A kind of anti-corrosion agent for under-scale corrosion of oil field surface gathering and transportation pipeline and preparation method thereof

A technology for gathering and transportation pipelines and corrosion inhibitors, which is applied in the field of anti-corrosion under-scaling corrosion inhibitors for oilfield surface gathering and transportation pipelines and its preparation field, which can solve the problem of aggravating the degree of local corrosion of sediments, increasing the degree of local under-scaling corrosion, and economic losses and other problems, to achieve good corrosion inhibition performance, reduce corrosion, and add less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A corrosion inhibitor for preventing under-scaling corrosion of oilfield surface gathering and transportation pipelines, which consists of the following components and their mass percentages:

[0034] Rosin amine polyoxyethylene ether: 0.5%; nano-scale silicon dioxide: 0.1%; sodium tetraborate: 1%; tungstate: 0.5%, wherein the mass ratio of sodium tungstate and ammonium tungstate is 7:1; - Mercaptolauric acid: 5%; epoxysuccinic acid: 6%; ethanol: 2%; balance water.

[0035] Specific preparation method: first add water to the reaction kettle, then dissolve ethanol in water, then add the main agent of corrosion inhibitor, auxiliary agent of corrosion inhibitor, sodium tetraborate, tungstate and α-mercapto lauryl into the reaction kettle Acid and epoxy succinic acid substances were stirred for 2 hours, and the temperature of the reaction kettle was controlled at 50°C to completely dissolve to obtain a yellow transparent liquid product.

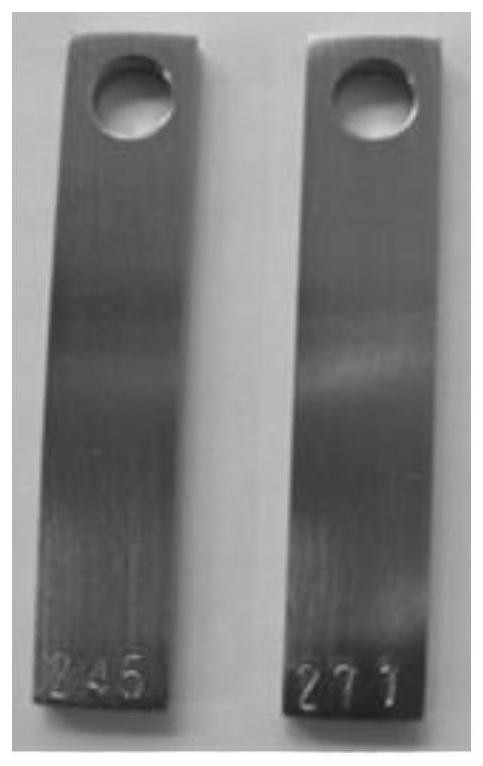

[0036] by comparing figure 2 and...

Embodiment 2

[0038] A corrosion inhibitor for preventing under-scaling corrosion of oilfield surface gathering and transportation pipelines, which consists of the following components and their mass percentages:

[0039] Rosin-based imidazoline quaternary ammonium salt: 12%; nano-scale silicon dioxide: 10%; sodium tetraborate: 14%; tungstate: 8%, wherein the mass ratio of sodium tungstate and ammonium tungstate is 7:6; α-mercaptolauric acid: 20%; sodium polyepoxysuccinate: 18%; ethanol: 8%; the balance is water.

[0040] Specific preparation method: first add water to the reaction kettle, then dissolve ethanol in water, then add the main agent of corrosion inhibitor, auxiliary agent of corrosion inhibitor, sodium tetraborate, tungstate and α-mercapto lauryl into the reaction kettle Acid and epoxy succinic acid substances were stirred for 1 hour, and the temperature of the reaction kettle was controlled at 55° C. to completely dissolve to obtain a yellow transparent liquid product.

Embodiment 3

[0042] A corrosion inhibitor for preventing under-scaling corrosion of oilfield surface gathering and transportation pipelines, which consists of the following components and their mass percentages:

[0043] Rosin-based imidazoline quaternary ammonium salt: 7%; nano-scale silicon dioxide: 4%; sodium tetraborate: 9%; tungstate: 3%, wherein the mass ratio of sodium tungstate and ammonium tungstate is 7:2; α-Mercaptolauric acid: 11%; epoxy succinic acid substances: 12%; ethanol: 4%; the balance is water.

[0044] Among them, the succinic acid substance is made by mixing epoxysuccinic acid and sodium polyepoxysuccinate, and the mixing ratio of epoxysuccinic acid and sodium polyepoxysuccinate is 3:1.

[0045] Specific preparation method: first add water to the reaction kettle, then dissolve ethanol in water, then add the main agent of corrosion inhibitor, auxiliary agent of corrosion inhibitor, sodium tetraborate, tungstate and α-mercapto lauryl into the reaction kettle Acid and e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com