Janus type material with one-way water transport property as well as preparation method and application of Janus type material

A water transmission, one-way technology, applied in the direction of separation methods, chemical instruments and methods, fiber types, etc., can solve the problems of complex operation, unfavorable wide application of Janus membrane, low efficiency, etc., and achieve simple preparation process and good industrial application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

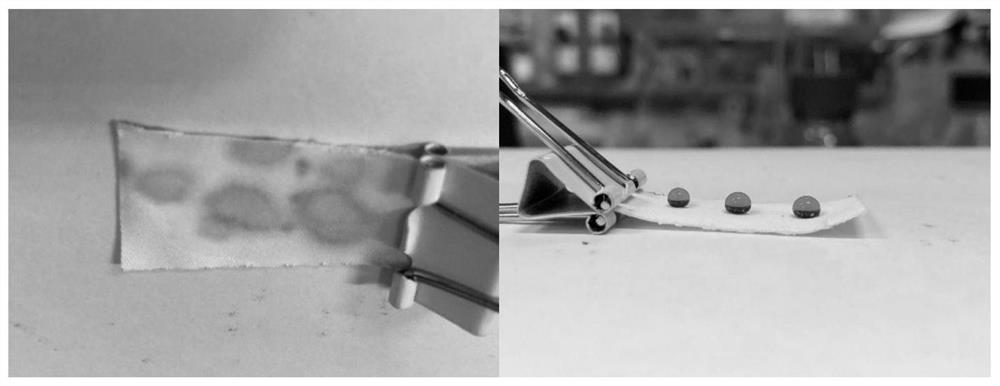

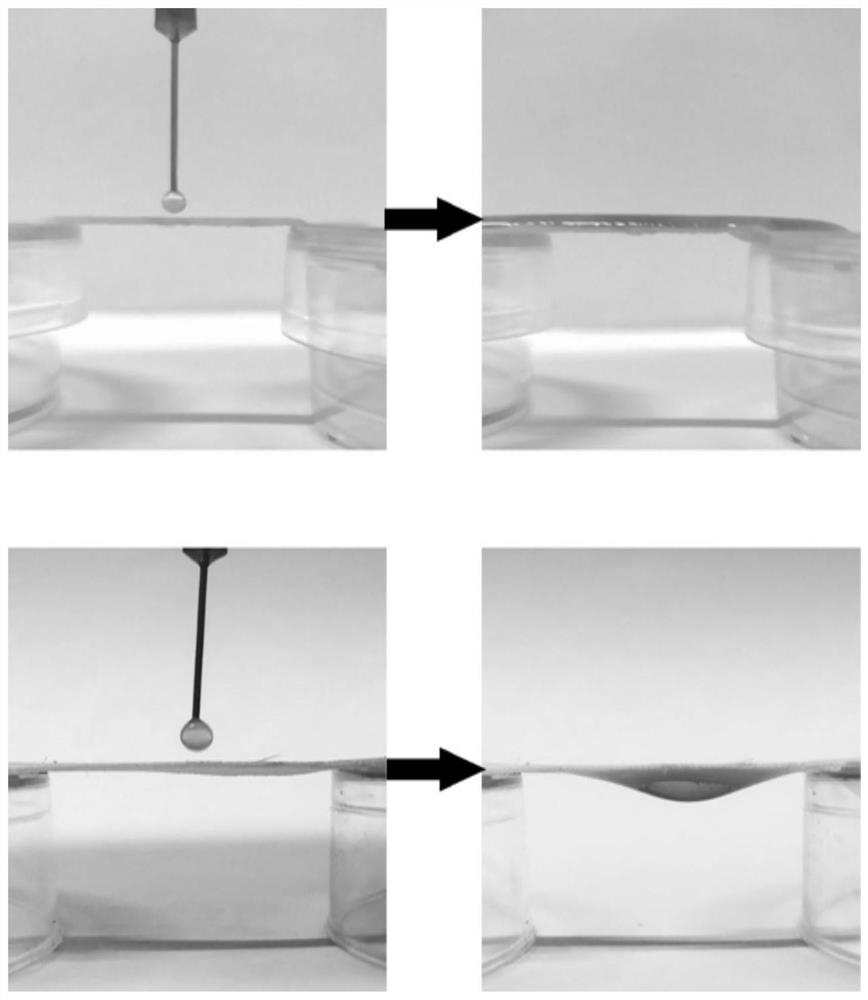

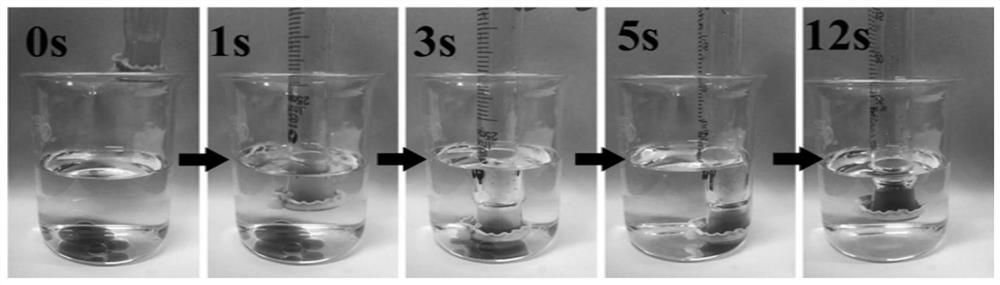

[0031] The preparation method of the Janus dust-free cloth of the present embodiment comprises the following steps:

[0032] 1. Immerse the dust-free arrangement in an aqueous solution containing phytic acid and ferric chloride for 1 hour. The concentration of phytic acid in the aqueous solution is 5mg / L, and the concentration of ferric chloride is 2mg / L;

[0033] 2. Take out the dust-free cloth from the aqueous solution, wash it with clean water, put it in deionized water and let it stand for 1 minute, then take it out and stick it on the glass;

[0034] 3. Spray the chloroform solution containing polydimethylsiloxane with the dust-free cloth of the glass sheet with the spray gun, and the mass percentage of polydimethylsiloxane in the chloroform solution containing polydimethylsiloxane is 2%. , the injection amount of chloroform containing polydimethylsiloxane is 2mL, the pressure of the spray gun is 0.5MPa, the injection speed is 1mL / s, and the Janus-type dust-free cloth is ...

Embodiment 2

[0037] The preparation method of the present embodiment Janus nylon cloth comprises the following steps:

[0038] 1. Immerse nylon in an aqueous solution containing tannic acid and ferric chloride for 2 hours. The concentration of tannic acid is 10 mg / L, and the concentration of ferric chloride is 5 mg / L;

[0039] 2. Take out the nylon cloth from the aqueous solution, wash it with clean water, put it in deionized water and let it stand for 1 minute, then take it out and stick it on the glass;

[0040] 3. Use the spray gun to aim at the nylon cloth on the glass sheet and spray the dichloromethane solution of polydimethylsiloxane. The mass percentage of polydimethylsiloxane in the dichloromethane solution containing polydimethylsiloxane is 2%, the injection amount of dichloromethane containing polydimethylsiloxane is 4mL, the pressure of the spray gun is 0.5MPa, the injection speed is 0.5mL / s, and then dried to obtain Janus nylon cloth.

[0041] The water contact angle of the J...

Embodiment 3

[0043] The preparation method of the present embodiment Janus filter paper comprises the following steps:

[0044] 1. Immerse the filter paper in an aqueous solution containing chlorogenic acid and ferric chloride for 0.5 hours, the concentration of chlorogenic acid is 1 mg / L, and the concentration of ferric chloride is 1 mg / L;

[0045] 2. Take out the filter paper from the aqueous solution, wash it with clean water, put it in deionized water and let it stand for 1 minute, then take it out and stick it on the glass slide;

[0046] 3. Use a spray gun to aim at the filter paper on the glass sheet and spray the chloroform solution of polydimethylsiloxane. The mass percentage of polydimethylsiloxane in the chloroform solution containing polydimethylsiloxane is 3%. The injection volume of chloroform of dimethylsiloxane was 3 mL, the pressure of the spray gun was 0.5 MPa, and the injection speed was 0.5 mL / s, and then dried to obtain Janus type filter paper.

[0047] The water cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com