Method for treating byproducts in process for preparing chloropropene by propylene chlorination

A technology of chlorination to produce allyl chloride and a treatment method, which is applied in the field of treatment of by-products in the chlorination of propylene to allyl chloride process, can solve the problems of unawareness of economic value and low added value of products, and achieves improved selectivity and conversion. High efficiency, high indexing efficiency and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

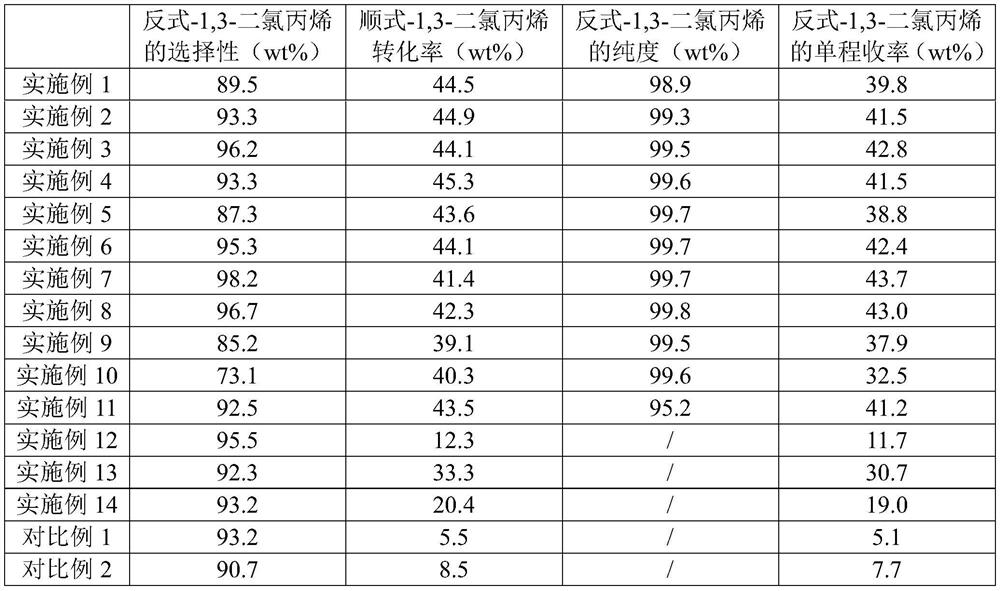

Embodiment 1

[0068] This embodiment provides a method for treating by-products in the process of producing propylene chloride by chlorination of propylene, the method comprising the following steps:

[0069] (1) Multi-stage rectification and separation of by-products in the process of producing chloropropene by chlorination of propylene to obtain cis-1,3-dichloropropene, and the purity of the cis-1,3-dichloropropene is 99.2wt%;

[0070] Wherein, the mass percentage of 1,2-dichloropropane in the by-product is 60wt%, the mass percentage of trans-1,3-dichloropropene is 14wt%, and the cis-1,3-dichloropropene is 14wt%. The mass percentage composition of allyl chloride is 16wt%;

[0071] (2) Mix the cis-1,3-dichloropropene described in step (1) with methanol, the concentration of the cis-1,3-dichloropropene in methanol is 80wt%, in 500mL quartz glass IV Add 100mL of the mixture of cis-1,3-dichloropropene and methanol into the mouth bottle, then add 2.4g of bromine as a catalyst, and irradiate w...

Embodiment 2

[0074] This embodiment provides a method for treating by-products in the process of producing allyl chloride by chlorination of propylene. In the method, except that in step (2), the "ultraviolet light irradiation for 4 hours" is replaced by "ultraviolet light irradiation for 8 hours", the rest are all Same as Example 1.

Embodiment 3

[0076] This embodiment provides a method for treating by-products in the process of producing propylene chloride by chlorination of propylene, the method comprising the following steps:

[0077] (1) Multi-stage rectification and separation of by-products in the process of producing chloropropene by chlorination of propylene to obtain cis-1,3-dichloropropene, and the purity of the cis-1,3-dichloropropene is 99.9wt%;

[0078] Wherein, the mass percentage of 1,2-dichloropropane in the by-product is 65wt%, the mass percentage of trans-1,3-dichloropropene is 18wt%, and the cis-1,3-dichloropropene is 18wt%. The mass percentage composition of allyl chloride is 19wt%;

[0079] (2) Mix the cis-1,3-dichloropropene described in step (1) with chlorobenzene, the concentration of the cis-1,3-dichloropropene in chlorobenzene is 80wt%, in 500mL quartz Add 100mL of a mixture of cis-1,3-dichloropropene and chlorobenzene into a glass four-neck flask, then add 2.4g of N-bromosuccinimide as a cat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com