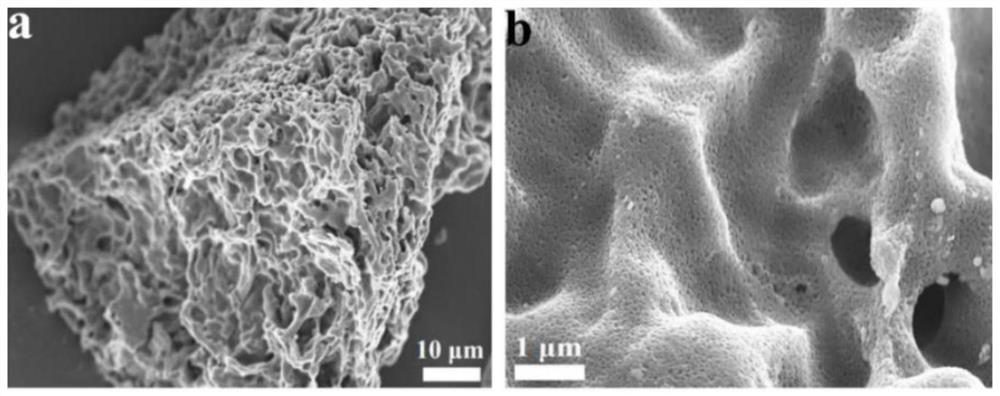

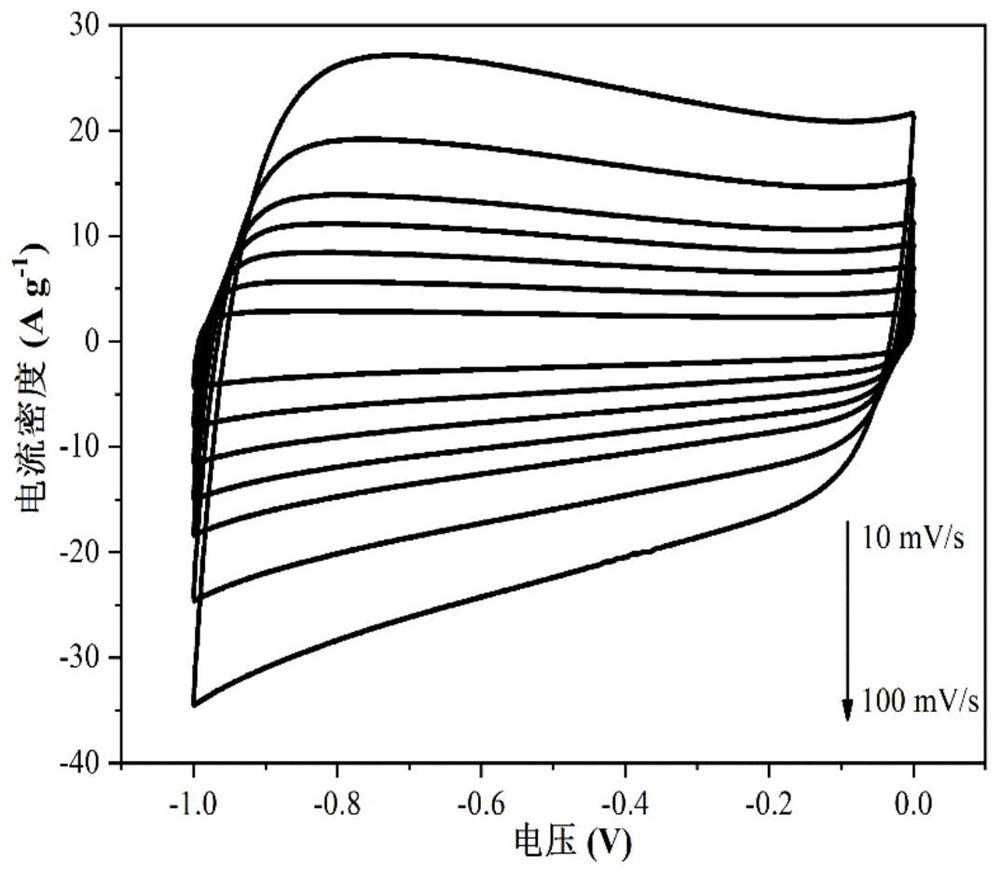

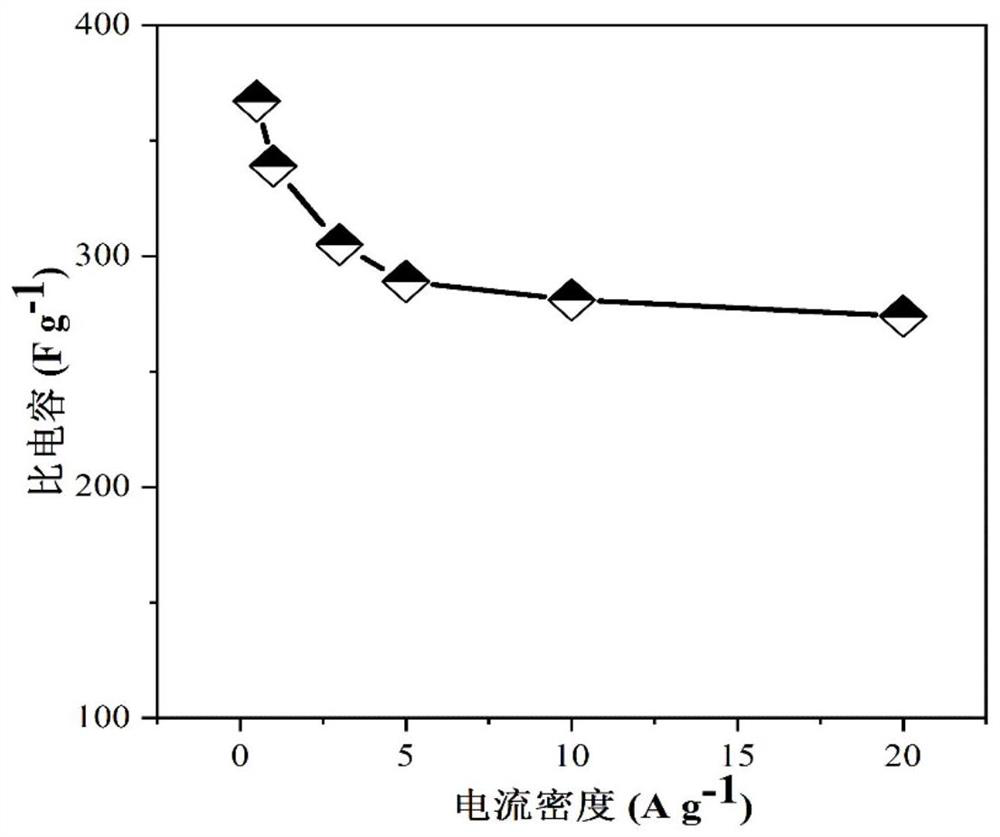

Biomass porous carbon nanofoam as well as preparation method and application thereof

A nano-foam, biomass technology, applied in nanotechnology, chemical instruments and methods, carbon compounds, etc., can solve the problems of cumbersome purification, environmental pollution, etc., and achieve the effects of low price, improved hydrophilicity, and a wide range of sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation method of the biomass porous carbon nanofoam of the present embodiment includes the following steps:

[0032] (1) 10g of bamboo fungus was placed in an autoclave, pre-carbonized at 100°C for 12h after cleaning, dried at 80°C for 10h, and then ground to obtain product A;

[0033] (2) after product A is mixed with the mixed activator of basic zinc carbonate and urea, product B is obtained after grinding 15min; wherein, the mass ratio of product A, basic zinc carbonate and urea is 2:1:2.

[0034] (3) Under the protection of inert gas, the product B is heated to 750°C at 5°C / min, and carbon nanofoam is obtained after carbon activation reaction for 2h, centrifugal cleaning and drying.

Embodiment 2

[0036] The preparation method of the biomass porous carbon nanofoam of the present embodiment includes the following steps:

[0037] (1) 10g of bamboo fungus was placed in an autoclave, pre-carbonized at 150°C for 24h after cleaning, dried at 100°C for 12h, and then ground to obtain product A;

[0038] (2) after product A is mixed with the mixed activator of basic zinc carbonate and urea, product B is obtained after grinding 15min; wherein, the mass ratio of product A, basic zinc carbonate and urea is 2:1:1.

[0039] (3) Under the protection of inert gas, the product B was heated to 850°C at 5°C / min, and carbon nanofoam was obtained after carbon activation reaction for 1 h, centrifugal cleaning and drying.

Embodiment 3

[0041] The preparation method of the biomass porous carbon nanofoam of the present embodiment includes the following steps:

[0042] (1) 10g of bamboo fungus was placed in an autoclave, pre-carbonized at 200°C for 48h after cleaning, dried at 120°C for 5h, and then ground to obtain product A;

[0043] (2) after product A is mixed with the mixed activator of basic zinc carbonate and urea, product B is obtained after grinding 15min; wherein, the mass ratio of product A, basic zinc carbonate and urea is 2:2:1.

[0044] (3) Under the protection of inert gas, the product B is heated to 900°C at 5°C / min, and carbon nanofoam is obtained after carbon activation reaction for 0.5h, centrifugal cleaning and drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com