Carbon-coated lithium supplementing material as well as preparation method and application thereof

A carbon coating and carbon coating layer technology is applied in the field of carbon coating lithium-replenishing materials and their preparation, which can solve the problems of affecting battery life, high decomposition potential of lithium-containing compounds, generation of oxygen and other by-products, etc. The effect of irreversible lithium loss, improving battery energy density, and reducing decomposition potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

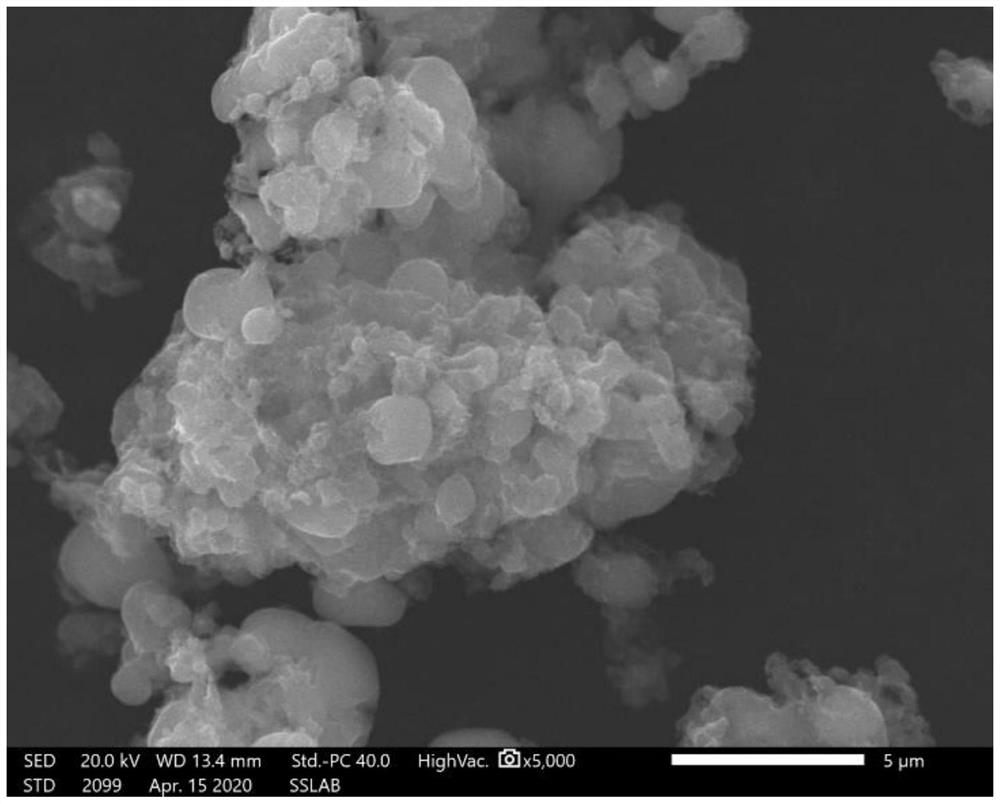

[0027] the SiO 2 and Li 2 CO 3 Mix and grind at a stoichiometric ratio of 1:2, and sinter at 800 °C to obtain Li 4 SiO 4 , as a lithium-containing compound, and then combined with the reducing agent CaB 6 Mixed at a weight ratio of 10:1, sintered at 800°C in a tube furnace, and fed with methane gas to prepare a carbon-coated lithium-replenishing material with a morphology as follows figure 1 shown in the scanning electron microscope photo.

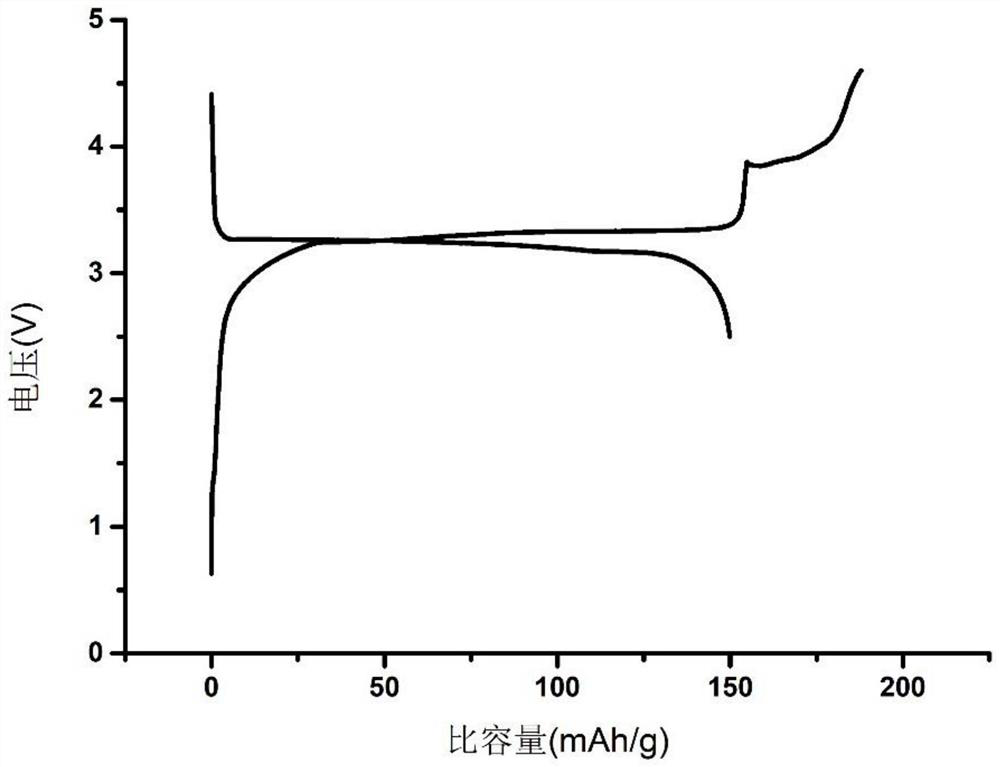

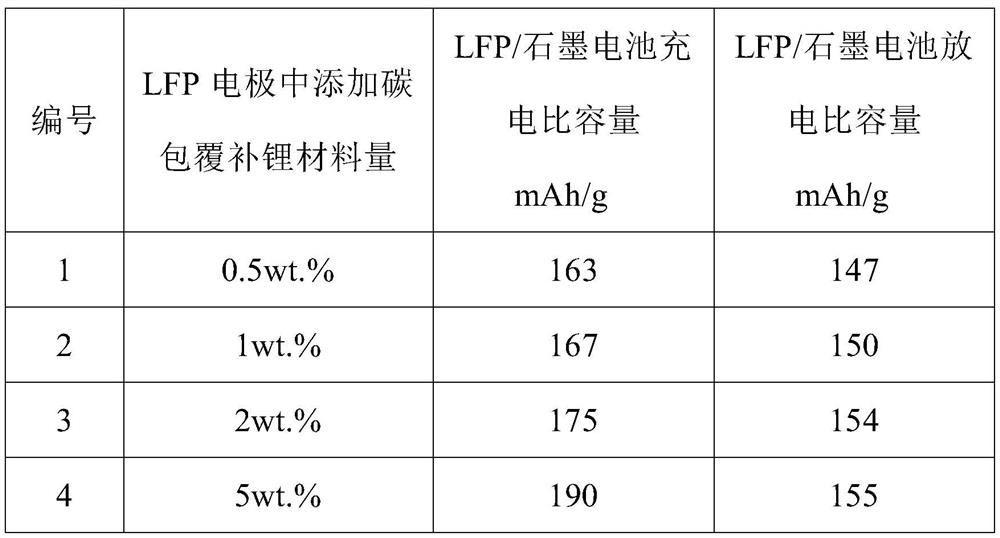

[0028] During the LFP electrode slurry mixing process, the above-mentioned carbon-coated lithium-replenishing material was added to make a positive electrode sheet, which was then assembled with a graphite negative electrode sheet to form a full battery for testing. The charging curve in the first week is as follows: figure 2 As shown in the figure, when charged to 4.5V, the lithium replenisher releases active lithium ions and exerts the lithium replenishment capacity. Different amounts of carbon-coated lithium-replenishing material...

Embodiment 2

[0032] Combining Lithium Oxide Powder with CaB 6 Mixing and grinding at a weight ratio of 10:1, then sintering at 800°C in a tube furnace, and feeding methane gas to prepare a carbon-coated lithium-replenishing material. During the LFP electrode slurry mixing process, 2wt.% of the above carbon-coated lithium-replenishing material was added to make a positive electrode sheet, which was then assembled with a graphite negative electrode sheet to form a full battery. The experimental test showed that the carbon-coated lithium-replenishing material during the first week of charging was It can actually supplement the active lithium for the battery.

Embodiment 3

[0034] Combining Lithium Oxide Powder with CaB 6 Mixed and ground at a weight ratio of 10:1, then sintered at 800°C in a tube furnace, and fed with methane gas to prepare a carbon-coated lithium supplement. In the process of NCM ternary electrode slurry mixing, 2wt.% of the above carbon-coated lithium-replenishing material was added to make a positive electrode sheet, which was then assembled with a graphite negative electrode sheet to form a full battery. The experimental test showed that the carbon-coated supplementary material during the first week of charging was Lithium materials can actually supplement active lithium for batteries.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com