Device for superspeed laser cladding manufacture and method

A technology of additive manufacturing and laser cladding, applied in the direction of using optical devices, manufacturing tools, additive manufacturing, etc., to achieve the effect of improving comprehensive performance, high processing efficiency, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

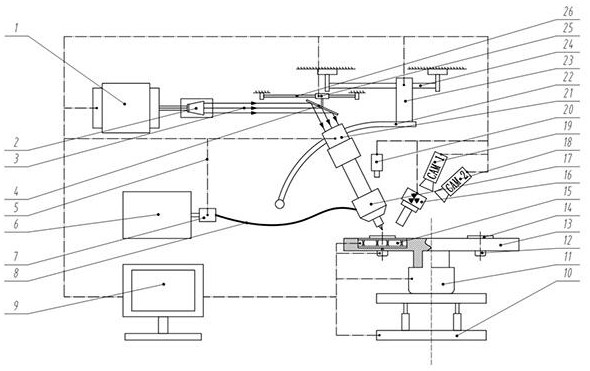

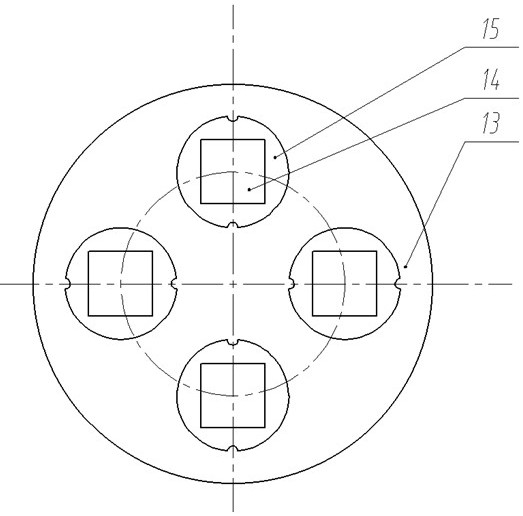

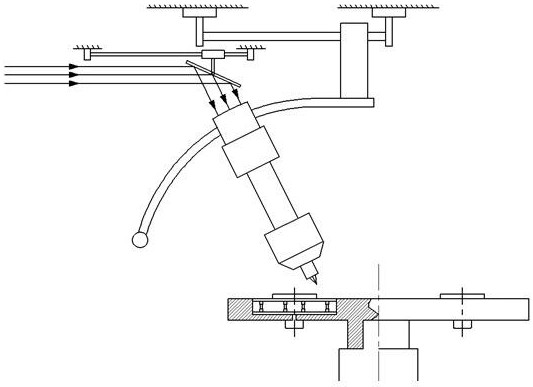

[0025] Such as figure 1 and figure 2As shown, an ultra-high-speed laser cladding additive manufacturing device provided in this embodiment includes a laser generator 1 and a beam expander 2 , and the beam expander 2 is used to expand the incident laser light into a parallel laser beam 3 . The parallel laser beam 3 enters the cladding nozzle 17 through the mirror 4 and is focused on the substrate 14 through the lens in the cladding nozzle. The cladding nozzle 17 is fixed on the electric slide block A21, and can move on the electric slide rail A22. The electric slide rail A22 is fixed on the electric slide block B23, and can move on the electric slide rail B24. The reflector 4 is connected with the electric slide block C25 through a rotating shaft and can move along the direction of the electric slide rail C26. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com