Efficient method for producing low-carbon olefin from oxygen-containing compound

A technology for low-carbon olefins and compounds, which is applied in the field of high-efficiency oxygenated compounds to produce low-carbon olefins, can solve the problems of low selectivity of low-carbon olefins and low ratio of agent to alcohol, etc., so as to improve the selectivity of low-carbon olefins and improve the selectivity , the effect of reducing the occurrence of unintended reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

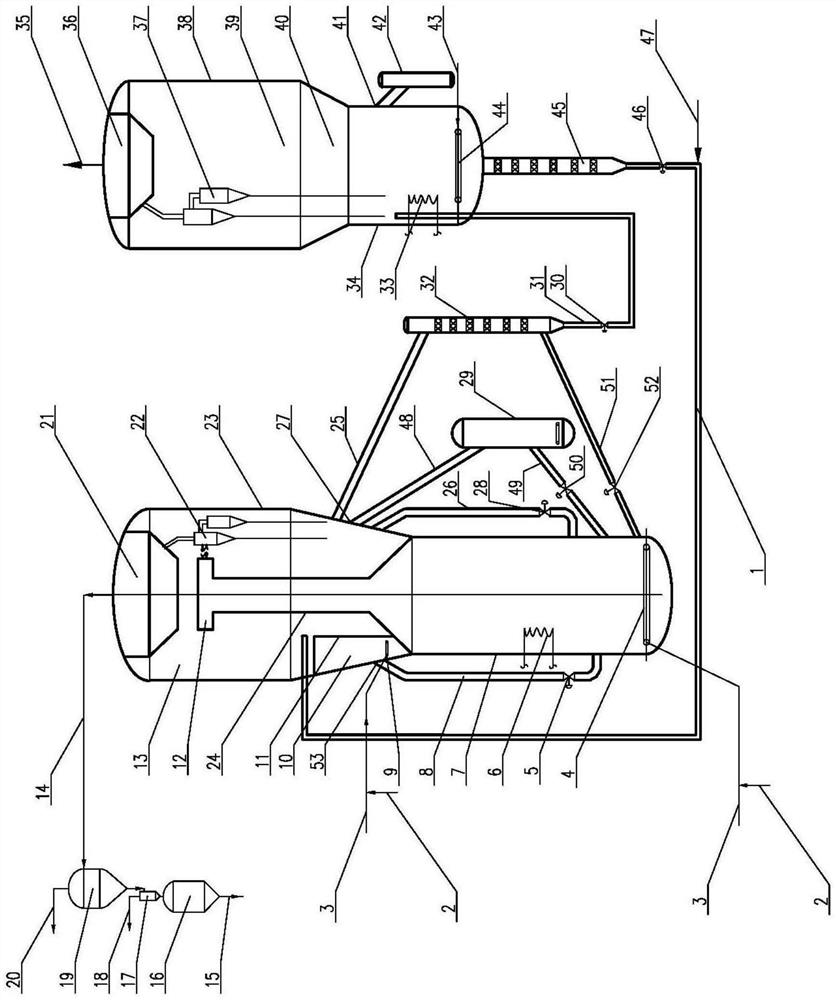

[0052] as attached figure 1 As shown, in the present invention a kind of high-efficient oxygenated compound produces the method for light olefin, comprises reactor 23, regenerator 38, reactor three-stage cyclone separator 19, reactor four-stage cyclone separator 17, reactor three The recovery catalyst storage tank 16, the standby stripper 32, the regenerative stripper 45, the heat extractor 29 outside the main reaction zone and the heat extractor 42 outside the regenerator. The reactor 23 includes a main reaction zone 7 , an auxiliary reaction zone 10 and a catalyst collection zone 13 , the main reaction zone 7 of the reactor is located below the catalyst collection zone 13 , and the auxiliary reaction zone 10 is located above the main reaction zone 7 . The main reaction zone 7 is connected to the catalyst collection zone 13 through a dilute-phase pipe 24. The top of the dilute-phase pipe 24 is provided with a catalyst rapid separation device 12, and the outlet of the catalyst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com