Nanofiber composite membrane for liquid-liquid membrane extraction process and preparation method thereof

A technology of nanofibers and composite membranes, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve problems such as progress obstacles, lack of long-term stability of extraction membranes, etc., and achieve excellent corrosion resistance, excellent long-term stability, excellent selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

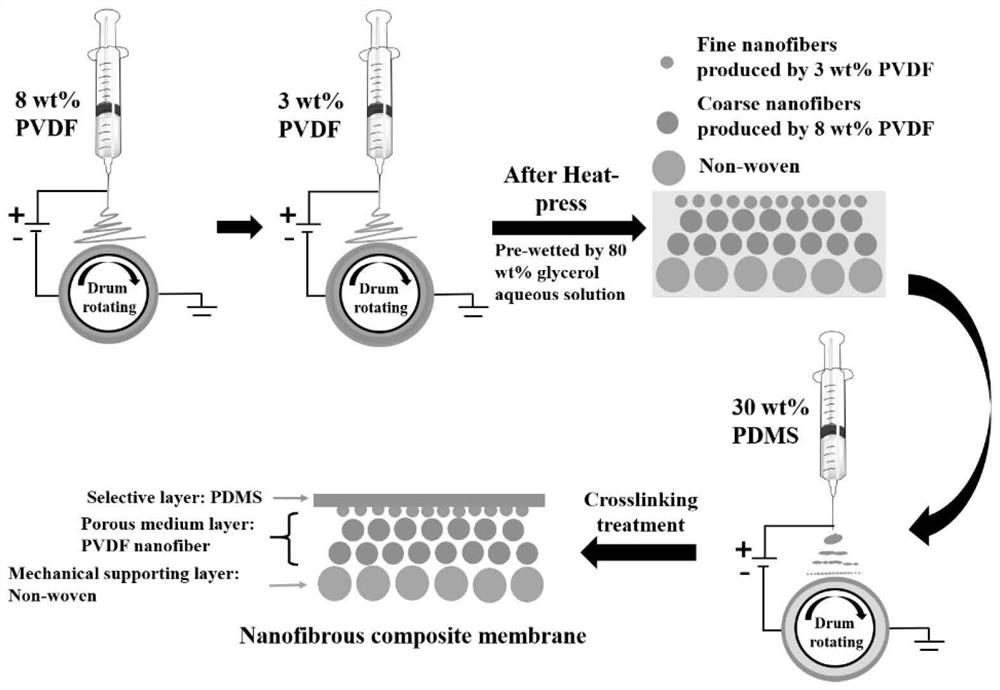

Method used

Image

Examples

Embodiment 1

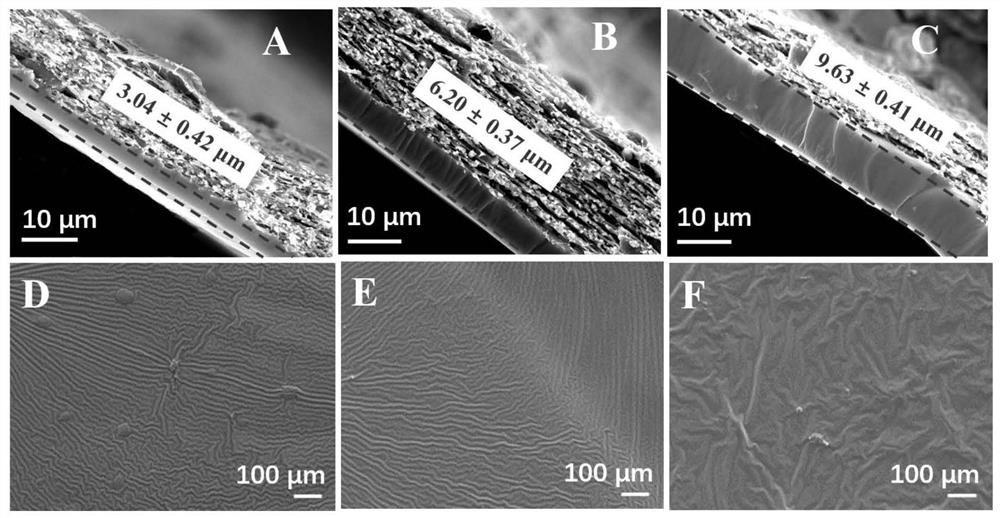

[0031] In order to precisely control and minimize the thickness of the PDMS selective layer, an electrostatic spray printing technology was proposed to achieve precise control of the thickness of the PDMS selective layer. By controlling the electrostatic spray printing time of 30wt% PDMS solution, PDMS selective layers with three different thicknesses were prepared on the PVDF / nonwoven support layer. The thicknesses of the PDMS selective layers of the three composite membranes are 3.0±0.4μm, 6.2±0.4μm and 9.6±0.4μm respectively, and the corresponding electrostatic spraying times are 40min, 80min and 120min, respectively named #N3-1 and #N3-2 and #N3-3, the plane and cross-sectional SEM images of the three composite membranes are shown in image 3 . The thickness of the PDMS selective layer can be as low as 3.0 μm. This result shows that the precise control of the thickness of the PDMS selective layer can be achieved by electrostatic spray printing technology.

Embodiment 2

[0033]By applying to the three composite membranes (#N3-1, #N3-2 and #N3-3) obtained in Example 1 Figure 4 The liquid-liquid extraction device shown was used to test the phenol mass transfer effect of three composite membranes. The experimental results are as follows: Figure 5 As shown, the phenol mass transfer efficiency of the three composite membranes gradually decreases with the increase of the selective thickness, and the phenol mass transfer coefficient (k 0 ) can reach 37.9±2.8×10 -7 m / s, excellent rejection rate above 99.95%. The results of this example show that the electrospinning and electrostatic spray printing technologies are effective ways to prepare nanofiber composites with high organic mass transfer efficiency and excellent selectivity for the liquid-liquid membrane extraction process.

Embodiment 3

[0035] By the nanofiber composite #N3-1 with high organic mass transfer efficiency and excellent selectivity obtained in Example 1 according to Figure 4 The shown liquid-liquid extraction device has carried out 105 hours of continuous phenol mass transfer tests, the results are as follows Figure 6 As shown in A, the composite membrane maintained a very high phenol k throughout the test process. 0 Value (37.9±2.8×10 -7 ), the retention rate also remains above 99.95%. This example shows that the composite membrane prepared by the invention has excellent long-term stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com