Multifunctional ceramic and manufacturing method and application thereof

A manufacturing method, multi-functional technology, applied in the direction of ceramic products, applications, manufacturing tools, etc., can solve problems such as limited choice of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

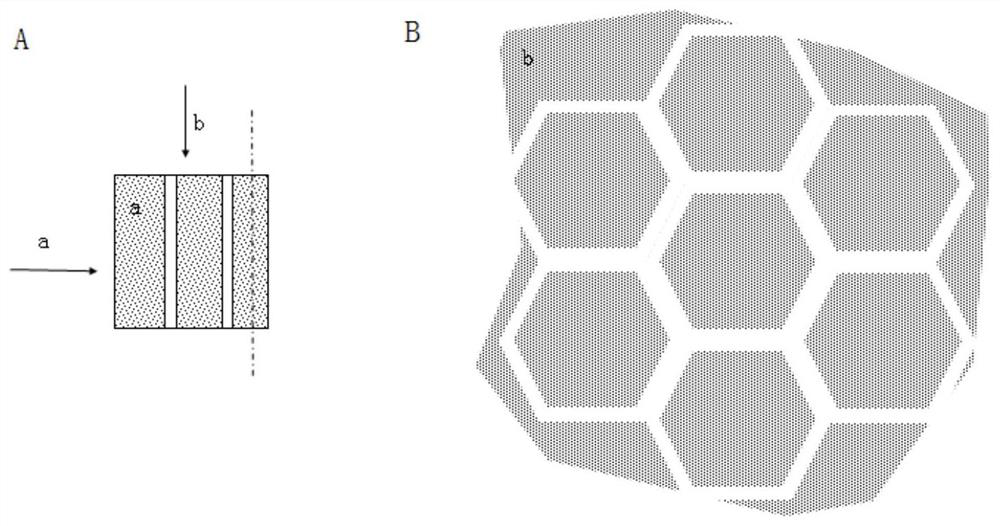

[0174] 3. The preparation process of these multifunctional ceramics is different from the traditional preparation process and will include additional steps, which include the integration of the core material into the prepared initial ceramic slurry (also called ceramic green body), and the sintering process. Extra steps. The present invention provides the basic steps to be followed in the preparation of multifunctional ceramics, starting from the traditional method of combining refractory powders and then sintering, but does not exclude other potential routes and preparation methods that can be simply changed to achieve the same result.

[0175] The design of multifunctional materials can be performed using one of many commercially available numerical simulation software (such as Ansys, Comsol, HFSS, etc.), and in the case of simpler configurations, can even be derived intuitively (based on field experience) or theoretically. Once the ceramic refractory powder and core materia...

Embodiment 1

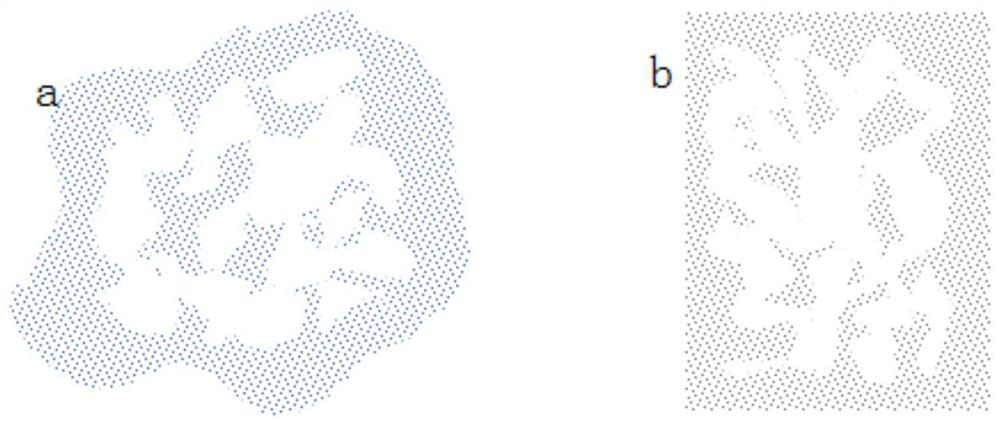

[0283] A preparation method of ultra-light glass foam with periodic porous pores:

[0284] Ceramic powder composition: low-temperature sintered ceramic mixed powder (LTCC, mainly Al, Si, B\mainly alumina, boron, silicon dioxide, may also add magnesium, cobalt, nickel or selenium);

[0285] Core material: PP (polypropylene) core with circular unit cells;

[0286] Ethanol (C 2 h 6 O) and methyl ethyl ketone (MEK) mass ratio is the solution of 70:30, and both are mixed. Divide low-temperature sintered ceramic mixed powder (LTCC, mainly Al, Si, B\mainly alumina, boron, silicon dioxide, and possibly magnesium, cobalt, nickel or selenium) with a sintering temperature of 800-900 °C into two Step addition: first add 31.35g powder and mix, then add 187.44g and mix. 218.79 g powder was prepared in 108.48 g ethanol / MEK solution.

[0287] In the first compound, 10.76 g of PVB (polybutyral C 8 h 14 o 2 ). The solution contained 25 parts PVB, 125 parts (MEK / ethanol solution). Typi...

Embodiment 2

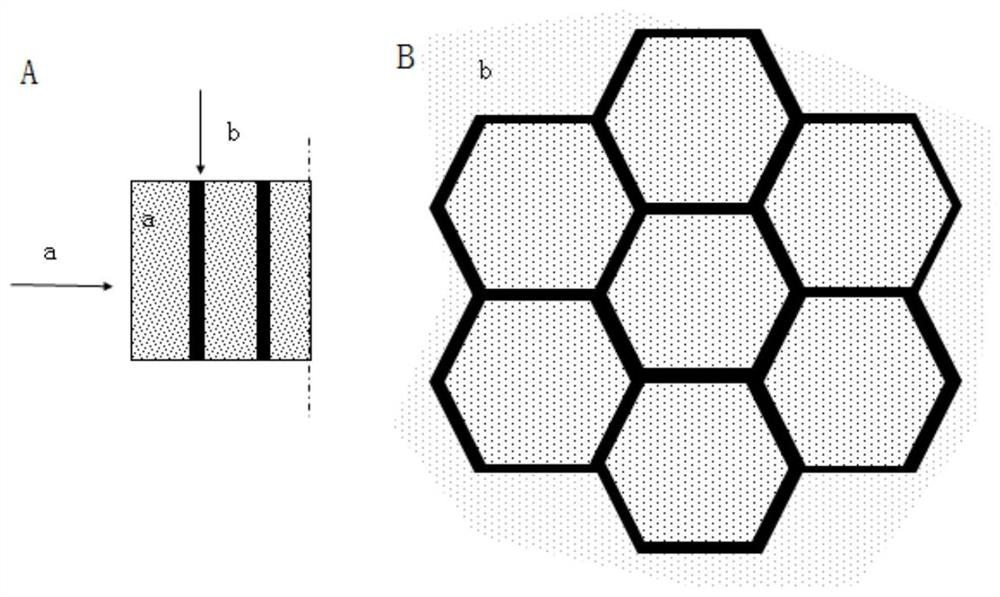

[0296] A kind of preparation method of dense glass (LTCC ceramics) of honeycomb porosity:

[0297] Ceramic powder composition: low temperature sintered ceramic mixed powder (LTCC);

[0298] Core material: epoxy resin core of honeycomb unit cell;

[0299] 20g LTCC glass powder, 2% PAA, 70:30 ethanol and MEK solution (2% PVB), mixed.

[0300] Add ceramic powder, dispersant and other fillers to the honeycomb core when a certain uniform water-based consistency is obtained. The ceramic slurry is allowed to dry and then compressed. Sintering process:

[0301] 1. 5°C / min, reach 50% sintering temperature (400°C) within 4 hours, burn core and remove gas;

[0302] 2. Maintain a stable temperature at 500°C for 1 hour to remove all gas in the sample;

[0303] 3. Rise to 800°C and reach the final temperature within 3 hours;

[0304] 4. Stabilize at 800°C for 2 hours, then cool.

[0305] A dense glass with cellular porosity was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com