High-efficiency cement chromium-removing grinding aid

A grinding aid and cement technology, applied in the field of cement admixtures, can solve the problems of unreliable reduction of hexavalent chromium and low removal rate of hexavalent chromium, and achieve the effects of low cost, good use effect and low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

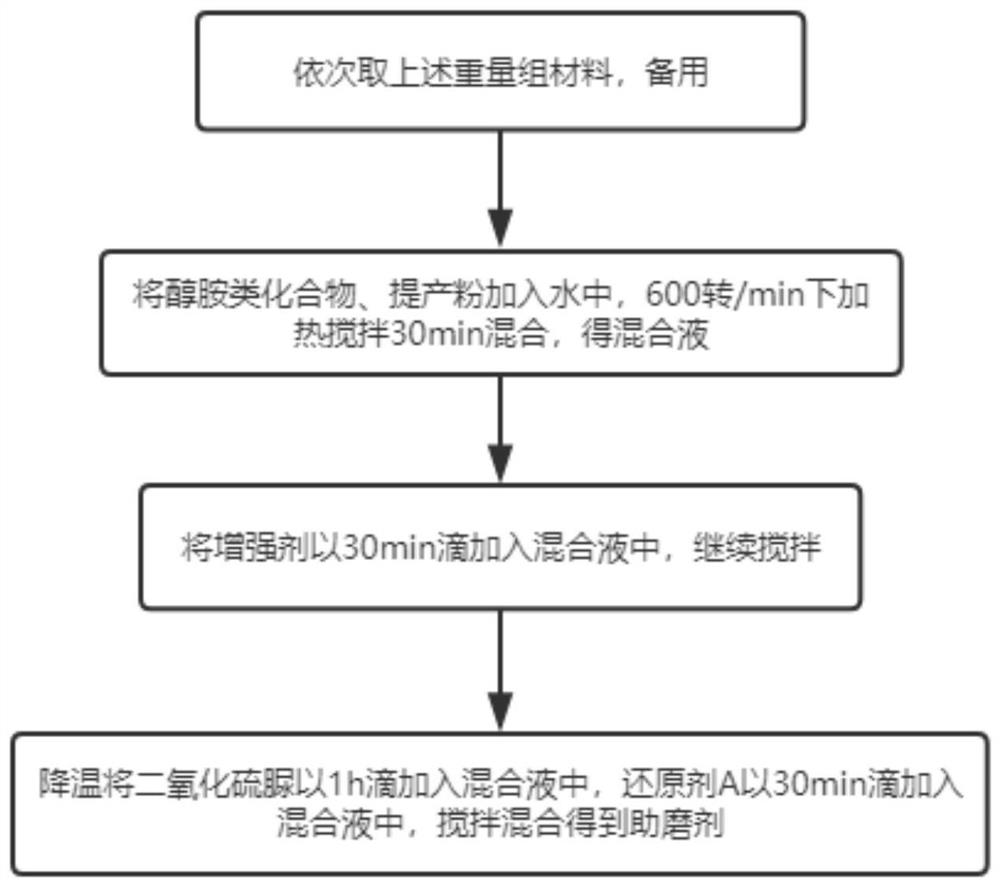

[0032] Efficient cement dechrome grinding aids, such as figure 1 As shown, it includes the following components by weight: 20% of water, 30% of alcohol amine compounds, 49% of extraction powder, 0.4% of reinforcing agent, and 0.6% of reducing agent.

[0033] The alcohol amine compound is triethanolamine, the raw material has a wide application range and low cost.

[0034] The preparation method of described enhancing agent, comprises the steps:

[0035] S21: Take 65% of aluminum slag, 12% of silicon sludge, 13% of carbide slag and 10% of wet fly ash, mix and stir evenly;

[0036] S22: Put the mixture into the billet forming machine to form billets;

[0037] S23: aging the formed product for 24 hours and then drying to remove ethylene glycol to form tricalcium aluminate;

[0038] S24: crush the dried material, send it to a dryer for 30 minutes, and control the drying temperature at 300-350°C;

[0039] S25: Cooling pack.

[0040] The reducing agent is 0.1% of thiourea dioxi...

Embodiment 2

[0050] Efficient cement dechrome grinding aids, such as figure 1 As shown, it includes the following components by weight: 20% of water, 20% of alcohol amine compounds, 59.2% of extraction powder, 0.3% of reinforcing agent, and 0.5% of reducing agent.

[0051] The alcohol amine compound is triethanolamine, the raw material has a wide application range and low cost.

[0052] The preparation method of described enhancing agent, comprises the steps:

[0053] S21: Take 65% of aluminum slag, 12% of silicon sludge, 13% of carbide slag and 10% of wet fly ash, mix and stir evenly;

[0054] S22: Put the mixture into the billet forming machine to form billets;

[0055] S23: aging the formed product for 24 hours and then drying to remove ethylene glycol to form tricalcium aluminate;

[0056] S24: crush the dried material, send it to a dryer for 30 minutes, and control the drying temperature at 300-350°C;

[0057] S25: Cooling pack.

[0058] The reducing agent is 0.1% of thiourea dio...

Embodiment 3

[0067] Efficient cement dechrome grinding aids, such as figure 1 As shown, it includes the following components by weight: 15% of water, 25% of alcohol amine compounds, 59.1% of extraction powder, 0.5% of reinforcing agent, and 0.4% of reducing agent.

[0068] The alcohol amine compound is triethanolamine, the raw material has a wide application range and low cost.

[0069] The preparation method of described enhancing agent, comprises the steps:

[0070] S21: Take 65% of aluminum slag, 12% of silicon sludge, 13% of carbide slag and 10% of wet fly ash, mix and stir evenly;

[0071] S22: Put the mixture into the billet forming machine to form billets;

[0072] S23: aging the formed product for 24 hours and then drying to remove ethylene glycol to form tricalcium aluminate;

[0073] S24: crush the dried material, send it to a dryer for 30 minutes, and control the drying temperature at 300-350°C;

[0074] S25: Cooling pack.

[0075] The reducing agent is 0.1% of thiourea dio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com