Tubular film based on nuclear track film and application

A nuclear pore membrane, tubular membrane technology, applied in membrane technology, semi-permeable membrane separation, water/sludge/sewage treatment, etc. Difficulty in application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

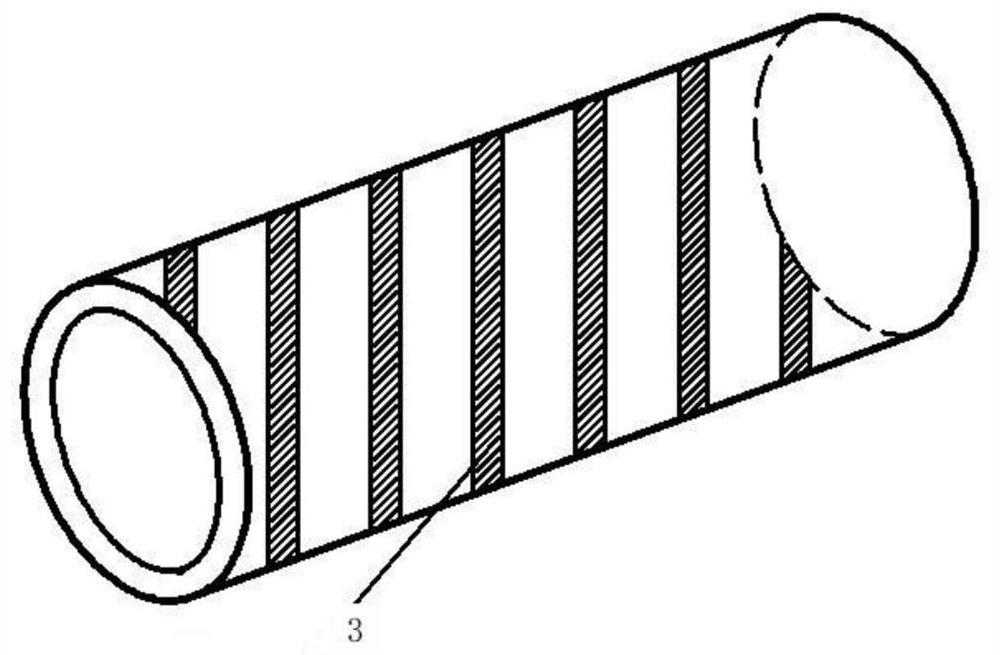

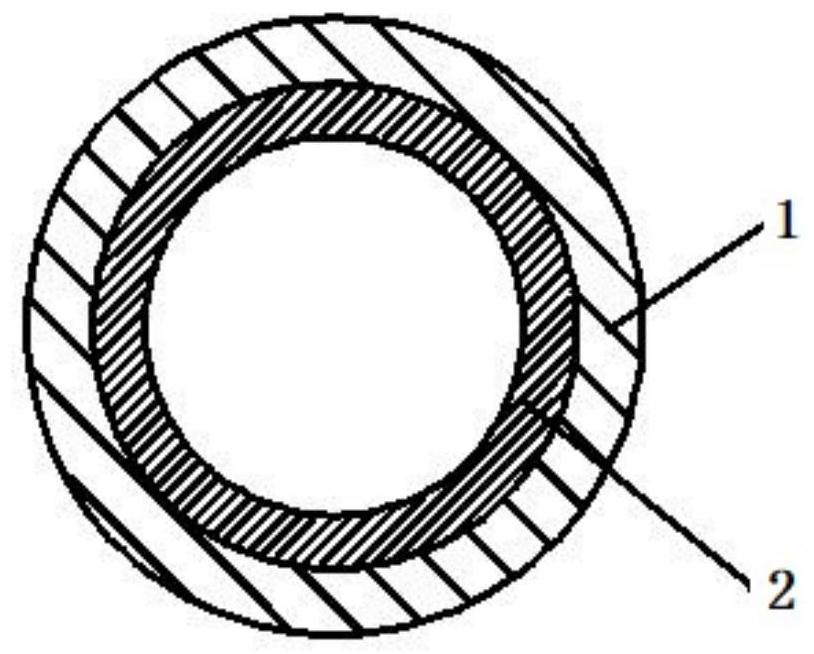

[0030]This embodiment provides a tubular membrane based on a nuclear pore membrane, including a composite material, the composite material is wound to form a tubular structure, the composite material includes a support layer and a nuclear pore membrane layer, and the support layer is PET Non-woven fabric, the nuclear pore membrane layer is hot-pressed and composited on the outside of the support layer, the nuclear pore membrane layer is distributed with channels for screening, and there are overlapping positions between adjacent composite materials. The width is 2 mm, and the composite material is rolled into a tubular tube film at 45°, and the superimposed parts are sealed by ultrasonic welding.

[0031] The material of the nuclear pore membrane layer is PET, the thickness of the nuclear pore membrane layer is 15 microns, the pore diameter is 15 microns, and the pore density is 2×10 5 pieces / square centimeter; the thickness of the support layer non-woven fabric is 50 microns,...

specific Embodiment 2

[0033] This embodiment provides a tubular membrane based on a nuclear pore membrane, including a composite material, the composite material is wound to form a tubular structure, the composite material includes a support layer and a nuclear pore membrane layer, and the support layer is PP Non-woven fabric, the nuclear pore membrane layer is hot-pressed and composited on the outside of the support layer, the nuclear pore membrane layer is distributed with channels for screening, and there are overlapping positions between adjacent composite materials. The width is 3 mm, and the composite material is rolled into a tubular tube film at 30°, and the superimposed parts are sealed by ultrasonic welding.

[0034] The material of the nuclear pore membrane layer is PP, the thickness of the nuclear pore membrane is 15 microns, the pore diameter is 15 microns, and the pore density is 2×105 per square centimeter; the thickness of the non-woven fabric is 150 microns, the pore diameter is 20 ...

specific Embodiment 3

[0036] This embodiment provides a tubular membrane based on a nuclear pore membrane, including a composite material, the composite material is wound to form a tubular structure, the composite material includes a support layer and a nuclear pore membrane layer, and the support layer is PP non-woven fabric, the nuclear pore membrane layer is hot-compressed on the inner and outer sides of the support layer, that is, the nuclear pore membrane layer is compounded on the inner and outer sides of the support layer, and the nuclear pore membrane layer is distributed with For the sieve channel, there is an overlapping position between adjacent composite materials, and the width of the overlapping position is 3 mm. The composite material is rolled into a cylindrical tubular film at 30°, and the overlapping position is sealed by ultrasonic welding.

[0037] The material of the nuclear pore membrane layer is PP, the thickness of the nuclear pore membrane is 15 microns, the pore diameter is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com