Novel biochemical treatment method for removing heavy metals in sewage by strengthening composite carrier

A composite carrier and biochemical treatment technology, which is applied in the field of sewage treatment, can solve the problems that the discharge water is difficult to meet the national discharge standard, the natural flocculation and sedimentation takes a long time, and the types of heavy metal ions are complex, so as to shorten the time from start-up to normal and stable operation. The effect of shortening the microbial culture time and increasing the initial concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

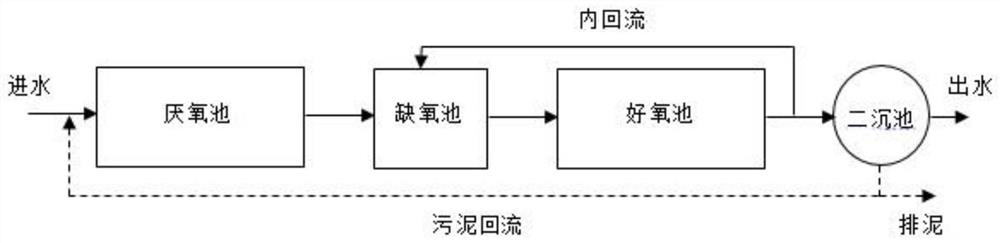

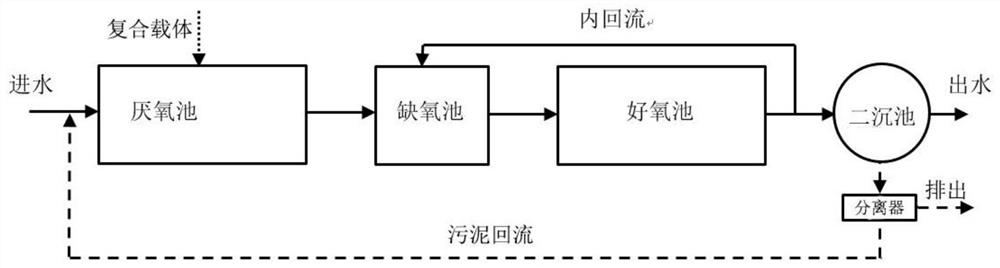

[0026] Such as figure 1 As shown, a novel composite carrier strengthens the biochemical treatment method for removing heavy metals in sewage, including the following steps:

[0027] (1) Mix diatomite and tourmaline at a mass ratio of 9:1, grind and sieve the obtained mixture to obtain a composite carrier powder with a particle size of 10-200 μm, then soak the composite carrier in raw sewage water, stir, and wait After the composite carrier completely absorbs moisture (no longer agglomerating and floating), the composite carrier slurry is obtained;

[0028] (2) Use a pH regulator to adjust the composite carrier slurry to 7 to 8, and then spray the composite carrier slurry into the anaerobic tank in the AAO biological treatment device through a directional spray device; wherein, the composite carrier is in the anaerobic tank The ratio of the daily dosing quality in the medium to the total effective volume of the AAO biological treatment device is 2g: 1L;

[0029] (3) Start the...

Embodiment 2

[0036] A novel composite carrier strengthens the biochemical treatment method for removing heavy metals in sewage, comprising the following steps:

[0037] (1) Mix diatomite and tourmaline at a mass ratio of 9:1, grind and sieve the obtained mixture to obtain a composite carrier powder with a particle size of 10-200 μm, then soak the composite carrier in raw sewage water, stir, and wait Composite carrier slurry is obtained after the composite carrier completely absorbs moisture;

[0038] (2) Use a pH regulator to adjust the composite carrier slurry to 7-8, then mix the composite carrier slurry with activated sludge to obtain a mixed solution, and then spray the mixed solution to the AAO biological treatment device through a directional spray device In the anaerobic tank; wherein, the ratio of the daily dosage of the composite carrier in the anaerobic tank to the total effective volume of the AAO biological treatment device is 3g: 1L;

[0039](3) Start the AAO biological treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com