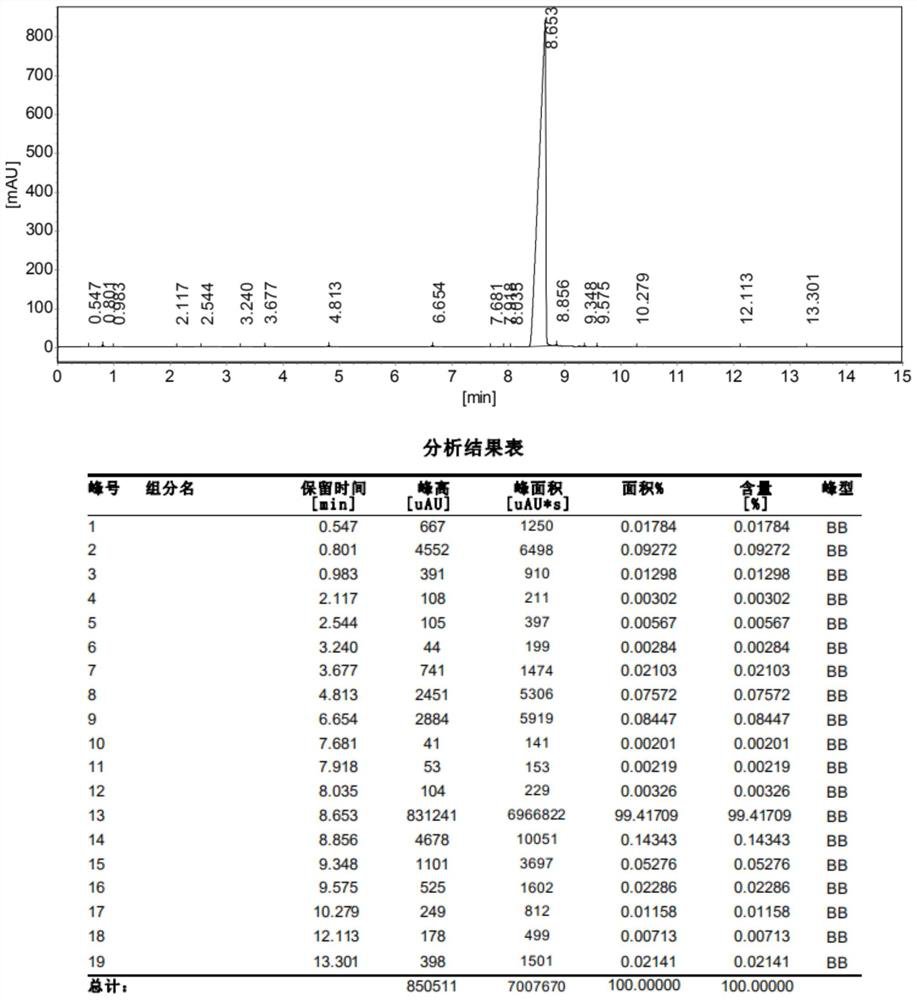

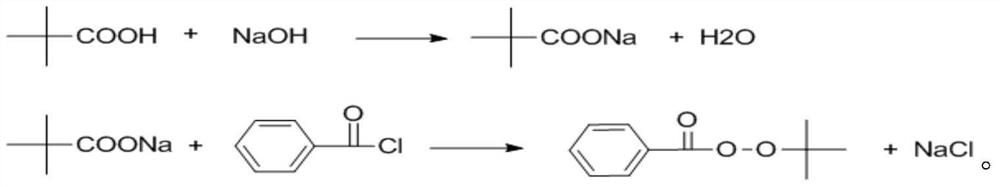

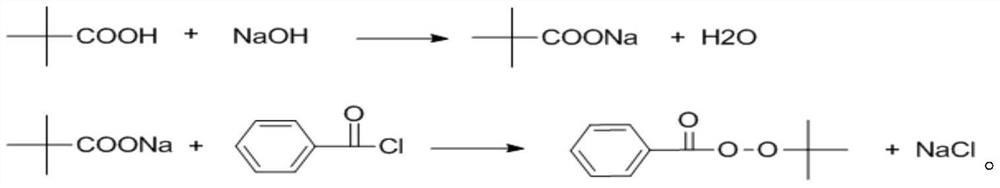

[0027] Embodiment 1: the preparation of tert-butyl peroxybenzoate

[0028] Add 144g of 5% sodium hydroxide (0.18mol) solution into the reaction flask, cool down to 5-10°C, slowly add 21.8g (0.15mol) of 70% tert-butanol peroxide dropwise, and the dropwise addition completes the reaction 1 hour; keep the temperature at 5-10°C and add 21g (0.15mol) benzoyl chloride dropwise, and keep stirring for 1 hour after the dropwise addition; after standing for 0.5 hours, separate the liquid, collect the high-salt wastewater in the lower layer for three-effect evaporation treatment, and the organic The phase was stirred and washed twice with 30ml / time of purified water; then the lower layer product was added with 0.2g of stabilizer and 1g of anhydrous magnesium sulfate, dried and suction filtered to obtain 28.5g of tert-butyl peroxybenzoate with a content of 99.4%. , yield 98.15%.

Embodiment 2

[0029] Embodiment 2: the preparation of tert-butyl peroxybenzoate

[0030] Add 45g of 8% sodium hydroxide (0.09mol) solution into the reaction flask, cool down to 10-15°C, slowly add 11.9g (0.075mol) of 70% tert-butanol peroxide dropwise, and the dropwise addition completes the reaction 1 hour; keep the temperature at 5-10°C and add 10.7g (0.077mol) benzoyl chloride dropwise, and keep stirring for 1 hour after the dropwise addition; after standing for 0.5 hours, separate the liquid, collect the high-salt wastewater in the lower layer for three-effect evaporation treatment, and the upper layer The organic phase is stirred and washed twice with 15ml / time of purified water; then the lower layer product is added with 0.1g of stabilizer and 0.5g of anhydrous magnesium sulfate, dried, and suction filtered to obtain tert-butyl peroxybenzoate with a content of 99.2%. 14.30 g, yield 98.22%.

Embodiment 3

[0031] Embodiment 3: the preparation of tert-butyl peroxybenzoate

[0032] Add 72g of 10% sodium hydroxide (0.18mol) solution into the reaction flask, cool down to 15-20°C, slowly add 23.2g (0.16mol) of 70% tert-butanol peroxide dropwise, and the dropwise addition completes the reaction 1 hour; keep the temperature at 10-15°C and add 24.7g (0.176mol) benzoyl chloride dropwise, and keep stirring for 1 hour after the dropwise addition; after standing for 0.5 hours, separate the liquid, collect the high-salt wastewater in the lower layer for three-effect evaporation treatment, and the upper layer The organic phase was stirred and washed twice with 30ml / time of purified water, and the lower layer product was added with 0.2g of stabilizer and 1g of anhydrous magnesium sulfate, dried, and suction filtered to obtain tert-butyl peroxybenzoate 30.4 with a content of 99.08%. g, yield 98.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com