Visible-light-driven self-cleaning graphene oxide oil-water separation membrane as well as preparation method and application thereof

An oil-water separation membrane and graphene dispersion technology, applied in the field of material chemistry, can solve the problems of reducing the service life of oil-water separation membranes, limiting the practical application of membrane separation technology, blocking membrane pores, etc. The effect of cleaning ability, good hydrophilic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

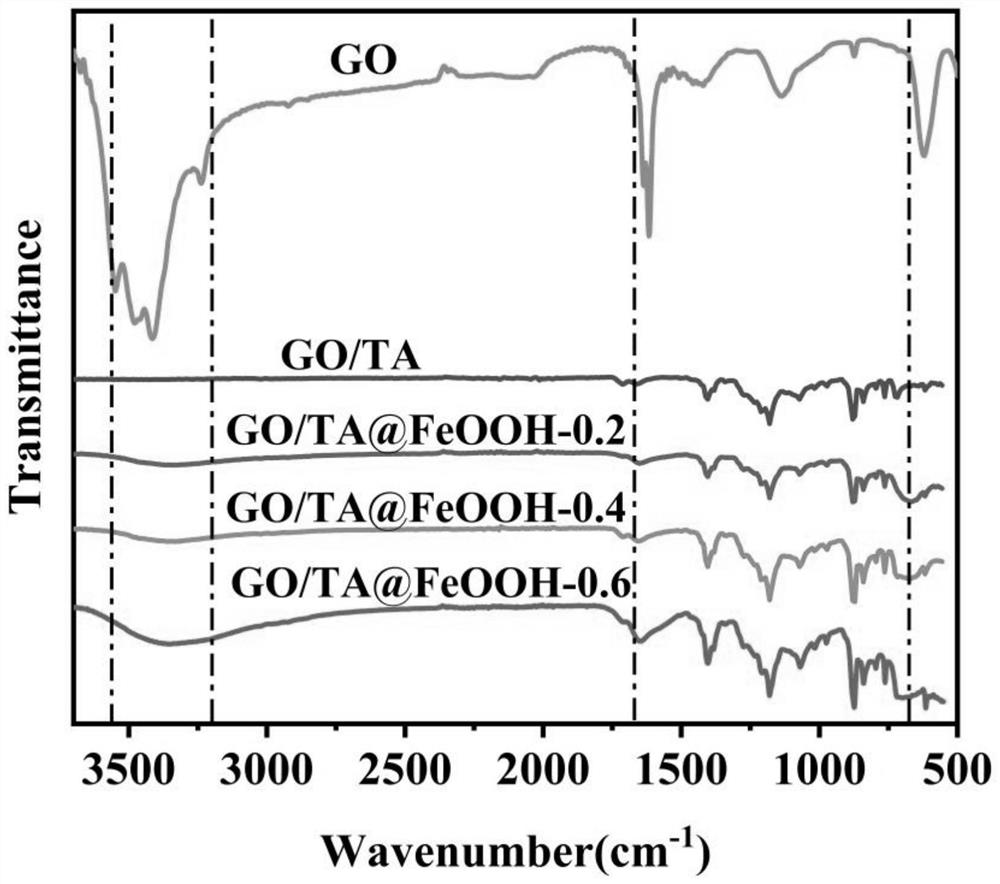

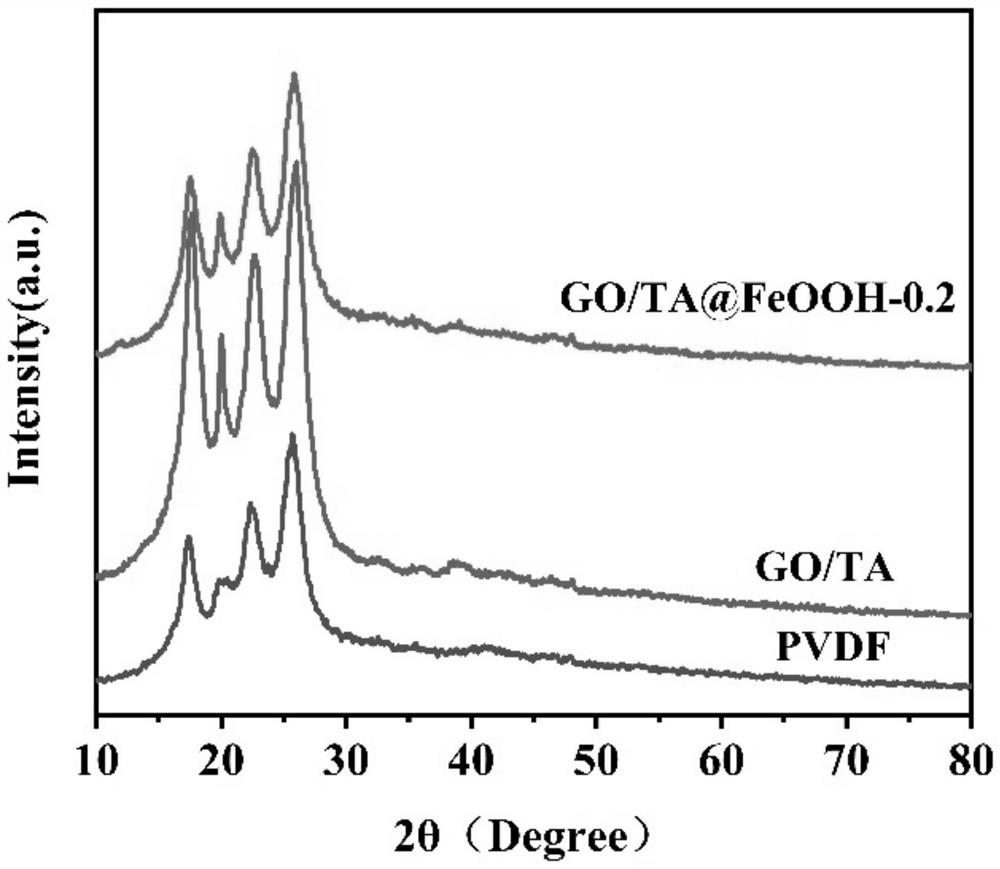

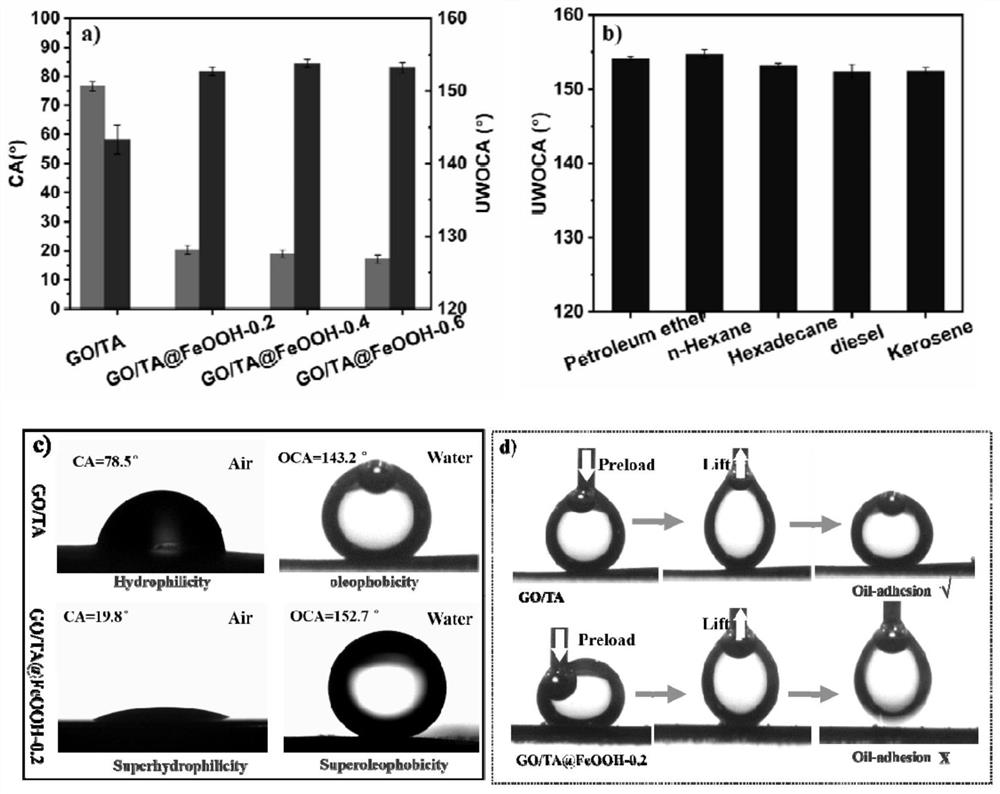

[0037] This embodiment provides a method for preparing a visible light-driven self-cleaning graphene oxide oil-water separation membrane, comprising the following steps:

[0038] S1. Preparation of GO / TA composite membrane

[0039] Add 0.10g-0.14g of tannic acid (TA) and 0.8ml-1.2ml of graphene oxide dispersion (the content of graphene oxide powder is 40mg-60mg) into 100mL of deionized water, and disperse with ultrasound for 15min- After 25min, add 0.1g-0.3g FeCl to the above mixed solution 3 ·6H 2 O, stirred at room temperature for 5 min. Take 2 mL of the above solution and pump a membrane (hydrophilic, PVDF membrane, 0.22 μm) to prepare a tannic acid-modified graphene oxide composite membrane (GO / TA composite membrane).

[0040] S2. Preparation of GO / TA@FeOOH-x composite membrane

[0041] The GO / TA composite membrane was transferred to a concentration of 0.2wt%-0.6wt% ferric chloride (FeCl 3 ·6H 2 O) solution, place the solution in an oven at 50°C-70°C for 5h-7h. Afte...

Embodiment 1

[0043] Preparation of GO / TA Composite Membranes

[0044] Add 0.12 g of tannic acid (TA) and 1 ml of graphene oxide dispersion (wherein the content of graphene oxide powder is 50 mg) into 100 mL of deionized water, disperse with ultrasound for 20 min, and then add 0.2 g of FeCl 3 ·6H 2 O, stirred at room temperature for 5 min. Take 2 mL of the above solution and pump a membrane (hydrophilic, PVDF membrane, 0.22 μm) to prepare a tannic acid-modified graphene oxide composite membrane (GO / TA composite membrane).

Embodiment 2

[0046] Preparation of GO / TA@FeOOH-0.2 Composite Membrane

[0047] The GO / TA composite membrane prepared in Example 1 was transferred to a concentration of 0.2wt% ferric chloride (FeCl 3 ·6H 2 O) solution, the solution was placed in an oven at 60°C for 6h. After the composite membrane was taken out, it was washed with deionized water and dried in a vacuum oven at 40 °C for 24 h to prepare the GO / TA@FeOOH-0.2 composite membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com